24

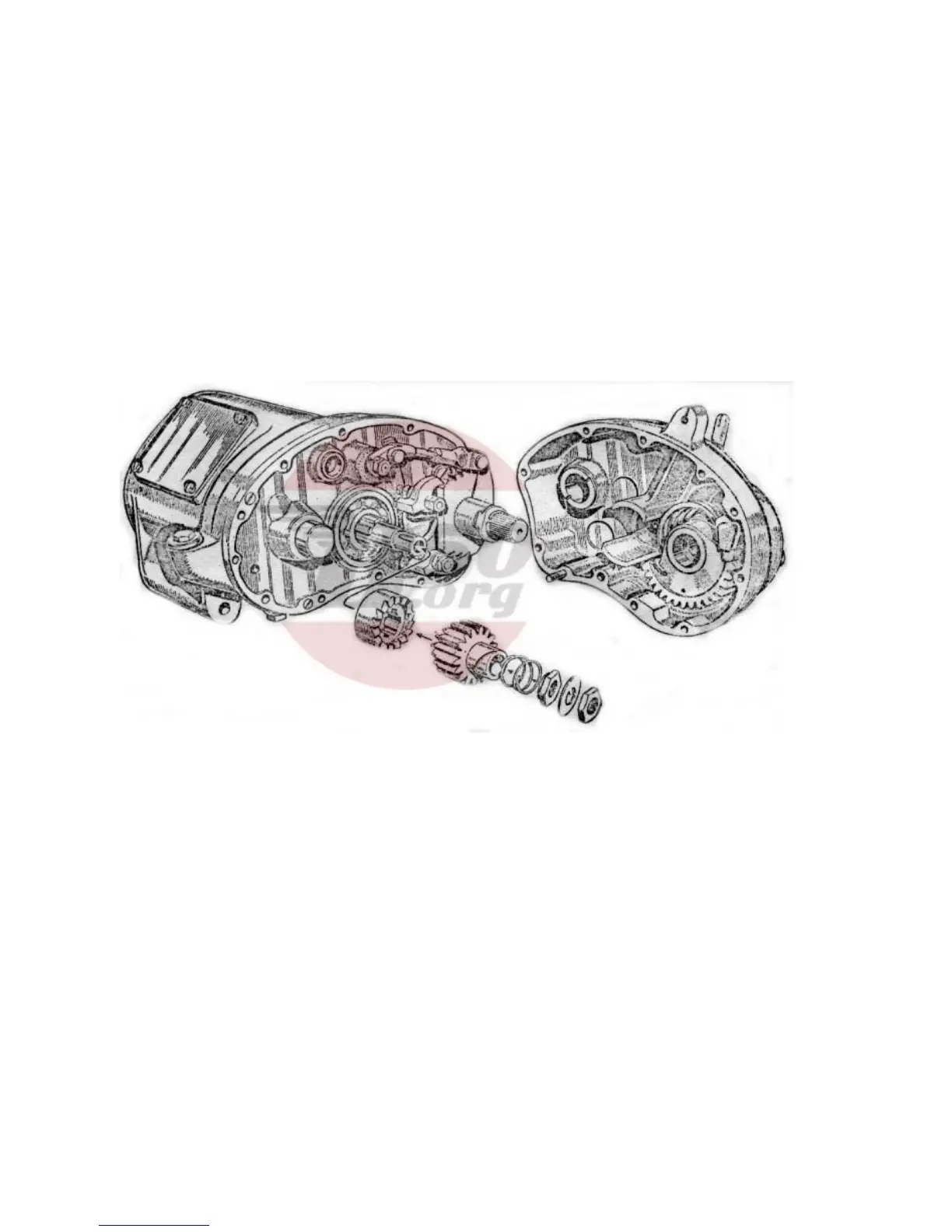

It is only possible to refit the shafts and their pinions

in the box provided that the shafts are first

assembled (with pinions in top gear position) outside

the gearbox and then all fitted together.

Commencing with the layshaft, take off the low gear

pinion only (this is the largest on the shaft) and hold

the shaft in the left hand with the drilled end towards

the wrist. Take up the selector shaft and fit the fork

nearest to the small pinion into the dog clutch on the

layshaft. Pick up the mainshaft, which should be

complete with its dog clutch, and put it in position so

that the second selector fork engages with the

mainshaft dog clutch. The whole assembly can now

be fitted into the gearbox, the mainshaft being the

first to enter its bearing. Verify again through the

inspection cover that the pinions are set in the top

gear position (see Fig. 35). In this position the dog

clutch on the mainshaft is in mesh with the pinion

sleeve.

Replace the low gear pinion on the layshaft and if all

has been assembled correctly, the face of this pinion

should

be just flush with its mating pinion on the

mainshaft. The oil flinger washer and spacing collar

can now be refitted to the mainshaft (see Fig. 35).

