6-7

T -296

2

1

3

4

5

Set screw must be removed.

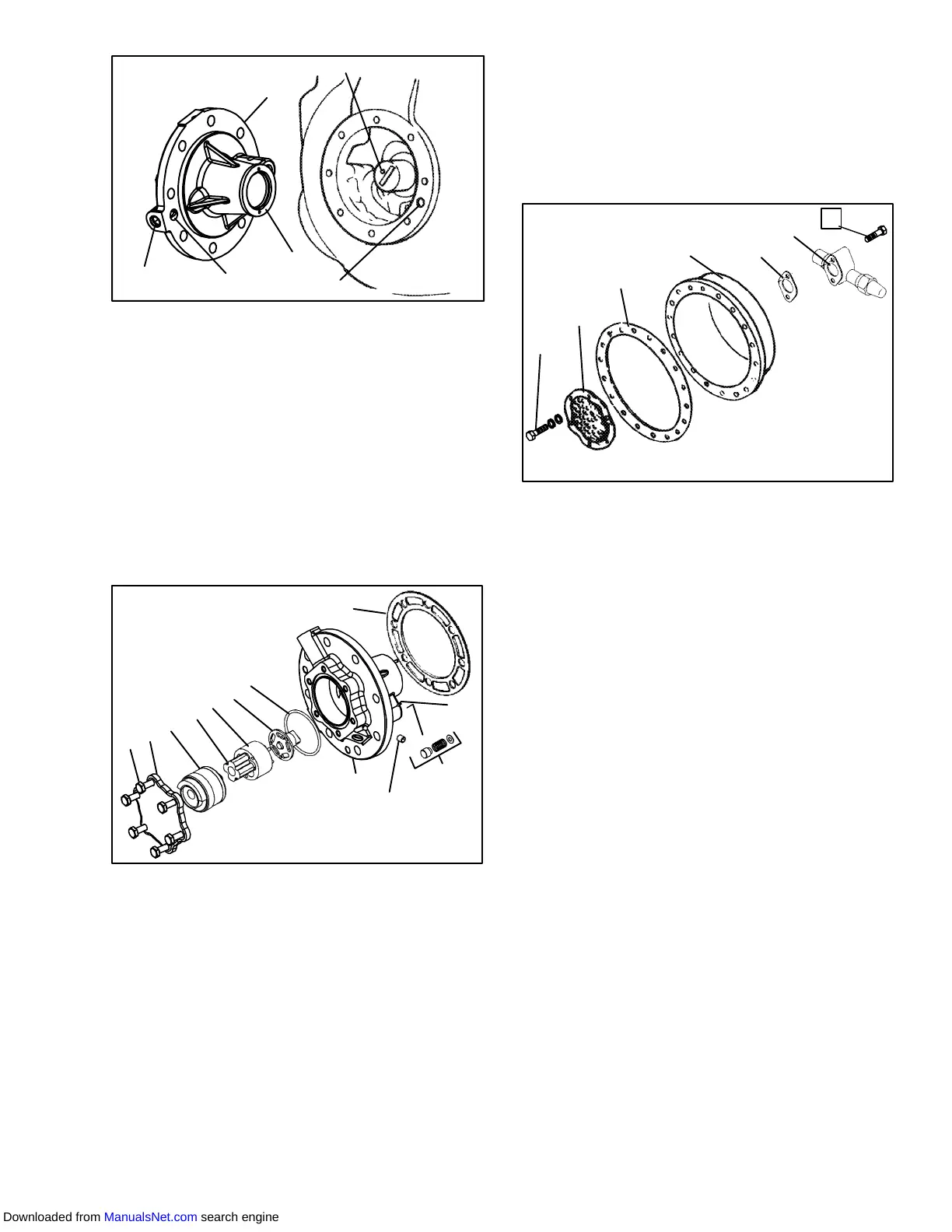

1. Oil Pump & Bearing

Head

2. Thrust Washer

3. Oil Pickup Tube

4. Oil Inlet Port

5. Oil Pump Inlet

Figure 6-9 Oil Pump and Bearing Head

NOTE

If the oil pump was not operating properly, the

entire oil pump & bearing head assembly must

bereplaced.Individualpartsarenotavailable.If

the pump requires inspection or cleaning, dis-

assemble and reassemble by referring to

Figure 6-10.Cleanallparts andcoat allmoving

parts with compressor oil before proceeding

with reassembly.

