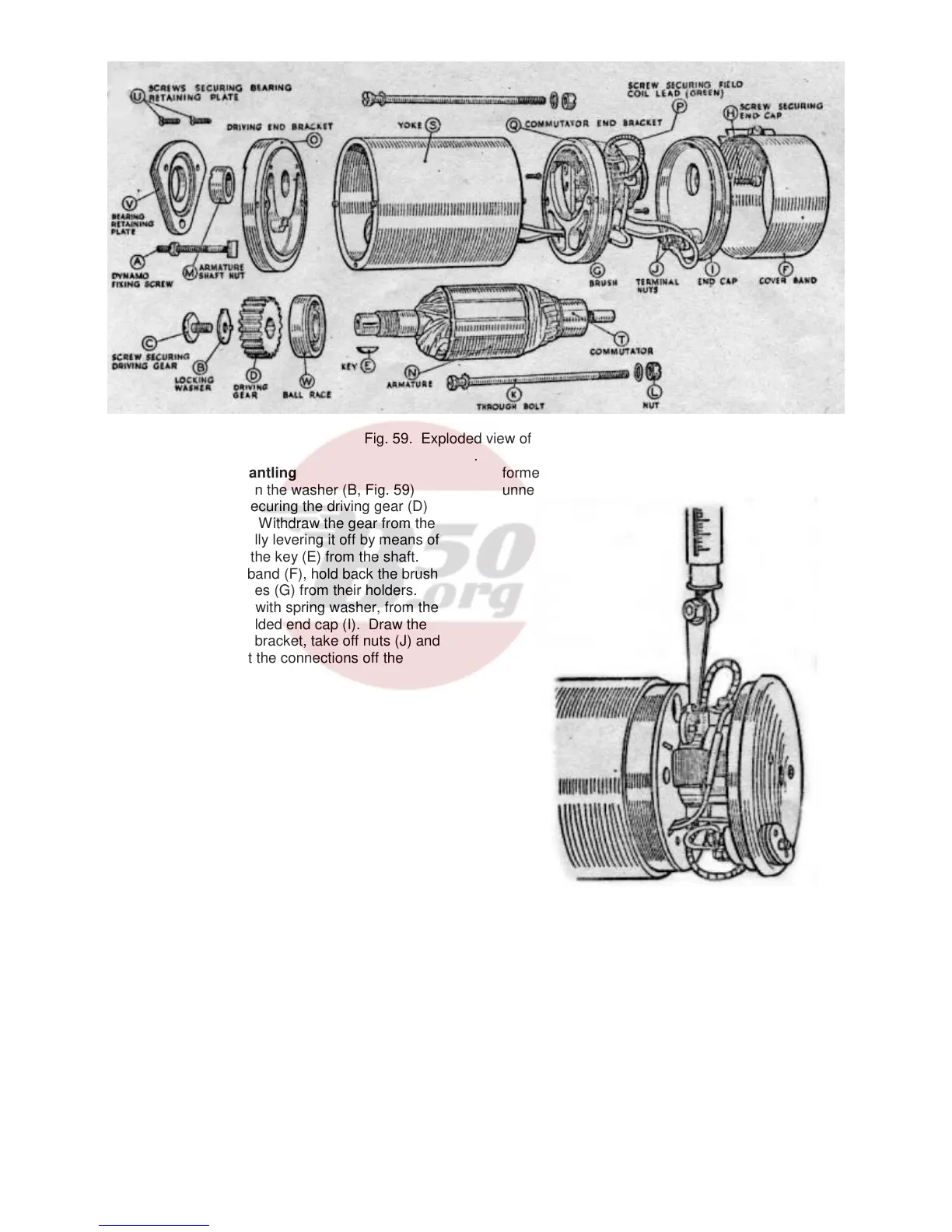

Fig. 59. Exploded view of dynamo

.

B (3) Dynamo – Dismantling

(a) Bend back the tag on the washer (B, Fig. 59)

locking the screw (C) securing the driving gear (D)

and remove the screw. Withdraw the gear from the

dynamo shaft by carefully levering it off by means of

an extractor. Remove the key (E) from the shaft.

(b) Remove the cover band (F), hold back the brush

spring and lift the brushes (G) from their holders.

(c) Take the screw (H), with spring washer, from the

centre of the black moulded end cap (I). Draw the

cap away from the end bracket, take off nuts (J) and

spring washers, and lift the connections off the

terminals.

(d) Unscrew and remove from the driving end

bracket, the two bolts (K) securing the driving end

bracket (O) and commutator end bracket (Q) to the

dynamo yoke (S). Hold the nuts (L) at the

commutator end whilst unscrewing the bolts, and

take care not to lose the nuts.

(e) Draw the armature (N) complete with end bracket

(O) out of the yoke.

(f) Unscrew the nut (M) from the driving end of the

dynamo shaft and remove the armature from the end

bracket, using a hide or wooden mallet.

