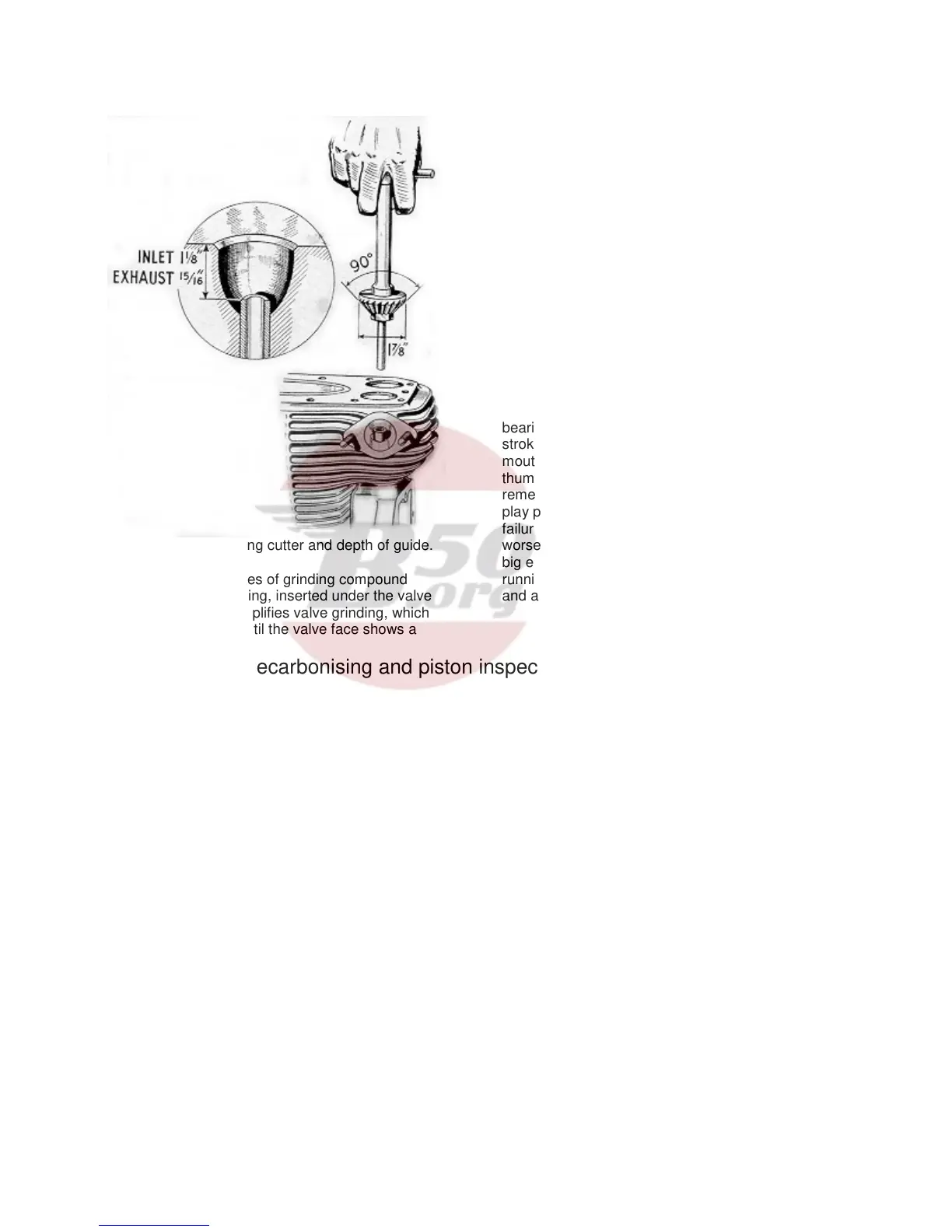

will wear away the seat in the cylinder barrel and

cause the valve to become pocketed. Take great

Fig. 14. Valve seating cutter and depth of guide.

care to remove all traces of grinding compound

afterwards. A light spring, inserted under the valve

head, considerably simplifies valve grinding, which

should be continued until the valve face shows a

smooth surface all the way round. If the machine has

covered a considerable mileage, the valve springs

may need replacing. Refit the valves, springs and

cotters with the aid of the tool shown in Fig. 12 after

valve stems have been lubricated.

PISTON AND RINGS. The gudgeon pin is located

by means of wire circlips which must be removed by

means of a tang of a file or similar tool. Withdraw the

gudgeon pin, thus freeing the piston and immediately

after its removal mark the inside of the piston so that

it can be re-assembled in its original position.

If inspection of the piston rings shows that they are

stuck, prise them out very carefully, and clean them.

Remove any carbon from the grooves and rings, but

before replacing them, check the gap with a ring in

the cylinder. If the gap is excessive, new rings must

be fitted having gaps of between .008” and .012”

when in position.

