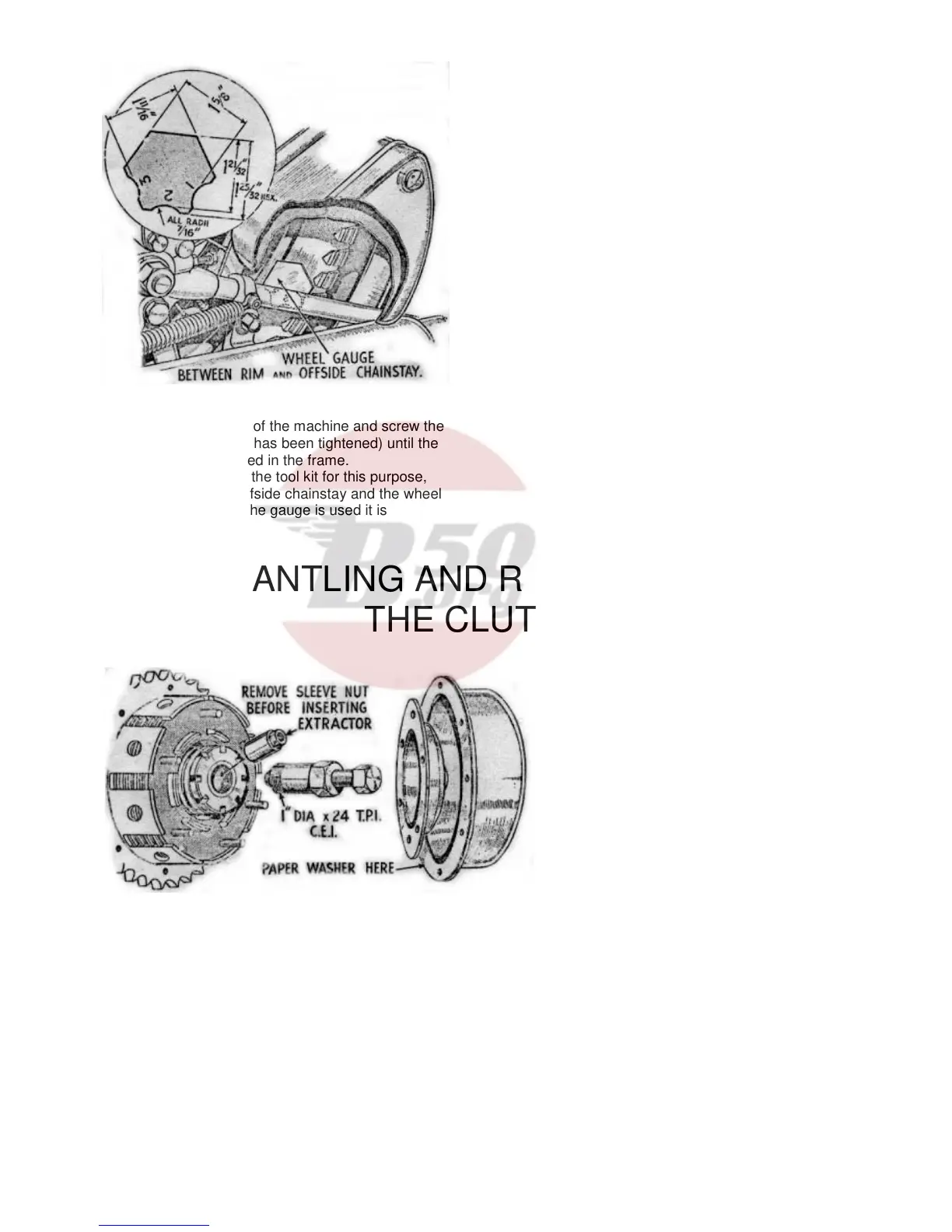

Fig. 30. Clutch extractor tool.

