148 Chadwick-Helmuth Company, Inc.

Chapter 6 - Maintenance

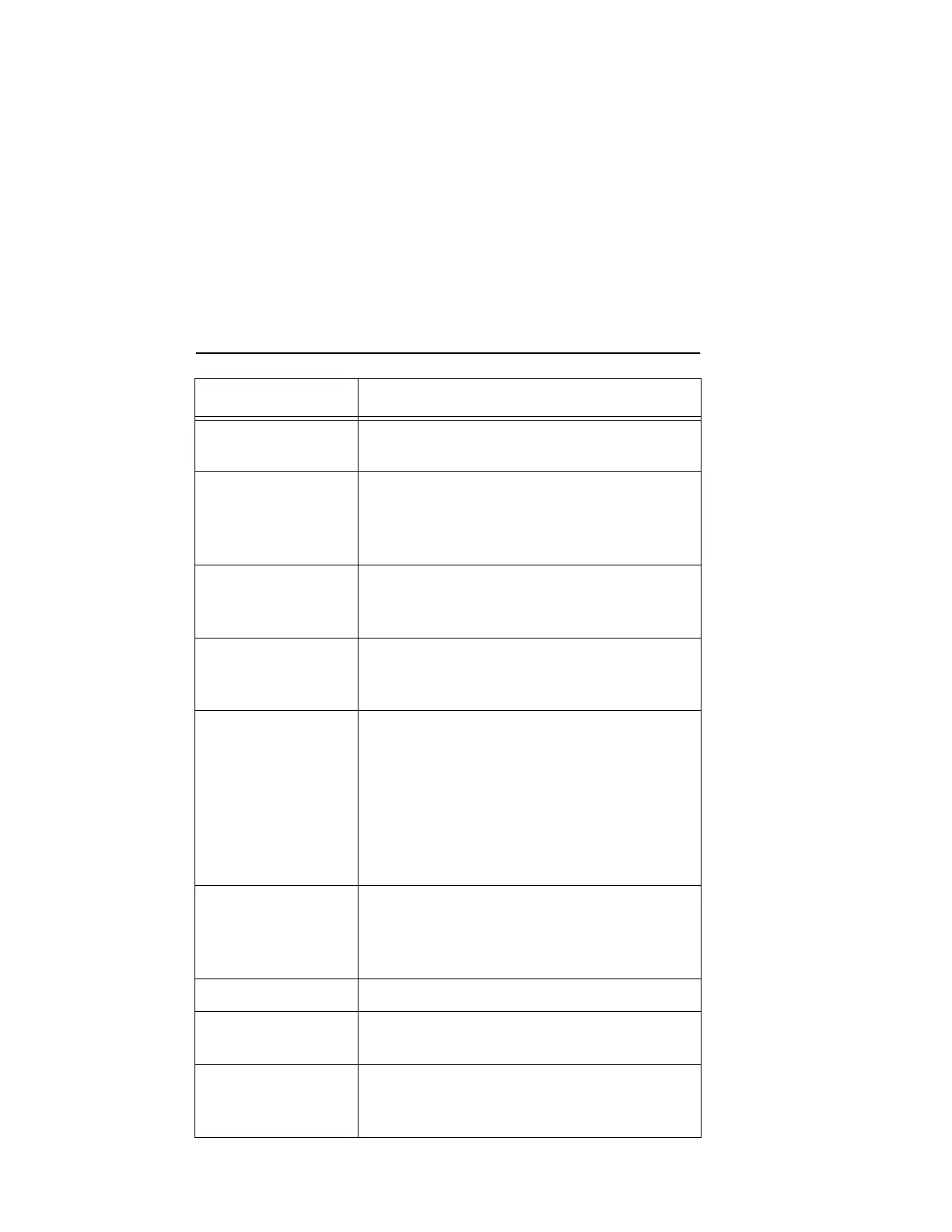

Battery power too

low

Install fresh batteries.

Keyboard ribbon

cable loose or offset

Remove the shield (see Section 6.3.7.2

“Disassembly” on page 143) and check the

ribbon cable for looseness, position, and/or

damage.

Internal short circuit,

battery wire pinched

Remove the connector end plate and carefully

inspect internal wires for damage (see

Section 6.3.7.2 “Disassembly” on page 143).

Internal power

connectors offset or

damaged

Check internal connectors for position,

looseness, and/or damage.

One or both fuses

opened

With an ohmmeter, check the resistance across

each fuse (one each on the two battery contact

PCB assemblies). Resistance must be less than

1Ω. Replace any bad fuse (Ref. No. F1).

