6-12T -296

tact occurs. Do not allow the solution to

splash onto concrete.

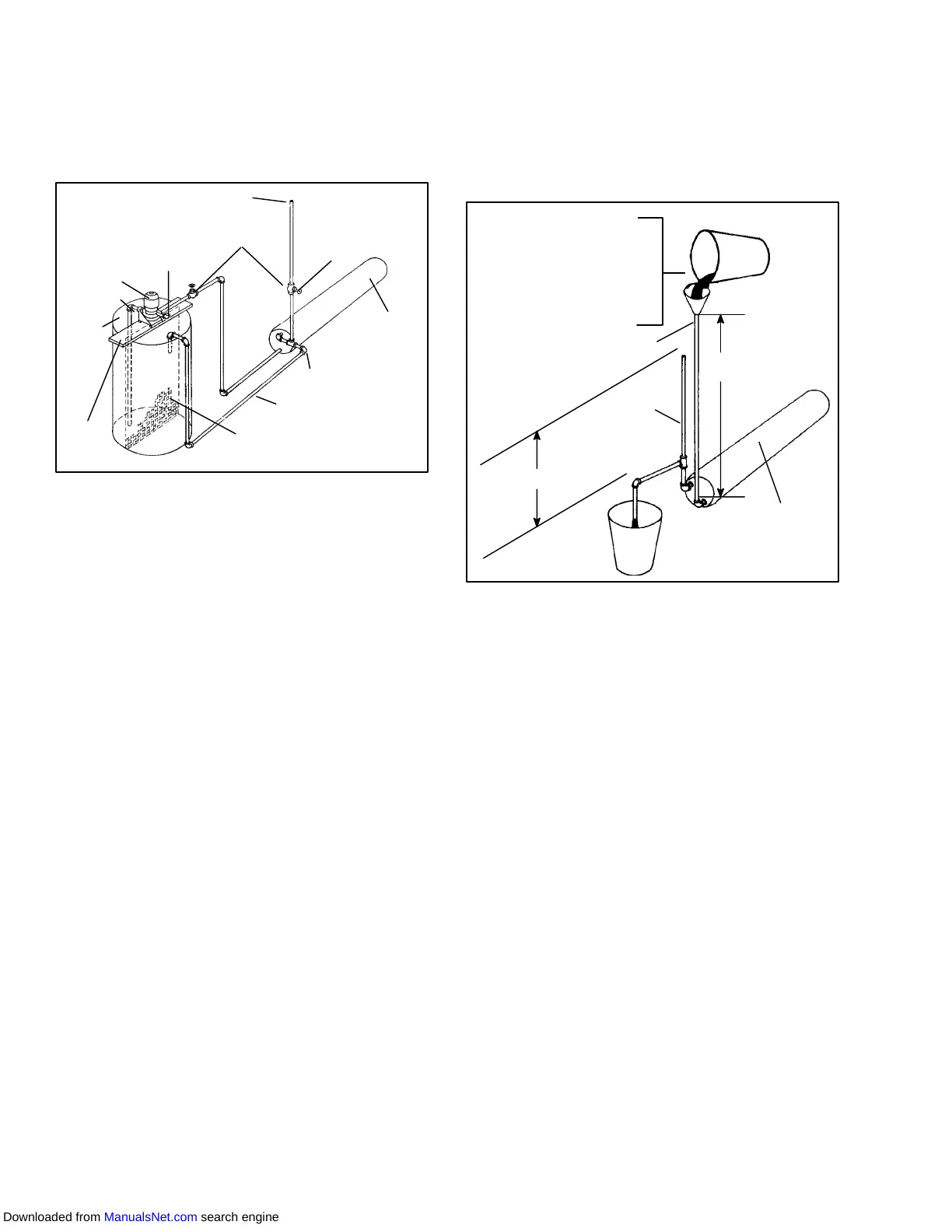

5. Fill the tubes with this solution by filling from the bot-

tom. See Figure 6-17. Important: be sure to provide

a vent at the top for escaping gas.

Centrifugal pump

30 GPM at 35’ head

Pump

Suction

Pump

support

Tank

Fine mesh

screen

Return

Remove water

regulating valve

Condenser

Globe

valves

Vent

Close vent pipe

valve when pump

is running.

Priming

connection

Figure 6-17 Water-Cooled Condenser Cleaning --

Forced Circulation

6 Allow the Oakite No. 32 solution to soak in the tube

coils for several hours, periodically pump-circulating

it with an acid-proof pump.