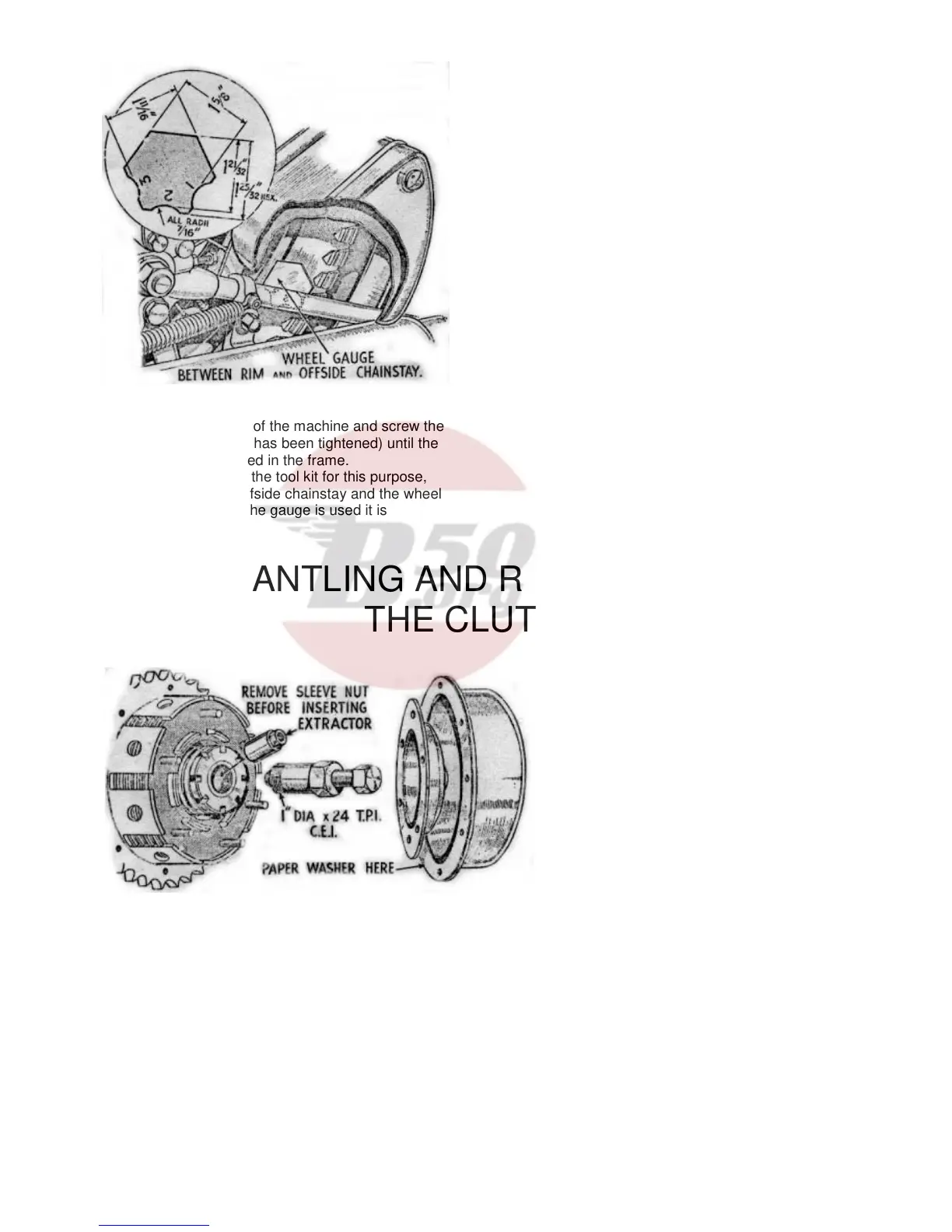

Fig. 29. Wheel alignment gauge.

Now turn to the offside of the machine and screw the

adjuster in (if the chain has been tightened) until the

wheel is properly aligned in the frame.

A gauge is provided in the tool kit for this purpose,

and fits between the offside chainstay and the wheel

rim (Fig. 29). (Before the gauge is used it is

necessary that the wheel alignment be checked with

a straight edge and the see which gauge – 1, 2 or 3 –

is the correct fit). If the machine is in the workshops,

however, it is much better to use a wooden straight

edge, in the normal manner, i.e., it should touch each

wheel in two places. Tighten the cam locknut and

check the chain setting. If correct, tighten the offside

spindle nut and then the offside adjuster locknut.

NOTE: It may be necessary to adjust the rear brake,

since this will have been altered by movement of the

rear wheel.

DISMANTLING AND RE-ASSEMBLING

THE CLUTCH

Take off the left footrest and then undo all the screws

around the rim of the chaincase. The nuts of these

screws are welded to the other half of the case, and

so cannot get lost. As the outer chaincase cover is

taken off, careful note should be made of the

repositioning of the washers, etc., for replacement

purposes (see Fig. 25). The joint washer should be

carefully preserved.

The clutch is next to be removed exposing the clutch

pressure plate, which in turn can be taken off after

removal of the six nuts. By unscrewing the

central ring nut all the clutch plates, both

steel and fabric, will be released. Take care

that the spring does not fly off as the nut is

removed.

The clutch hub is held to the gearbox

mainshaft by means of a sleeve nut through

which the clutch push rod will be seen to

protrude. Unscrew this nut and apply the

extractor as shown in Fig. 30, thus drawing

the remainder of the clutch off the

mainshaft.

The various parts may now be examined for

wear. Special attention should be paid to

the slots in which the steel plates slide and if

any grooves worn in them are not too deep

the sides of the slots can be filed smooth. If the

sprocket teeth are worn to a hook shape the sprocket

must be replaced, otherwise rapid chain wear will

result. The steel plates should be smooth and if they

are badly scored should be replaced, while the fabric

rings will require a thorough washing in petrol if there

is any trace of oil on them. Finally, examine the

rollers and tracks and verify that the cork washer is

intact.

21

Loading...

Loading...