Next, remove the pin from the link rod between the

selector quadrant and the gearchange mechanism at

the latter end and unscrew the nut off the end of the

gearchange spindle. The gearchange mechanism

can now be taken out as a complete unit, and

dismantled later. Take care not to lose the small

plunger and spring exposed by the removal of the

previous parts.

The ratchet mechanism on the mainshaft must be

dismantled next. First unscrew the locknut,

straighten the tag washer, and remove it. By

unscrewing the next nut, all the remaining parts of

the ratchet mechanism will be free and can be taken

off.

There is now no obstacle to the removal of the

gearbox inner cover except for its fixing screws of

which there are four. Two of these are fixed by a

locking strip and the ends of this must be

straightened before the screws can be removed. As

the cover comes off, it will contain the mainshaft

ballrace, and leave exposed loosely on the mainshaft

an oil flinger (thin) and spacing collar (thick).

Also assembled on the inner cover is the gear

selector quadrant, but here again this need not be

disturbed unless attention is obviously required. If it

has to be removed, take care not to lose the plunger

and spring and make sure they are re-fitted when

assembling.

If, when the inner cover is withdrawn, the three shafts

(main, lay and selector) also come out still

assembled in the cover, they may be quite easily

detached, as they are a running fit in their bushes. In

the same way if the shafts are still in the box, after

removing the gearbox cover, they can be withdrawn

with similar ease by removing all the shafts together.

The layshaft bushes are, of course, a press fit in the

gearbox and, if necessary, must be driven out with

the aid of a soft punch (

15

/

16

Examine the various parts for wear and if the forks,

which actuate the sliding dogs, show signs of seizure

it is advisable to replace them. Attempts to erase the

seizure marks will result in excessive side play.

Replacement sliding dogs may be found

to have convex faces on the dogs but

this will not affect interchange ability, if

the originals had flat faces.

” diameter).

The top gear pinion sleeve is now the only part still

left in the gearbox, and if the sprocket locknut is

unscrewed, after suitable attention to the tag washer,

the socket may be removed and the pinion tapped

into the gearbox with the aid of a wooden mallet. If

difficulty is experienced in holding the pinion whilst

the sprocket in unscrewed, a fixture similar to that in

Fig. 34 will solve the problem.

Do not disturb the ballrace unless it is suspected of

being faulty. Wash it thoroughly in paraffin, to

remove all traces of oil, when any play will be

immediately detected.

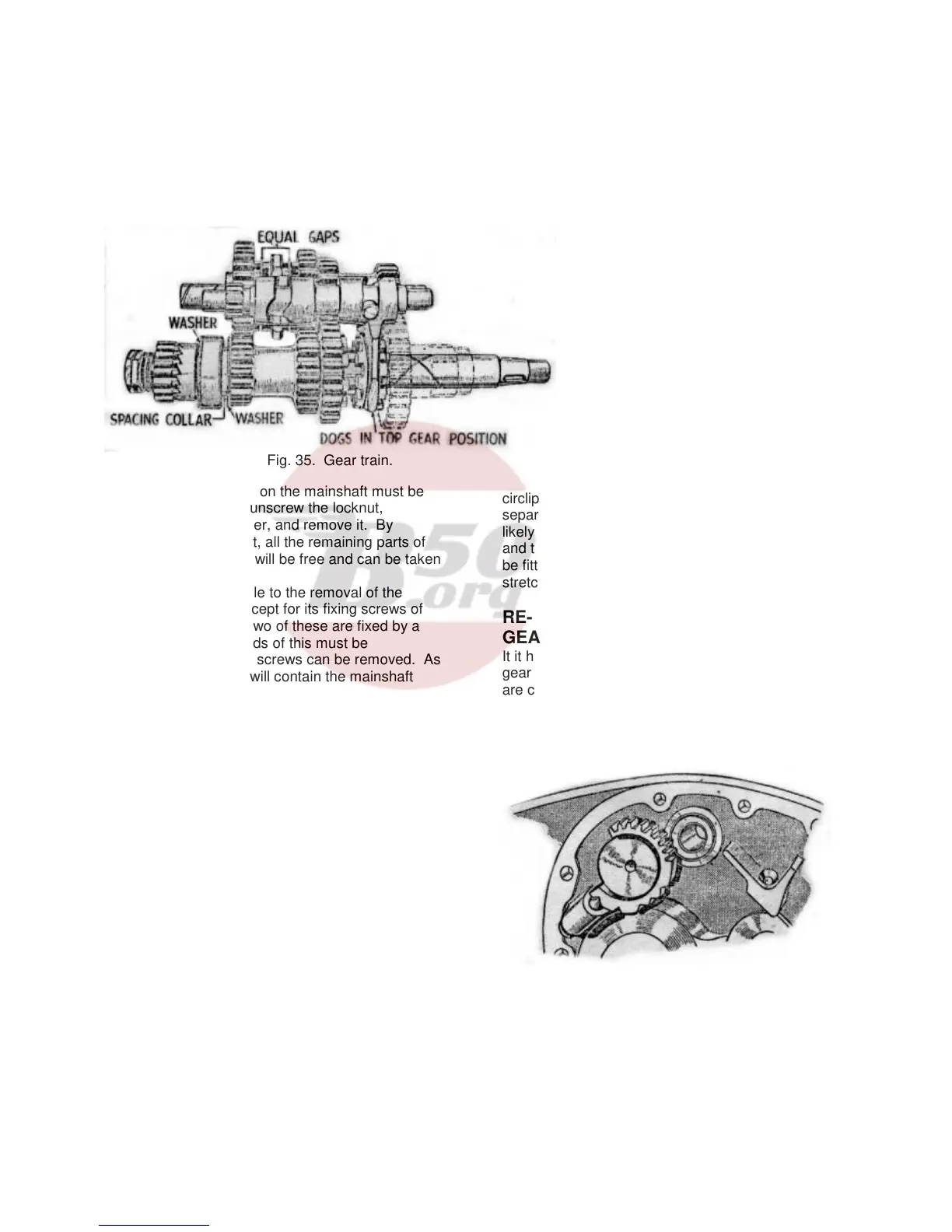

Loose pinions on the lay and mainshafts

may be rebushed if required, and of

course, pinions with damaged teeth

should also be replaced.

