6-4T -296

6

45

7

DS

10

1

23

8

9

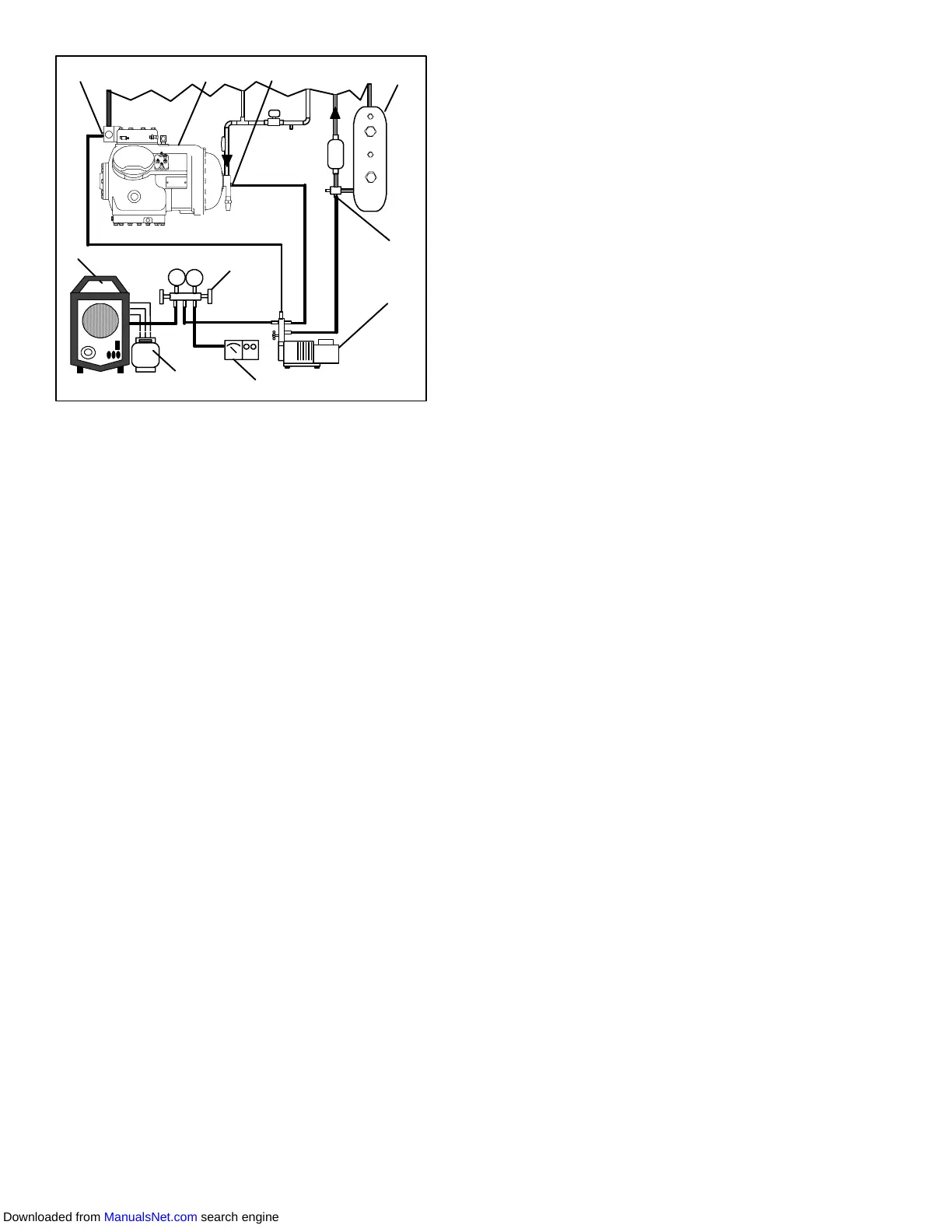

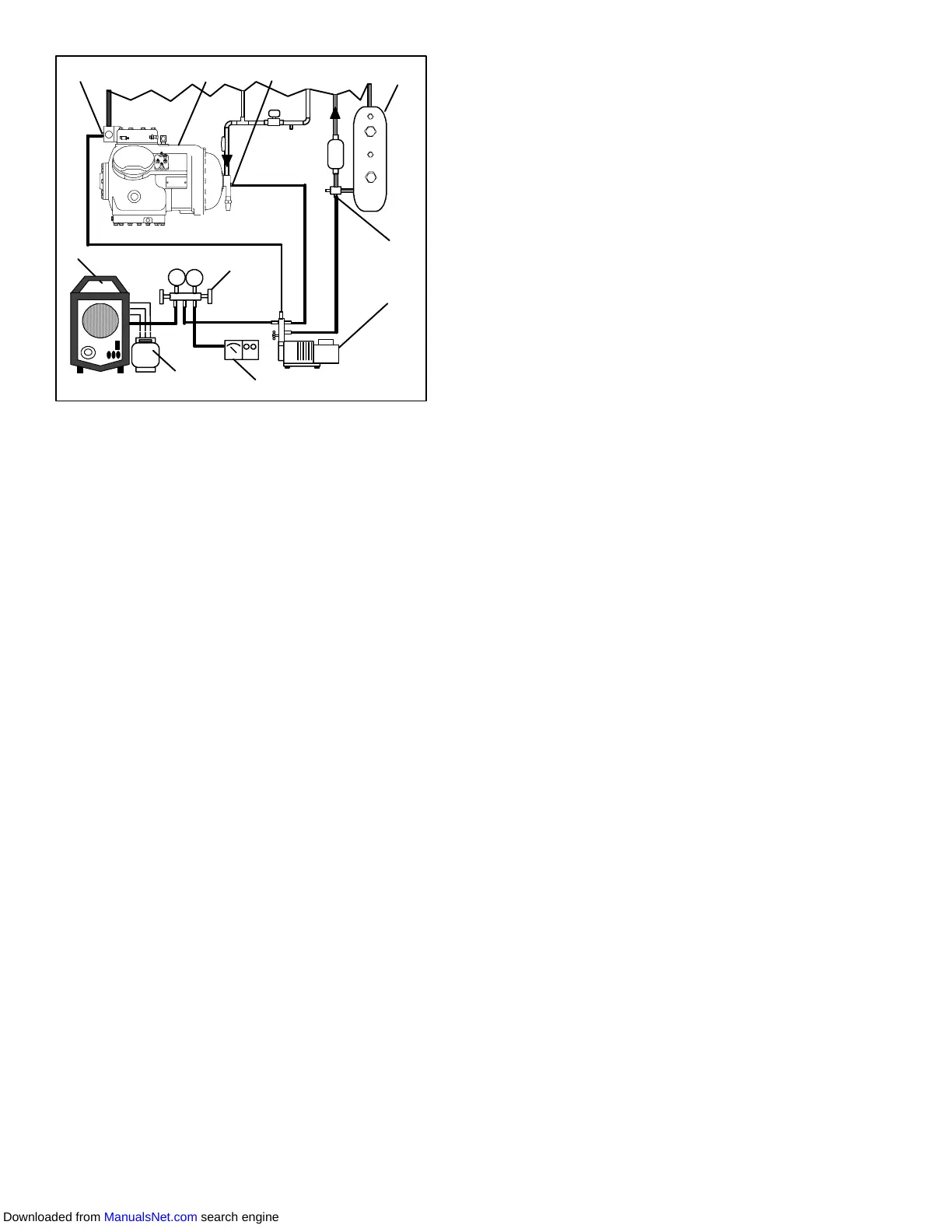

1. Reclaimer

2. Discharge Service

Valve

3. Compressor

4. Suction Service Valve

5. Receiver or Water

Cooled Condenser

6. Liquid Service Valve

7. Vacuum Pump

8. Electronic Vacuum

Gauge

9. Manifold Gauge Set

10. Refrigerant Cylinder

Figure 6-5. Compressor Service Connections

i. Removethe coppertubingandchangethefilter-drier.

