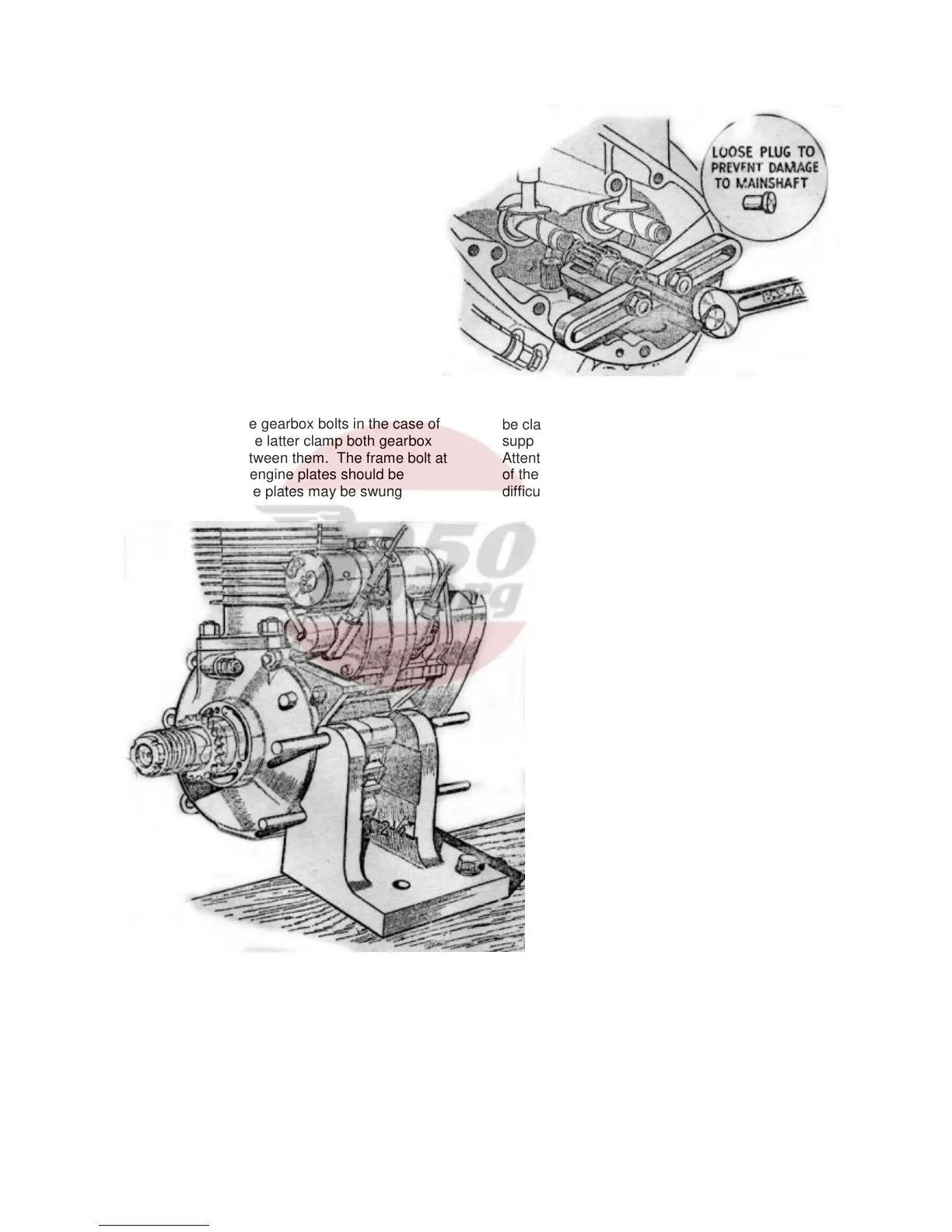

Fig. 16 Engine Shaft pinion extractor

unscrew the latter. Then withdraw the spring and

cam sleeve, leaving the sprocket and chain in

position. Next, take off the clutch.

REMOVING CLUTCH.

This can be accomplished with the aid of an

extractor (shown in Fig. 30) after removal of the

clutch outer cover, the actuating cap and the

central sleeve nut. The extractor screws into

the thread provided inside the clutch centre.

Now uncouple the chain, the spring link being of

the usual “hairpin” type. Take off the clutch as a

unit and then the cush drive. There now

remains the inner half of the chaincase, which is

held to the crankcase by three bolts, wired

together for locking purposes, and by a nut

attaching the rear chainguard to the case. The

nut can be released easily after the chaincase is

pulled off the crankcase register.

The bolts holding the crankcase to the front and

rear engine plates can now be removed and it is

advisable to release the gearbox bolts in the case of

the rear plates, since the latter clamp both gearbox

and crankcase lugs between them. The frame bolt at

the bottom of the front engine plates should be

slackened off so that the plates may be swung

forward, greatly facilitating removal of the engine.

