6-6T -296

possible internal pressure by loosening the

bolts and tapping the component with a

soft hammer to break the seal.

CAUTION

Removing the compressor motor press-fit

stator in the field is not recommended. The

rotor and stator are a matched pair and

should not be separated.

When disassembling compressor, matchmark parts so

they may be replaced in their same relative positions.

(See Figure 6-6.) Refer to Table 6-7 and Table 6-8 for

compressor wear limits and bolt torque values.

a. Place the compressor in a position where it will be

convenient to drain the oil. Remove the oil fill plug

(see Figure 6-6) to vent the crankcase. Loosen the

drainpluginbottom plateandallow theoiltodrainout

slowly. Remove the plug slowly to relieve any crank-

case pressure. Some units have a plug in the bottom

center of the crankcase which may be removed for

draining the motor end more quickly.

12 3 4 5 7

6

JACK HERE

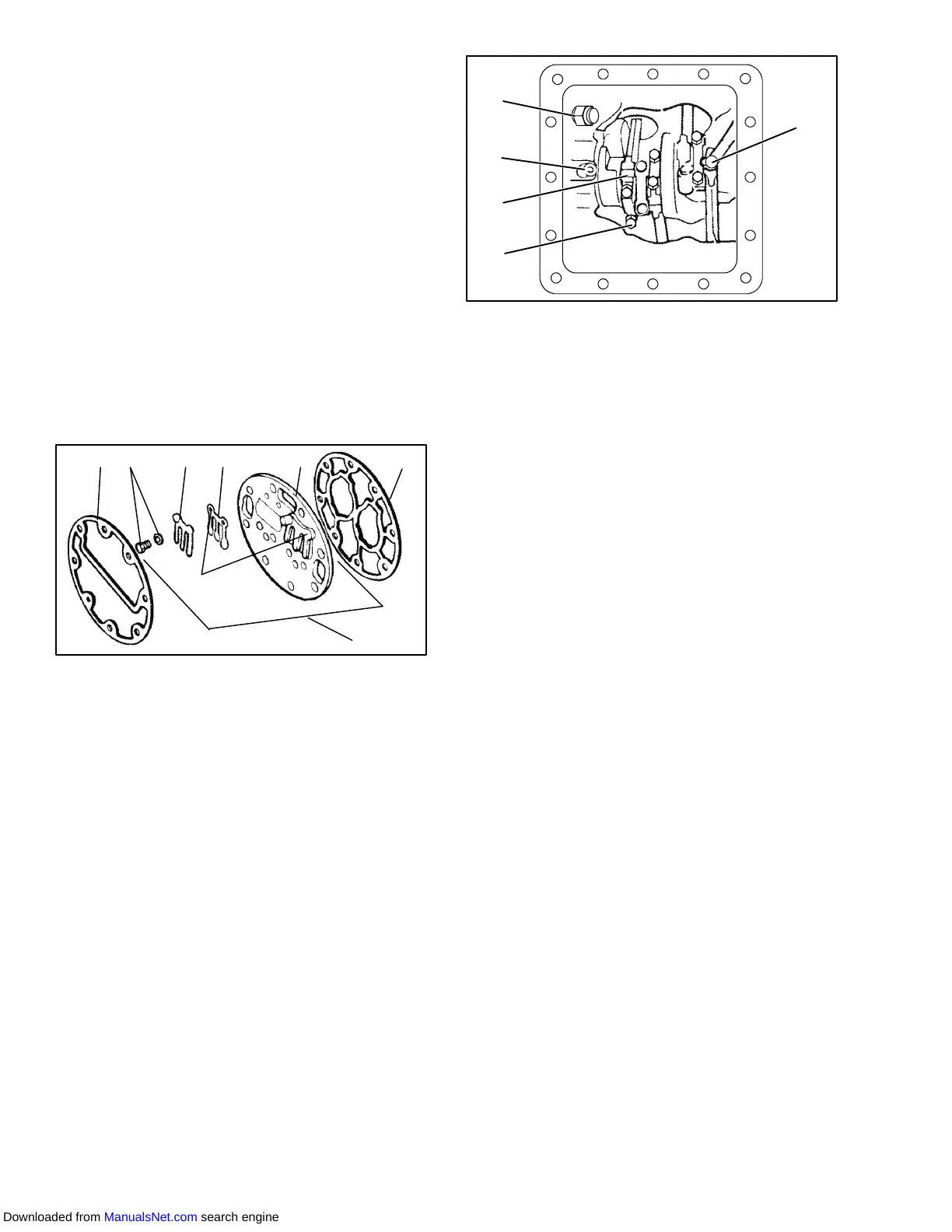

1. Cylinder Head Gasket

2. Discharge Valve

Screw & Lockwasher

3. Discharge Valve Stop

4. Discharge Valve

5. Valve Plate

6. Valve Plate Assembly

7. Valve Plate Gasket

Figure 6-7 Exploded View of Valve Plate

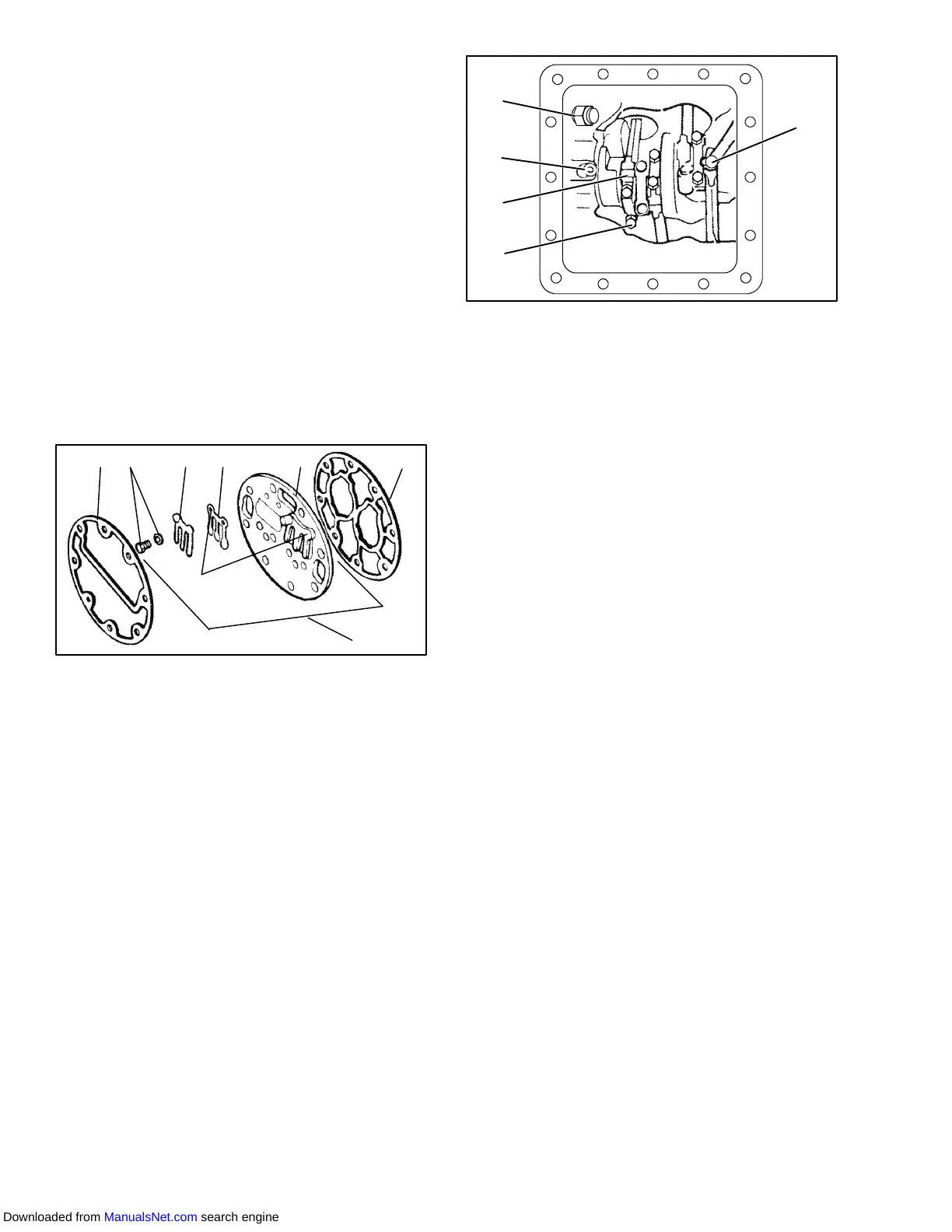

1

2

3

4

5

1. Oil Pressure Relief

Valve

2. Oil Return Check

Valve

3. Oil Suction Tube

4. Capscrew

5. Connecting Rod and

Cap Assembly

Figure 6-8 Bottom Plate Removed

b. Loosencylinderheadcapscrews. If the cylinderhead

is stuck, tap the center of the cylinder head with a

