6-2T -296

5. Front seat both manifold gauge set valves and dis-

connect from cylinder . The gauge set is now ready

for use.

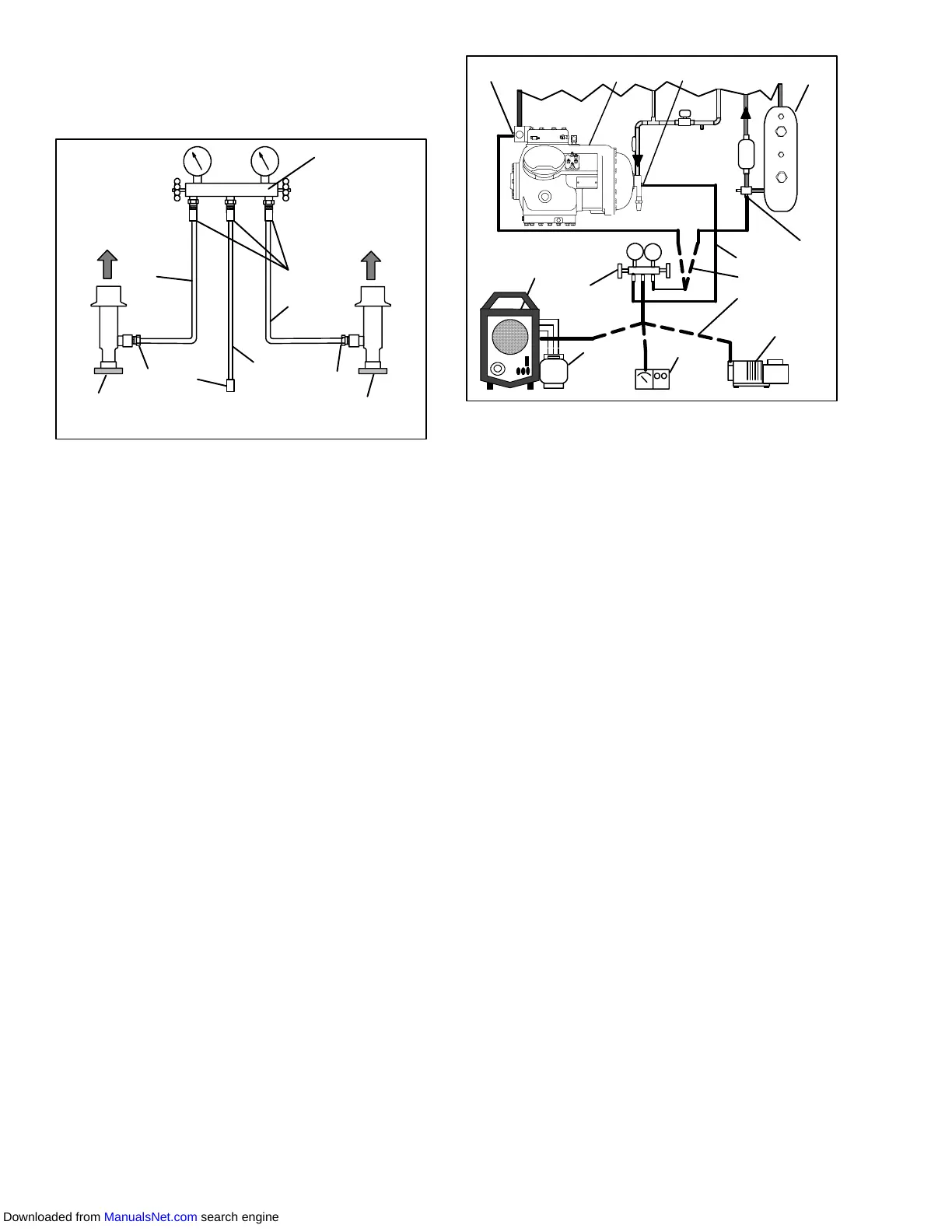

To Low Side

Service Port

To High Side

Service Port

-Red

- Yellow

Blue

Red Knob

Blue Knob

1

2

3

3

3

2

4

5

6

4

1. Manifold Gauge Set

2. Hose Fitting (0.5-16 Acme)

3. Refrigeration and/or Evacuation Hose

. (SAE J2196/R-134a)