DISMANTLING THE ENGINE

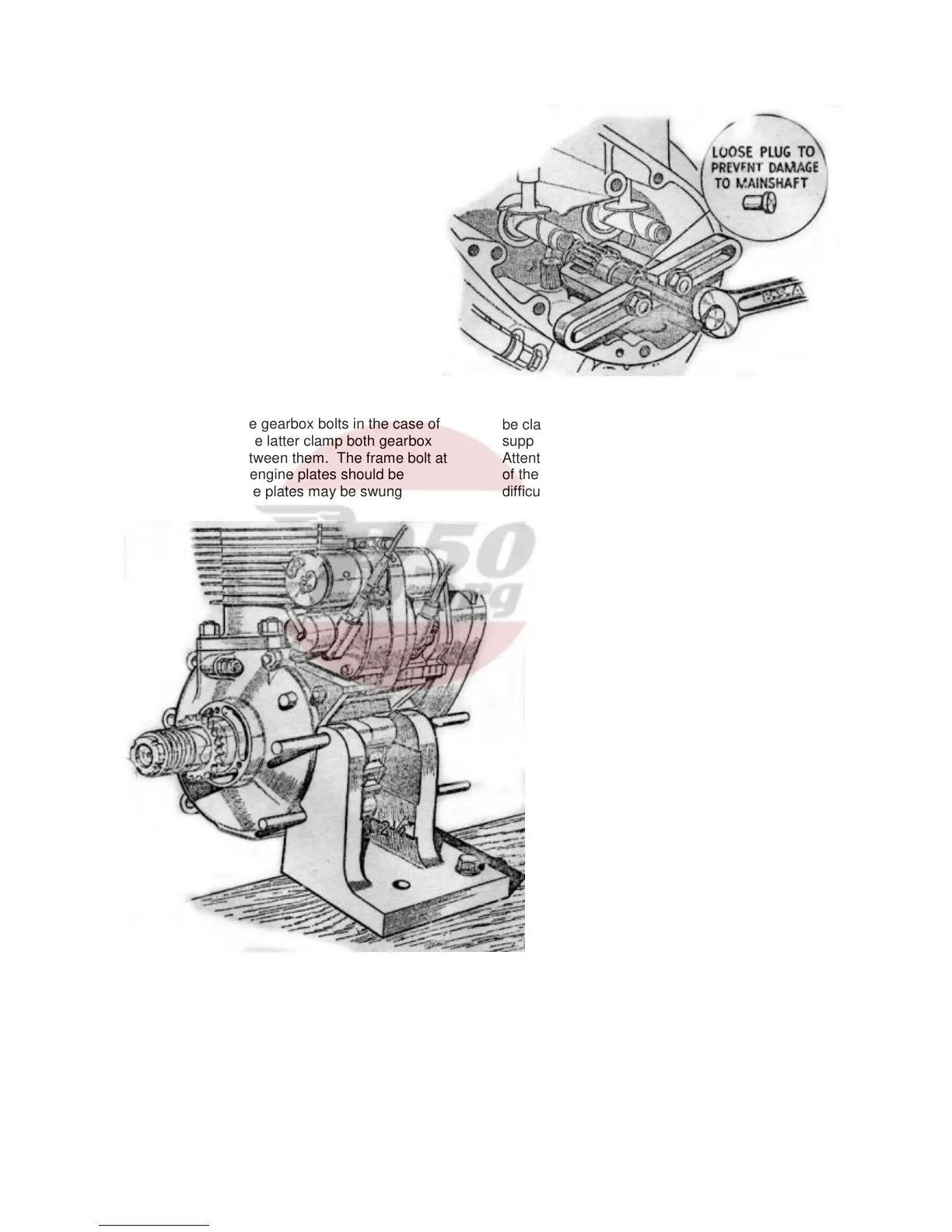

It is advisable before commencing to dismantle the

engine to construct a simple fixture such as that

shown in Fig. 15 on which the engine can be

mounted. Alternatively, a lug on the crankcase may

be clamped in a vice and the crankcase itself

supported on the bench.

Attention may next be given to the crankcase portion

of the engine. Take off the timing cover, and if any

difficulty is experienced in releasing the screws, if will

facilitate matters if a long screwdriver is

used, and the head given a sharp tap with a

mallet. On some models an oil tell-tale is

fitted on the timing cover and this must also

be taken off. It is possible that the jointing

compound on the case between the cover

and crankcase will not allow the cover to be

removed easily and in this event, the lugs on

the end of the cover should be used to tap it

off. Take care not to damage the small

nozzle in the timing cover which feeds oil to

the hollow crankshaft; if it should be refitted

in a bent condition it will foul the mainshaft,

and break off eventually, thus starving the

big end and piston of oil.

REMOVING MAGDYNO PINION

Next, the magdyno pinion should be

removed. Since the pinion fits on to a taper

shaft difficulty may be experienced in

removing it. It is not advisable to attempt to

prise the pinion off with levers, as there is a

grave risk of breaking the timing case, but it

will come off quite simply provided an

extractor to that shewn in Fig. 10 is used.

Note that there is a special oil seal fitted in

the timing case, behind the magneto pinion.

It is only necessary to release the magdyno

strap bolt, when the straps can be swung on

one side, and the magdyno lifted off. The latter is

located by dowels only, and if any shims were fitted

below the magdyno they should be carefully

preserved.

13

Loading...

Loading...