Continue to inspect the instrument for the cause

of fuse tripping. This cause could be a pinched

wire, incorrectly installed batteries, conductive

debris, an external cable short, and so on.

Spring is loose and

only making

intermittent contact

Battery contact PCB assembly springs must be

clean and tight. If looseness is a problem, the

eyelet that holds the spring must be re-pressed

or the assembly replaced.

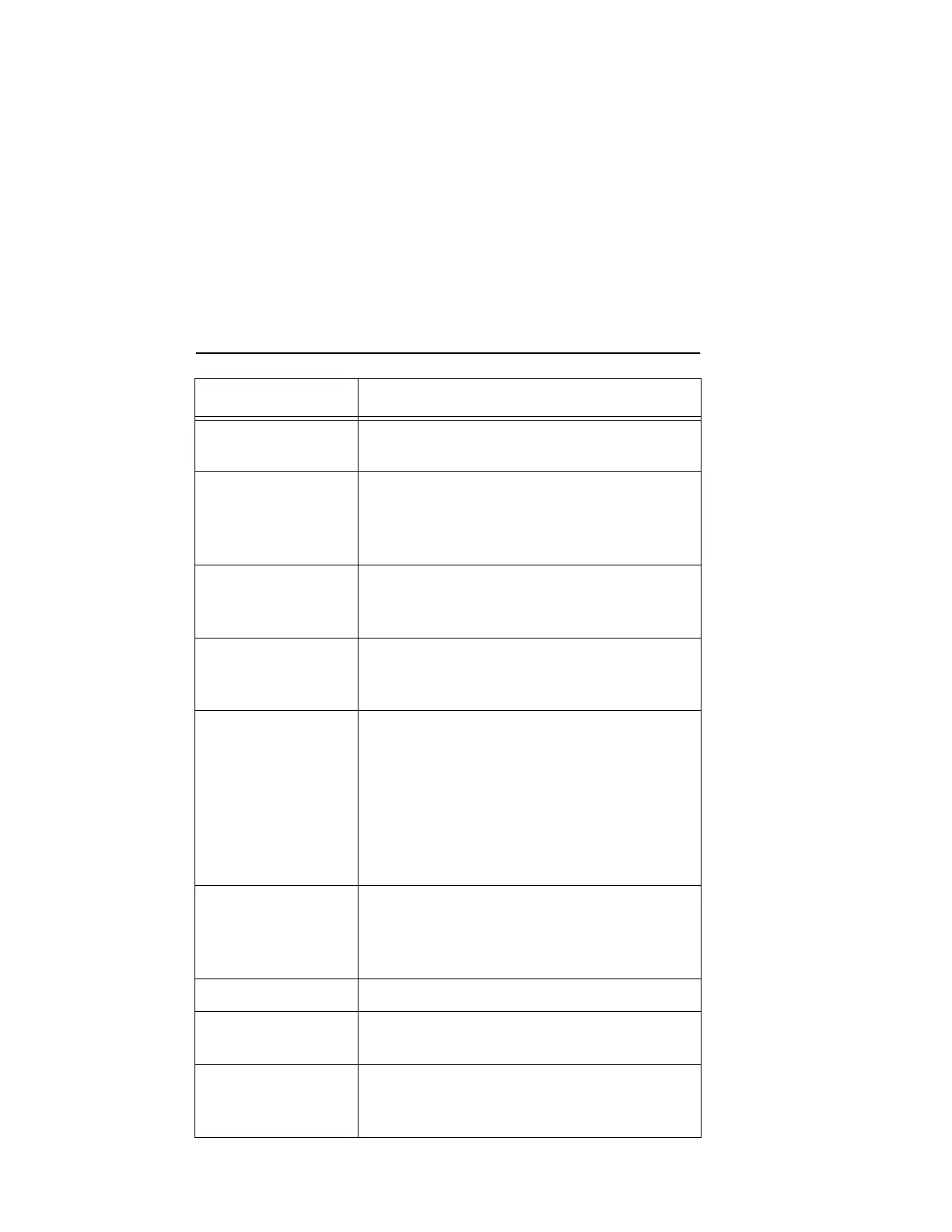

Installation Error Incoming pickup Signal is out of Range.

Ensure target tape “dwell” is long enough for

installation parameters.

If low speed RPM is OK but signal is lost as

speed is increased, make tape wider in beam or

photocell.

Possible Cause Corrective Action (Continued)

Loading...

Loading...