A (7) Resistor and Immobiliser

Check for cracks in the insulation and for positive

contacts of the high tension cable; always disconnect

lead at sparking plug before unscrewing

immobilisers.

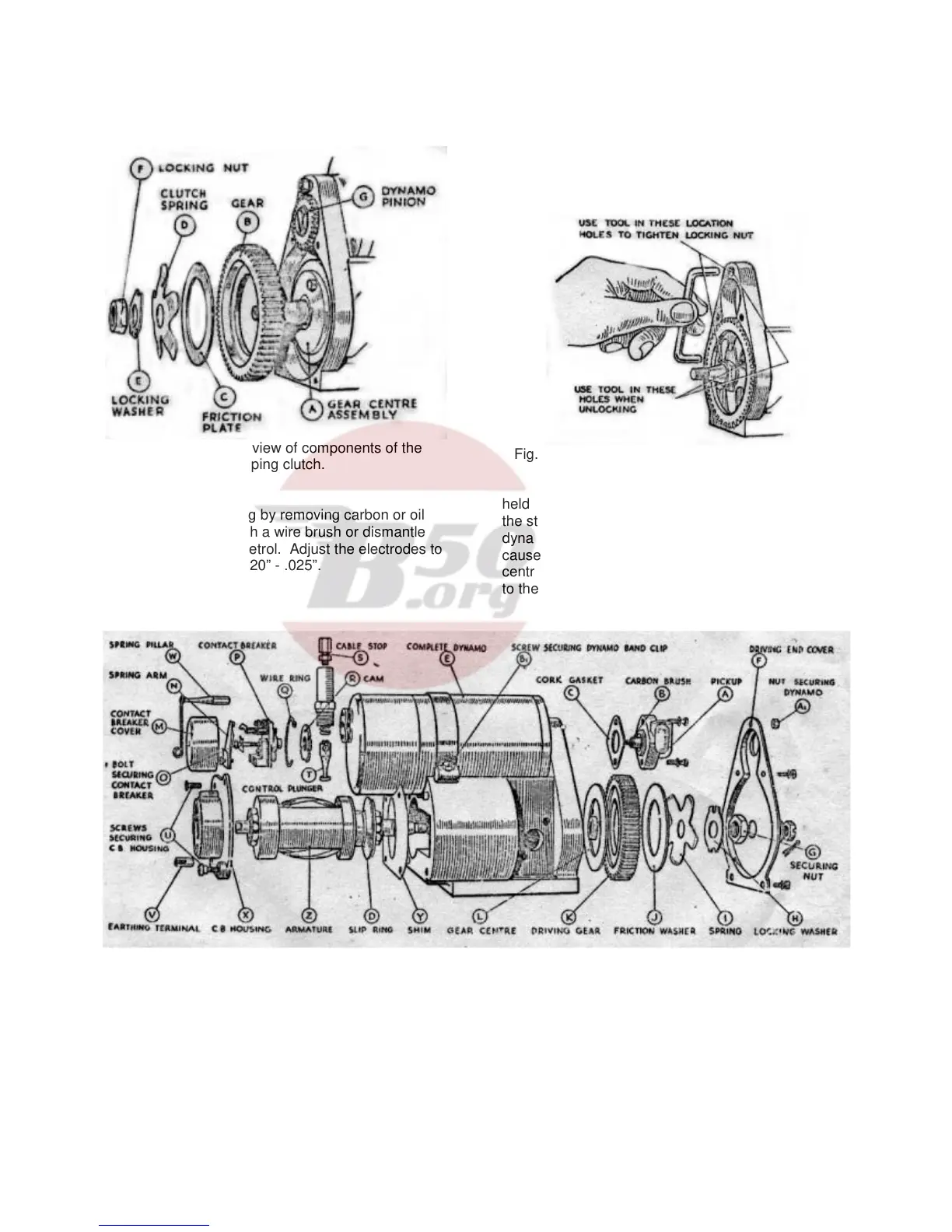

Fig. 49. Exploded view of components of the

Slipping clutch.

A (8) Sparking Plug.

Clean the sparking plug by removing carbon or oil

from the electrodes with a wire brush or dismantle

the plug and wash in petrol. Adjust the electrodes to

give a gap setting of .020” - .025”.

A (9) Magneto Slipping Clutch (see Fig. 49).