4. Hose Fitting w/O-ring (M14 x 1.5)

5. High Side Field Service Coupling

6. Low Side Field Service Coupling

Figure 6-3 R-134a Manifold Gauge/Hose Set

b. Connecting Manifold Gauge/Hose Set

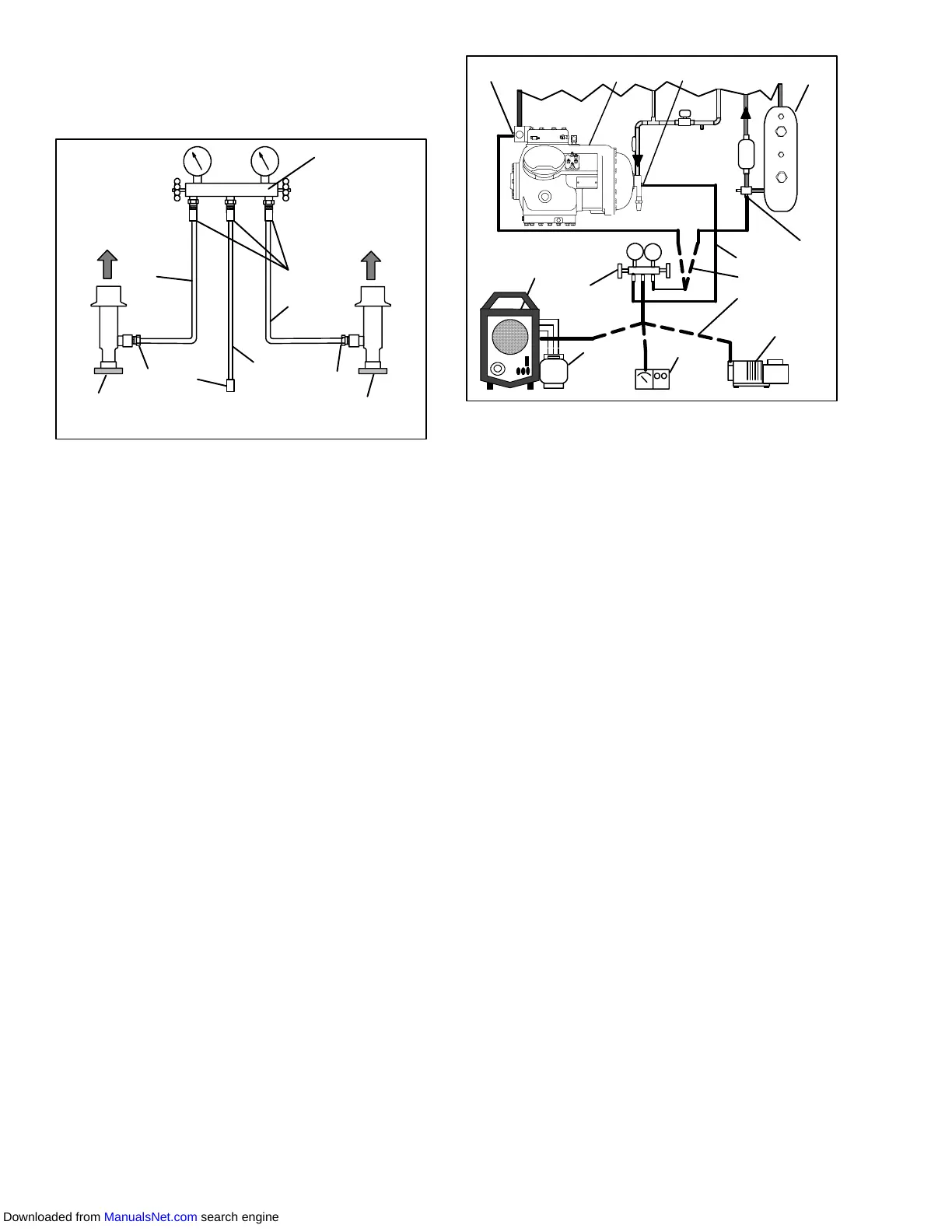

Connection of the manifold gauge/hose set (see

Figure 6-4) is dependent on the component being

serviced. If only the compressor is being serviced, the

highsidecouplingis connectedtothe dischargeservice

valve. Forserviceof the lowside(after pumpdown),the

high side coupling is connected to the liquid line service

valve. The center hose connection is brought to the tool

beingused. Toconnectthemanifoldgauge/hoseset,do

the following.

1. Remove servicevalve stem caps andcheck tomake

sure they are backseated. Remove service port

caps. (See Figure 6-1)

2. Connect the high side field service coupling (see

Figure 6-3) to the discharge or liquid line valve ser-

vice valve port.

3. Turn the high side field service coupling knob (red)

clockwise, which will open the high side of the sys-

tem to the gauge set.

4. Connect the low side field service coupling to the

suction service valve port.

5. Turn the low side field service coupling knob (blue)

clockwise,whichwillopenthelowsideof thesystem

to the gauge set.

6. To read system pressures: slightly midseat the high

side and suction service valves.

6

4

5

7-BLUE

D

S

10

1

2

3

8-YELLOW

9-RED

13

11

12

1. Discharge Service

Valve

2. Compressor

3. Suction Service Valve

4. Receiver or Water

Cooled Condenser

5. Liquid Service Valve

6. Vacuum Pump

7. Low Side Hose

8. Center Hose

9. High Side Hose

10. Electronic Vacuum

Gauge

11. Manifold Gauge Set

12. Refrigerant Cylinder

13. Reclaimer

Figure 6-4. Refrigeration System Service

Connections

CAUTION

To prevent trapping liquid refrigerant in the

manifoldgaugesetbesuresetisbroughtto

suction pressure before disconnecting.

c. Removing the Manifold Gauge Set

1. While the compressor is still ON, backseat the high

side service valve.

2. Midseat both hand valves on the manifold gaugeset

and allow the pressure in the manifold gauge set to

bedrawndowntosuctionpressure. This returnsany

liquidthatmaybeinthehighsidehosetothesystem.

3. Backseat the suction service valve. Backseat both

field service couplings and frontseat both manifold

set valves. Remove the couplings from the service

ports.

4. Install both service valvestem caps and serviceport

caps (finger-tight only).

6.4 PUMPING THE UNIT DOWN

To service the filter-drier, moisture-liquid indicator,

expansion valve, suction modulation valve, quench

valve or evaporator coil, pump the refrigerant into the

high side as follows:

a. Attach manifold gauge set to compressor service

valves. Refer to paragraph 6.3.

b. Start the unit and run in a cooling mode for 10 to 15

minutes.Frontseat the liquid lineservice valve. Place

start-stopswitchintheOFFpositionwhenthesuction

reaches a positive pressure of 0.1 kg/cm@ (1.0 psig).

Downloaded from ManualsNet.com search engine

Loading...

Loading...