Evacuate unit to 500 microns. Close the electronic

vacuumgaugeandvacuumpumpvalves.Shutoffthe

vacuum pump. Wait five minutes to see if vacuum

holds. This procedure checks for residual moisture

and/or leaks.

j. With a vacuum still in the unit, the refrigerant charge

maybe drawn intothe system from arefrigerant con-

tainer on weight scales. Continue to paragraph 6.7

6.6.4 Procedure - Partial System

a. If the refrigerant charge has been removed from the

compressor for service, evacuate only the compres-

sor by connecting the evacuation set--up at the com-

pressor service valves. Follow evacuation proce-

dures of the preceding paragraph except leave

compressor service valves frontseated until evacua-

tion is completed.

b. If refrigerant charge has been removed from the low

side only, evacuate the low side by connecting the

evacuation set--up at the compressor service valves

and liquid service valve except leave the service

valves frontseated until evacuation is completed.

c. Once evacuation has been completed and the pump

hasbeenisolated,fullybackseattheservicevalvesto

isolate the service connections and then continue

with checking and, if required, adding refrigerant in

accordance with normal procedures

6.7 REFRIGERANT CHARGE

6.7.1 Checking the Refrigerant Charge

NOTE

To avoiddamage totheearth’sozonelayer ,use

arefrigerantrecoverysystemwheneverremov-

ing refrigerant. When working with refrigerants

youmustcomplywithalllocalgovernmentenvi-

ronmentallaws. In theU.S.A., refertoEPAsec-

tion 608.

a. Connect the gauge manifold to the compressor dis-

charge and suction service valves. For units operat-

ing on a water cooled condenser, change over to air

cooled operation.

b. Bring the container temperature to approximately

1.7_C(35_F) or --17.8_ C(0_F). Then set thecontrol-

ler set point to --25_C(--13_F) to ensure that the suc-

tion modulation valve is at maximum allowed open

position.

c. Partially block the condenser coil inlet air. Increase

the area blocked until the compressor discharge

pressure is raised to approximately 12 kg/cm@ (175

psig).

d. Onunits equippedwith areceiver,thelevel should be

between the glasses. On units equipped with a water

cooledcondenser,thelevelshould be at the centerof

the glass. If the refrigerant level isnot correct, contin-

uewiththefollowingparagraphsto addor removere-

frigerant as required.

6.7.2 Adding Refrigerant to System (Full Charge)

a. Evacuate unit and leave in deep vacuum. (Refer to

paragraph 6.6.)

b. Placecylinder ofR-134aonscaleandconnectcharg-

ingline fromcylinder toliquid line valve. Purgecharg-

ingline atliquid linevalve andthennoteweight ofcyl-

inder and refrigerant.

c. Open liquid valve on cylinder. Open liquid line valve

half-way and allow the liquid refrigerant to flow into

the unit until the correct weight of refrigerant (refer to

paragraph 2.2) has been added as indicated by

scales.

NOTE

It may be necessary to finish charging unit

through suction service valve in gas form, due

to pressure rise in high side of the system.

(Refer to section paragraph 6.7.3)

d. Backseat manual liquid line valve (to close off gauge

port). Close liquid valve on cylinder.

e. Startunitincoolingmode.Runapproximately10min-

utes and check the refrigerant charge.

6.7.3 Adding Refrigerant to System (Partial

Charge)

a. Examine the unit refrigerant system for any evidence

of leaks. Repair as necessary. (Refer to paragraph

6.5.)

b. Maintain the conditions outlined in paragraph 6.7.1

c. Fully backseat the suction service valve and remove

the service port cap.

d. Connect charging line between suction service valve

portandcylinderof refrigerantR-134a. OpenVAPOR

valve.

Downloaded from ManualsNet.com search engine

Loading...

Loading...