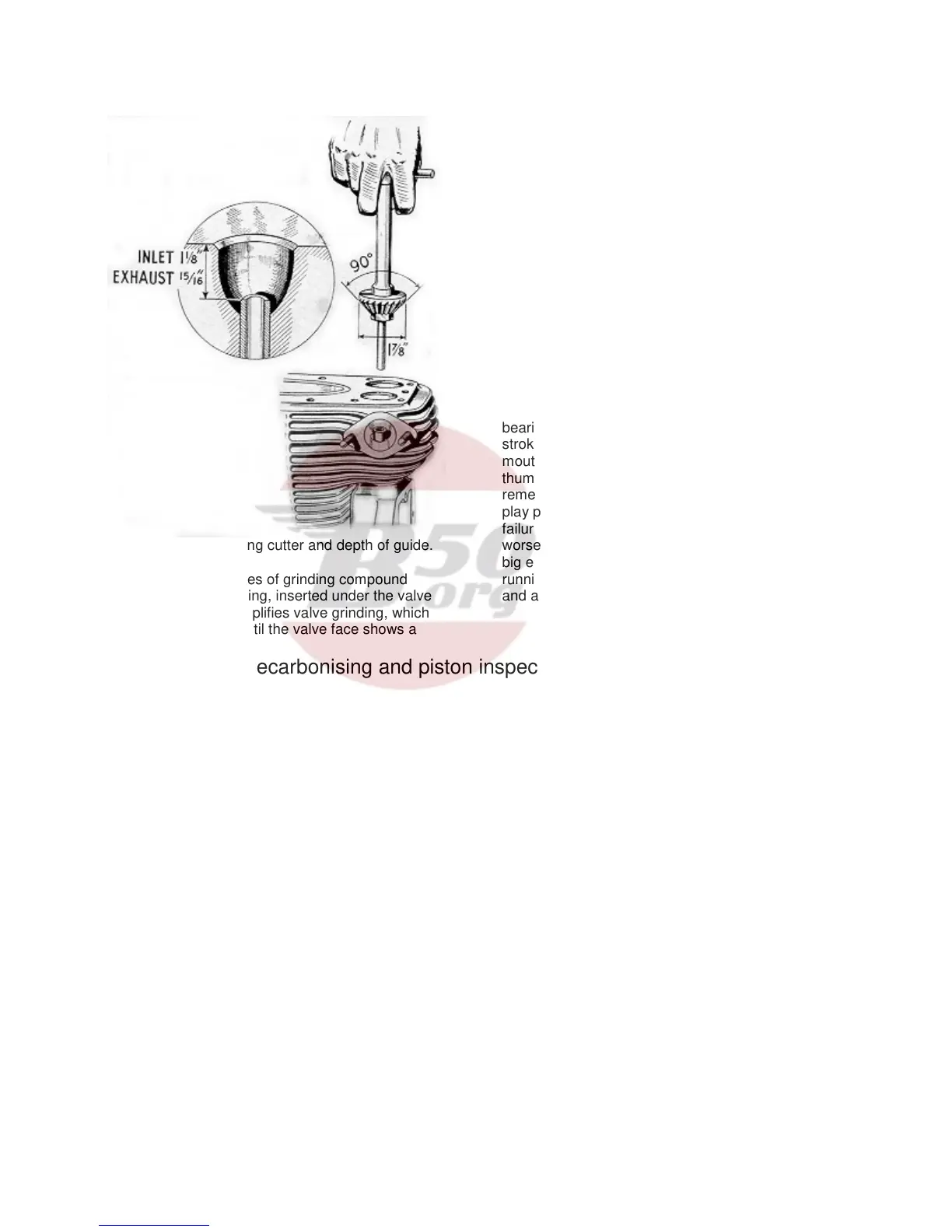

At this stage it is advisable to check the big end

bearing for wear. Turn engine until piston is at top of

stroke, and resting both hands on sides of crankcase

mouth, hold connecting rod between fingers and

thumbs and feel for up and down play. It should be

remembered that, even though there may be a little

play present, it will not necessarily mean sudden

failure of the bearing, though it will inevitably become

worse. Where play seems excessive, and apparent

big end noise has been noticed when engine is

running, the engine should be completely dismantled,

and a new big end assembly fitted.

Dismantling for decarbonising and piston inspection as described so far is carried

out without removing the engine from the frame. Assembly from this point is

described on Page 18.

REMOVING ENGINE FROM THE FRAME AND

COMPLETE DISMANTLING

The procedure for the removal of the engine from the

frame and dismantling will be described from the

point reached in the previous section when the

cylinder head and barrel have been removed. The oil

pipes must next be disconnected, but first the oil tank

should be drained. Alternatively the pipes can be

disconnected and suitably plugged.

Detach the leads to the dynamo (both of which are

held by a small plate and one screw), and then the

earth wire adjacent to the contact breaker housing.

Follow these with the sparking plug lead.

The magneto control cable can be readily detached

from the handlebar lever.

REMOVING CHAINCASE

The oil bath chaincase follows next. Take off the

footrest and then undo all the screws round the rim of

the chaincase. The nuts of these screws are welded

to the other half of the case and so cannot be lost.

When the outer chaincase cover is taken off, careful

note should be made of the positioning of the cork

washers and distance pieces, to facilitate

replacement. Before removing the chain loosen

clutch as described in next paragraph, and then

dismantle engine shaft cush drive. Tap the lock

washer clear of the slot in the cush drive retaining nut

and

12

Loading...

Loading...