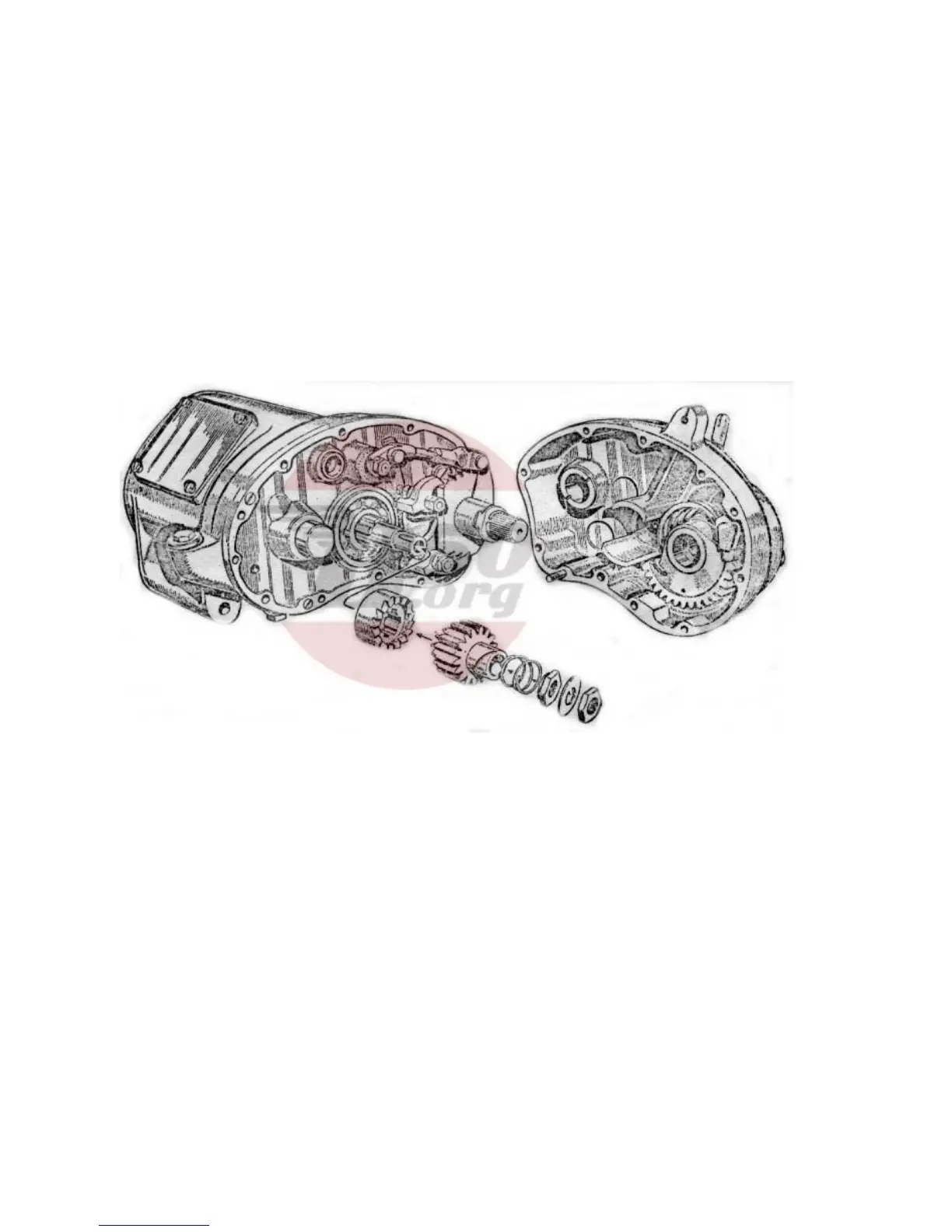

The inner cover is next to be assembled. Set the

selector quadrant in the top gear position (see Fig.

36) and replace the cover. The paper washer

between the inner cover and the gearbox shell

should be smeared with jointing compound before

final assembly. If the cover will not fit properly at the

first attempt, a slight

movement of the selector, by

means of a spanner, will cause the selector teeth to

mesh properly with the selector shaft pinion and then

the cover may be pressed home.

Replace the four screws and locking strip, bending

the corners of the latter to suit. All shafts should

have the minimum of end play, and engagement of

dogs should be checked in each gear.

The ratchet mechanism may now be refitted to the

mainshaft, the parts assembling in the following

order: Ratchet, bush, ratchet pinion, spring and

shouldered nut. The latter should be tightened by

finger pressure only. Replace the lockwasher and

note that the tongue in this washer engages with the

groove machined in the mainshaft. Screw up the

locknut very tightly, and tap the edge of the washer

over the nut.

RE-ASSEMBLY OF THE GEARCHANGE

The ratchet sleeve plate (i.e., the plate in which there

are a series of teeth) should be held in the left hand

with the shortest diameter of the sleeve uppermost

(see Fig. 38). One of the pawl carrier plates will be

seen to have thin washer welded on to both faces,

and this plate should now be superimposed upon the

ratchet plate so that the pawl fits into one of the teeth

adjacent to the link pin hole. Place the remaining

pawl carrier on top of the original one so that it’s pawl

engages with the second set of teeth on the ratchet

plate.

Still holding the gearchange assembly in the left

hand, take up the gearchange spindle in the right

hand, holding it by the threaded end and fit it into the

ratchet sleeve so that the plate fixed to the spindle

lies between the spring anchor pegs. With the aid of

a pair of pliers, replace the two springs and fit the

circlip in position. The whole process of re-assembly

of the gearchange mechanism will be made much

easier by a study of the illustration (Fig. 38).

The unit is now ready for re-assembly into the

gearbox. Make sure that the spring-loaded plunger is

in position behind the unit before it is replaced.

Couple the link arm to the ratchet plate and take care

to replace the split pin. It should not be necessary to

make any adjustment to the length of the link itself –

this has been set when the gearbox was originally

built, but if the gears will not engage properly a slight

adjustment to the length of the link will be sufficient.

Loading...

Loading...