wooden or lead mallet. Do not strike the side of the

cylinderhead.Becarefulnot todroptheheadordam-

age the gasket sealing surface. Remove cylinder

head bolts and gasket (see Figure 6-7).

c. Removevalvestopsandvalves.Aftertheyhavebeen

removed, free the valve plate from the cylinder deck

byusingtheoutsidedischargevalvehold-downcaps-

crew as a jack screw through the tapped hole of the

valve plate. Remove the valve plate gasket.

d. Turn the compressor on its side and remove the bot-

tom plate oil suction screen and screen hold down

plate.Inspectthescreenfor holesor anaccumulation

of dirt. The screen can be cleaned witha suitablesol-

vent.

e.Matchmarkeachconnectingrodcap(seeFigure 6-8)

and connecting rod for correct reassembly. Remove

the bolts and connecting rod caps. Push the piston

rodsupas far astheywillgowithouthavingthepiston

rings extend above the cylinders.

CAUTION

The copper tube which connects to the oil

suction strainer extends out the bottom

with the bottom plate removed. Take pre-

cautions to avoid bending or breaking it

while changing crankcase positions.

f. If necessary, remove the oil return check valve. (See

Figure 6-8.) Inspect it for proper operation (flow in

one directiononly). Replacethe assemblywith anew

unit if check valve operation is impaired.

g. Toremovetheoilpump(seeFigure 6-9)removeeight

capscrews, oil pump bearing head assembly, gasket

and thrust washer.

Downloaded from ManualsNet.com search engine

Loading...

Loading...