Description

A shock absorbing drive is incorporated in the larger

of the two gears, which take the drive from the

magneto shaft to the dynamo. This considerably

relieves the peak loading on the teeth of the driving

gear and gives a far longer life. The drive is taken

from the gear centre (A), which is keyed to the

magneto shaft, through the fabric gear (B), which is

Fig. 50. Slipping clutch showing the jig to lock the

large gear.

held against the gear centre under the pressure of

the star shaped spring (D) to the pinion (G) on the

dynamo shaft. The effect of a violent overload is to

cause the fabric gear to slip relative to the gear

centre and so prevents shock from being transmitted

to the fabric gear.

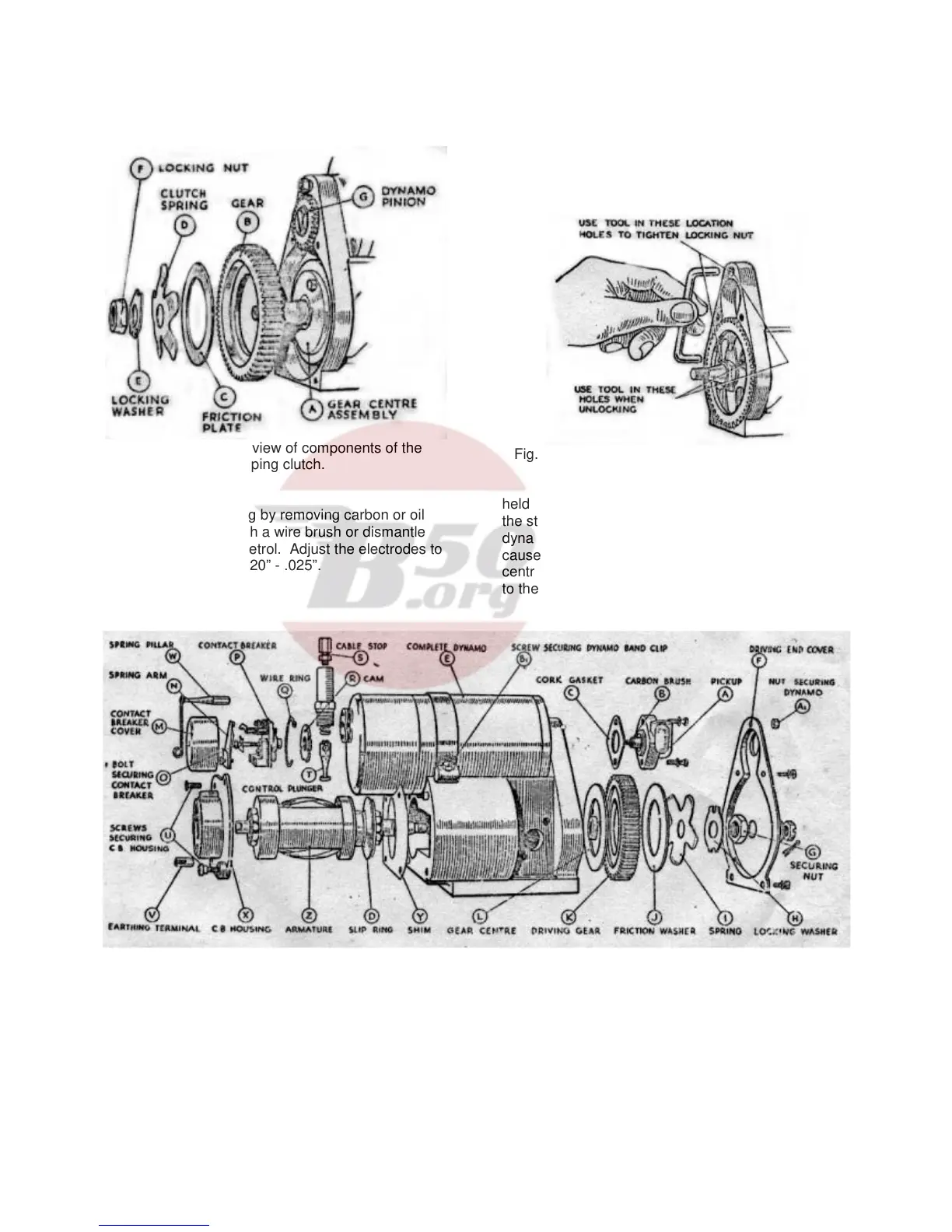

Fig. 51. Exploded view of magneto portion of dynamo.

35

Loading...

Loading...