(g) Take out the screw (P0 securing the green field

coil lead with the yellow sleeve to commutator end

bracket and remove the end bracket (O), withdrawing

the connectors through the slot in the insulating plate.

B (4) Dynamo Brushes.

Test if brushes are sticking. Clean with petrol and if

necessary ease the sides by lightly polishing on a

smooth file. Replace brushes in their original

positions.

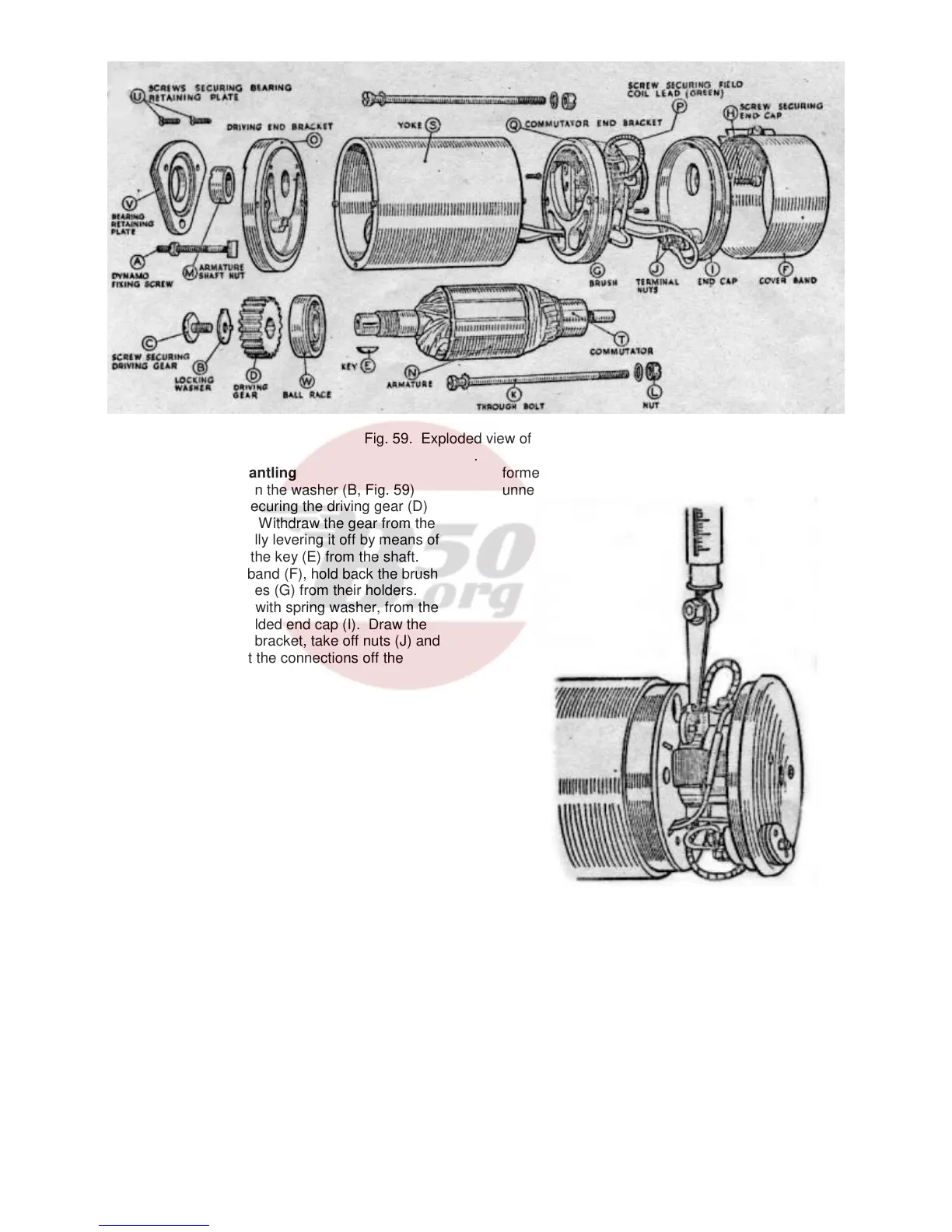

Test the brush springs with a spring scale (Fig. 60) if

available. The correct tension is 10-15ozs.

Fit a new spring if tension is low. If the brushes are

worn so that the flexible is exposed on the running

face, new brushes must be fitted. Brushes are pre-

formed so that bedding to the commutator is

unnecessary.

Fig. 60. Method of measuring brush spring tension.

Dynamo - Commutator

A commutator in good condition will be smooth and

free from pits or burned spots. Clean the

commutator with a petrol moistened cloth. If this is

ineffective, carefully polish with a strip of very fine

glass paper while rotating the armature. To remedy

a badly worn commutator, mount the armature with

or without the drive end bracket in a lathe, rotate at

high speed and take a light cut with a very sharp tool.

Do not remove more metal than is necessary. Polish

the commutator with very fine glass paper.

39

Loading...

Loading...