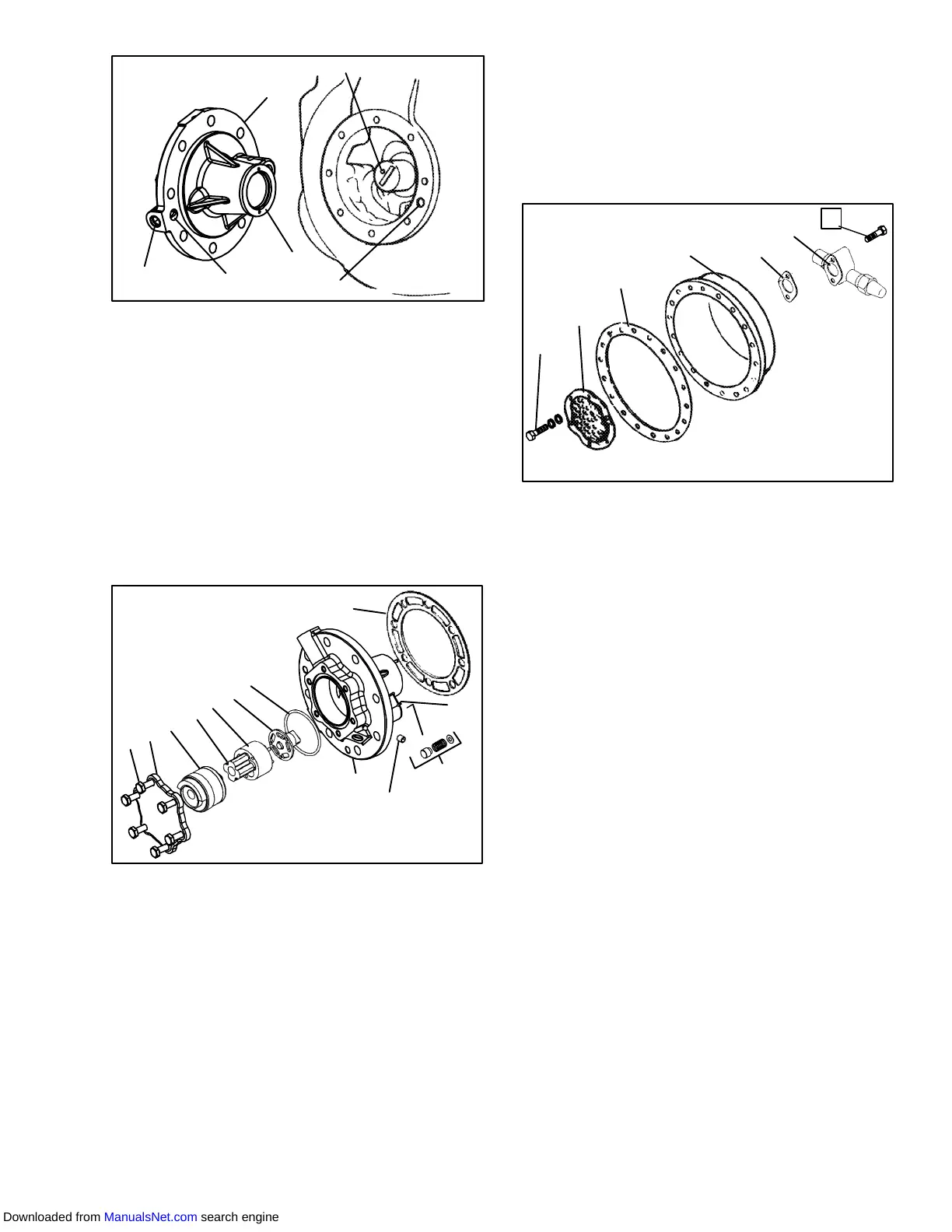

12

1

2

3

4

5

6

7

8

9

10

11

1. Capscrews

2. Cover

3. Reversing Assembly

4. Pinion

5. Gear

6. Drive

7. O-Ring

8. Oil Pump & Bearing

9. Set Screw

10. Relief Valve

11. Pin

12. Gasket

Figure 6-10 Low Profile Oil Pump

h. Be very careful not to damage the motor windings

when removing the motor end cover (see

Figure 6-11), as the cover fits over the winding coils.

Loosen the cap screws, break the seal and then re-

moveallcapscrewsexceptoneinthetopofthecover.

While holding the cover in place, remove the remain-

ing capscrew. Do not allow the cover to drop from its

own weight. To prevent striking the winding, remove

the cover horizontally and in line with the motor axis.

1

2

3

45

6

7

1. Strainer Screws and

Washers

2. Suction Strainer

3. Motor End Cover

Gasket

4. Motor End Cover

5. Valve Gasket

6. Suction Service Valve

7. Valve Capscrew

Figure 6-11 Motor End Cover

i. Remove the refrigerant suction strainer. If it is

removedwitheaseitmaybecleanedwithsolventand

replaced. If the strainer is broken, corroded or

clogged with dirt that is not easily removed, replace

the strainer. Install new gaskets upon reassembly.

j. Block the compressor crankshaft so that it cannot

turn. Use a screwdriver to bend back the tabs on the

lockwasher and remove the equalizer tube and lock

screw assembly. (See Figure 6-12.) The slingers at

the end of the tube draw vapor from the crankcase.

Removetherotorusingajackbolt. Insertabrassplug

intotherotorholetoprevent damage totheendofthe

crankshaft.

k. Ifthepistonringsextendbeyondthecylindertops,the

pistons can be pulled through the bottom plate open-

ing after the piston rings are compressed. A piston

ring compresser will facilitate removal. Each piston

pin is lockedin place bylock ringswhich aresnapped

into grooves in the piston wall. See Figure 6-13

l. Since the stator cannot be replaced in the field, the

terminalplate assemblyneednotbedisturbedunless

a leak exists and the plate assembly needs to be re-

placed. If noterminalplaterepair isrequired,proceed

with reassembly.

Downloaded from ManualsNet.com search engine

Loading...

Loading...