Fixed pins on the layshaft and mainshaft

are pressed on and new components

must be a tight fit.

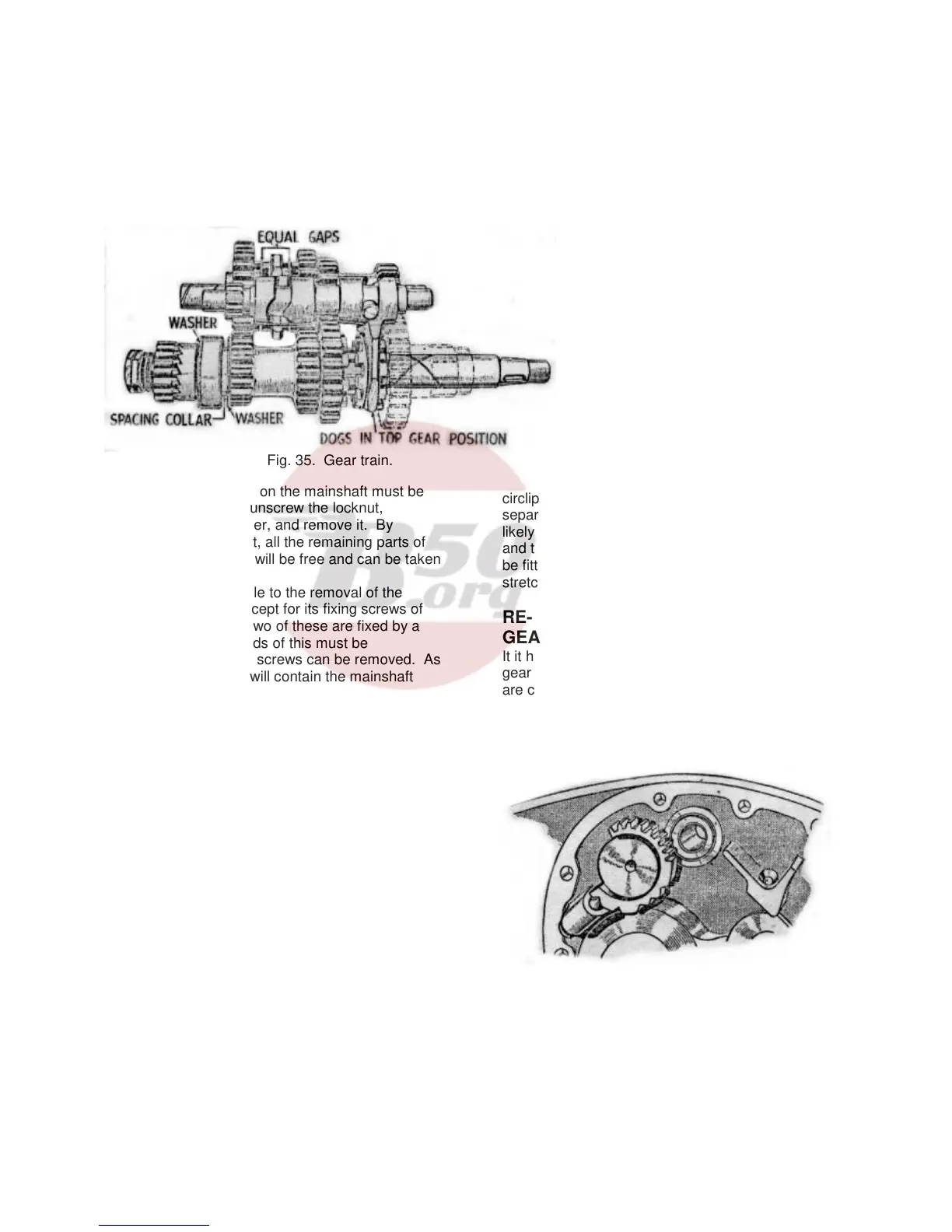

DISMANTLING THE

GEARCHANGE MECHANISM

It is only necessary to prise the two pawl

springs off their pegs, and to remove the

circlip, when the whole unit can be stripped into

separate components. The only parts which are

likely to show signs of excessive wear are the pawls

and the ratchet plate, and new components should

be fitted if required. If the pawl springs show signs of

stretching, they too, should be replaced.

RE-ASSEMBLY OF THE GEARBOX AND

GEARCHANGE MECHANISM.

It it has been decided to fit a new ballrace to the top

gear pinion, make sure that the oil flinger washers

are correctly positioned. In order to remove the

ballrace easily, warm the gearbox in boiling water.

The flat washer should be placed between the pinion

teeth and the bearing while the remaining washer fits

on the opposite side of the bearing with its depressed

f

Fig. 36. Selector quadrant

face against the bearing. If the sprocket teeth are

worn hook shaped s new one must be fitted,

otherwise rapid chain wear will result. Do not forget

to set the lockwasher into the grooves machined in

the locknut after the latter has been tightened up.

The tabs in the centre of the locknut washer must fit

properly into the sprocket splines.

Loading...

Loading...