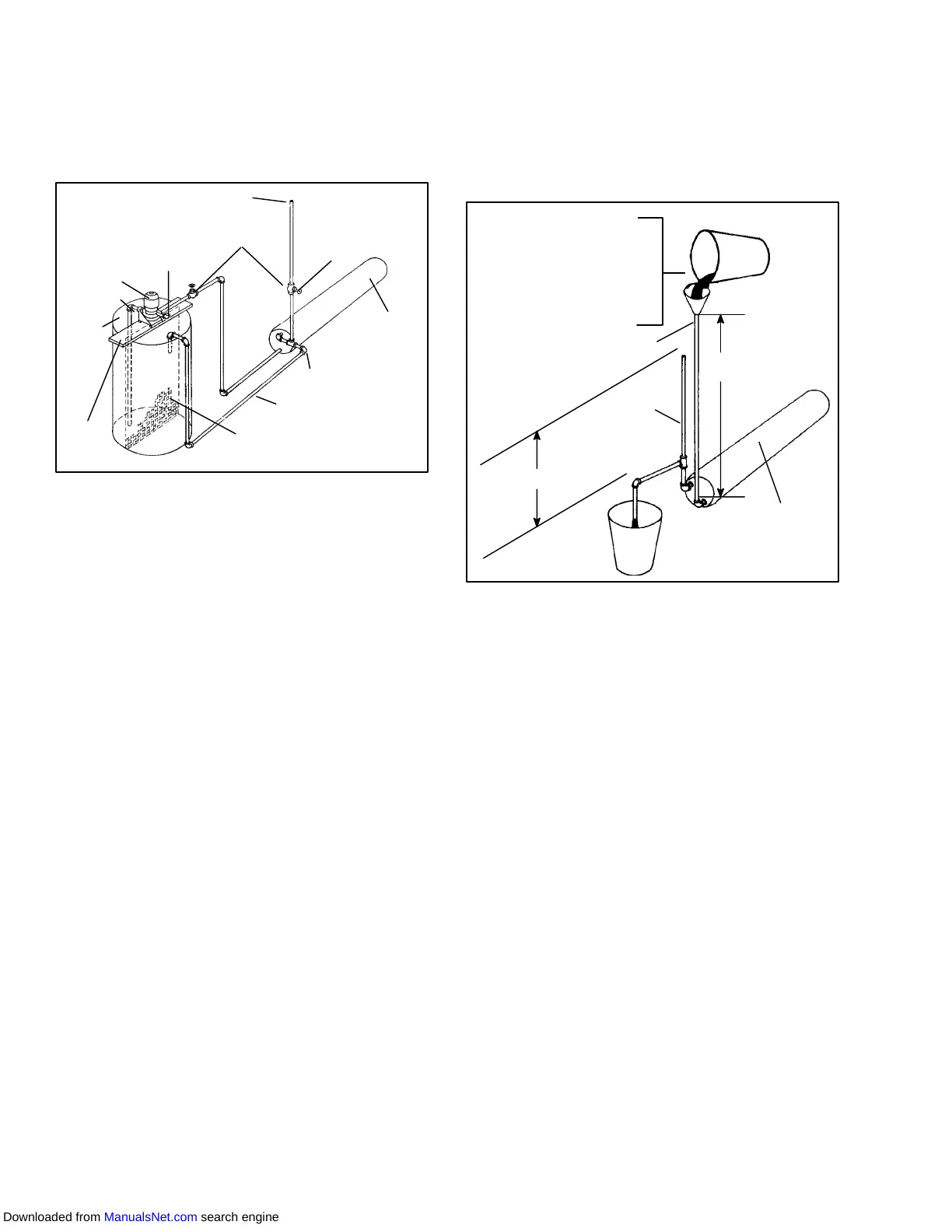

An alternate method may be used whereby a pail

(see Figure 6-18) filled with the solution and

attached to the coils by a hose can serve the same

purpose by filling and draining. The solution must

contactthescaleateverypointforthoroughde-scal-

ing. Air pockets in the solution should be avoided by

regularly opening the vent to release gas. Keep

flames away from the vent gases.

7 The time required for de-scalingwill vary, depending

upon the extent of the deposits. One way to deter-

mine when de-scaling has been completed is to

titrate the solution periodically, using titrating equip-

ment provided free by the Oakite Technical Service

representative. As scale is being dissolved, titrate

readings will indicate that the Oakite No. 32solution

is losing strength. When the reading remains

constant for a reasonable time, this is an indication

that scale has been dissolved.

8 When de-scaling is complete, drain the solution and

flush thoroughly with water.

9 Following the water flush, circulate a 56.7 gram (2

ounce) per 3.785 liter (1 U.S. gallon) solution of

Oakite No. 22 thru the tubes to neutralize. Drain this

solution.

10 Flush the tubes thoroughly with fresh water.

NOTE

If thecondenser coolingwaterisnot beingused

as drinking water or is not re-circulated in a

closedor tower system, neutralizingis not nec-

essary.

11 Put the unit back in service and operate under nor-

malload. Checktheheadpressure. Ifnormal, athor-

ough de-scaling has been achieved.

What You Can Do For Further Help:

Contact theEngineering and ServiceDepartment of the

OAKITEPRODUCTSCO.,19RectorStreet, NewYork,

NY 10006 U.S.A. for the name and address of the

service representative in your area.

Fill condenser with clean-

ing solution. Do not add

solution more rapidly than

vent can exhaust gases

caused by chemical

action.

Condenser

Vent

pipe

1” Pipe

5’ Approximate

3’ to 4’

Figure 6-18 Water Cooled Condenser Cleaning -

Gravity Circulation

6.13 FILTER-DRIER

On unitsequipped witha water-cooledcondenser, if the

sight glass appears to be flashing or bubbles are

constantly moving through the sight glass when the

suctionmodulationvalveisfullyopen, theunitmayhave

a low refrigerant charge or the filter-drier could be

partially plugged.

a. To Check Filter-Drier

1. Test for a restricted or plugged filter-drier by feeling

the liquid lineinlet andoutlet connections of thedrier

cartridge. If the outlet side feels cooler than the inlet

side, then the filter-drier should be changed.

2. Check the moisture-liquid indicator if the indicator

shows a high level of moisture, the filter-drier should

be replaced.

b. To Replace Filter-Drier

1. Pump down the unit (refer to paragraph 6.4 and

replace filter-drier.

2. Evacuate the lowside inaccordance withparagraph

6.6.

3. After unit is in operation, inspect for moisture in sys-

tem and check charge.

6.14 THERMOSTATIC EXPANSION VALVE

The thermal expansion valve (see Figure 2-2) is an

automatic device which maintains constant superheat

oftherefrigerant gas leavingthe evaporator,regardless

of suction pressure.

Downloaded from ManualsNet.com search engine

Loading...

Loading...