750-265 36

BLOWER MOTOR (J5-6,7)

The blower output will be operated to control a blower motor:

the terminal will be energized at the start of prepurge and

remain on through the end of postpurge, to establish airflow

for those systems that require this function.

EXTERNAL IGNITION TRANSFORMER (J5-4) PILOT VALVE (J5-2) /

MAIN VALVE (J5-3) AND INTERNAL SAFETY RELAY (EXT. IGN/ PV /

MV/ SR)

The burner control turns on the internal safety relay, the load

relays and monitors their feedback to ensure that they are in

the correct state. These relays provide the electrical power to

energize the External Ignition Transformer, Pilot Valve and

Main Valve terminals. If an output is not in its proper state, the

system will respond as defined on initial Setup (typically a

lockout or recycle).

FLAME VOLTAGE (TEST JACKS)

This voltage will represent the flame strength using a 0 to 10V

range, where 0.8 volts indicates the presence of flame.

Burner Control Safety Parameters

(Established by the OEM)

The following parameters may be modified only by using the

process for safety data described in “Commissioning” on

page 16.

The parameters occur here in their order of use in a typical

burner sequence.

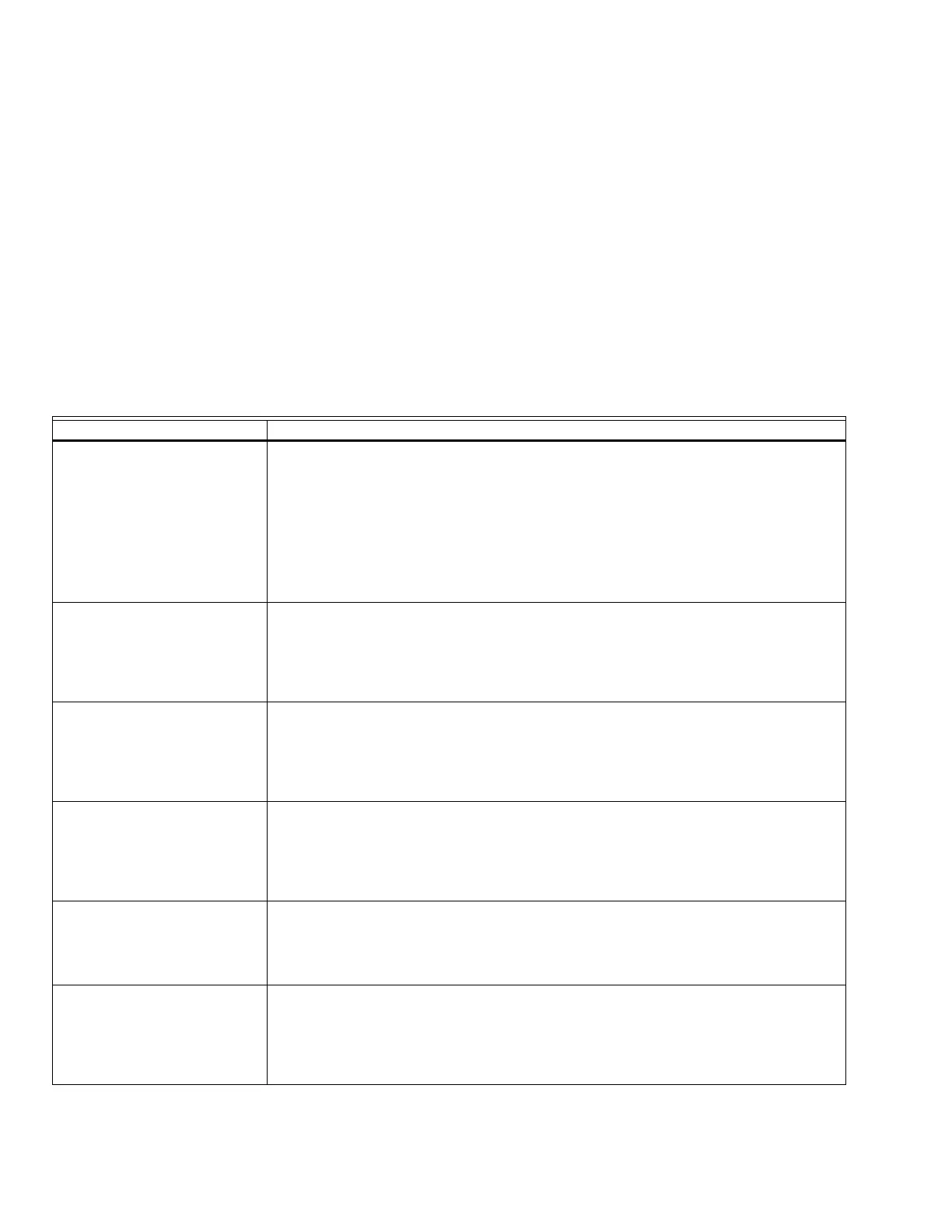

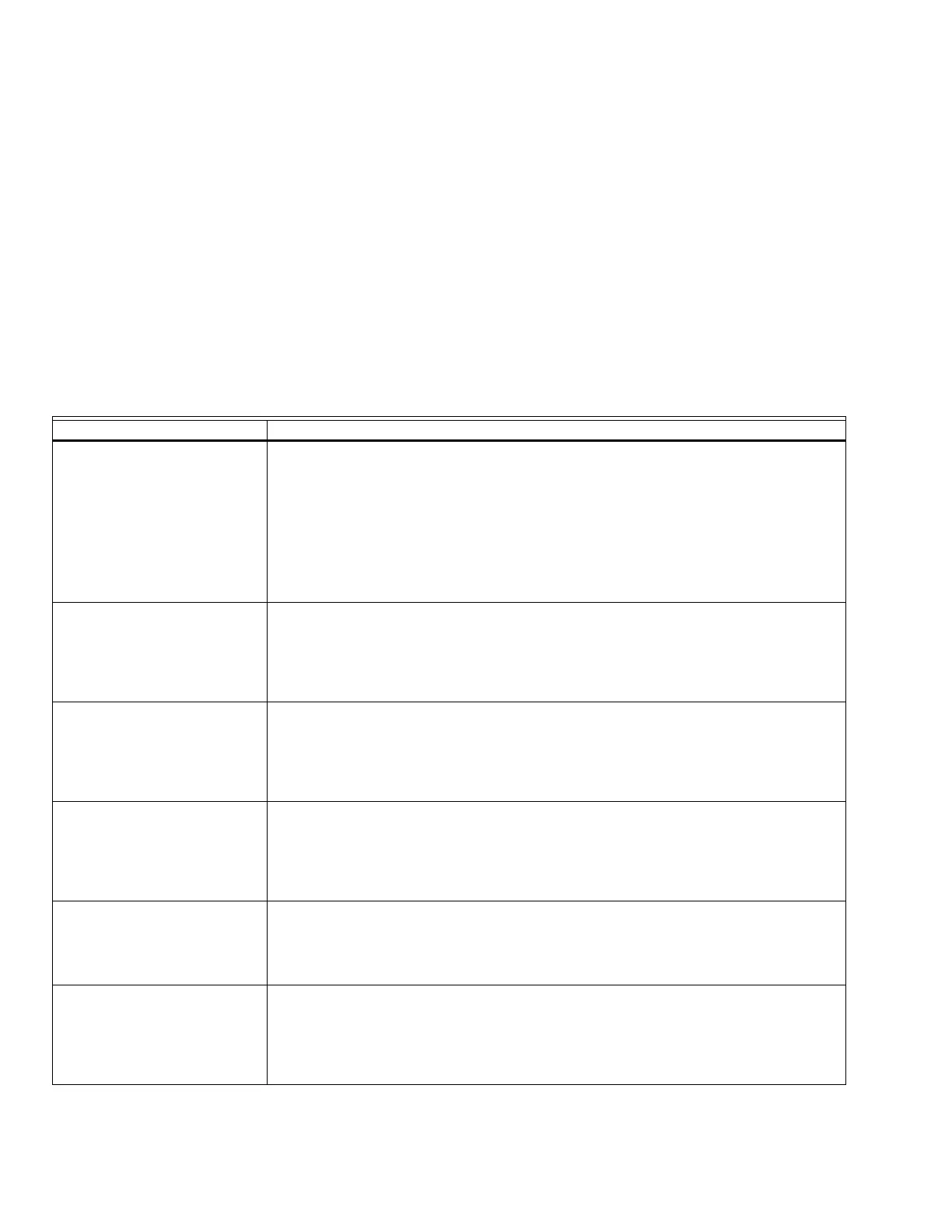

Table 19. Burner Control Safety Parameters.

Parameter Comment

NTC sensor type 10K dual safety, 12K single non-safety

This parameter determines whether 10K or 12K sensors are used for the Inlet, Outlet, Stack,

Header, and Outdoor analog sensor inputs. All sensors must be of the same type: 10K or

12K.

This parameter also determines whether dual sensors are used with a cross-check for the

Outlet, Stack, and DHW sensors. If “10K dual safety” is chosen, these three sensors are each

dual 10K sensors, and if they do not track within 6°F then recycle and hold occurs, until the

sensors are tracking again.

If “12K single non-safety” is chosen, these three sensors are single 12K sensors and the

tracking test is turned off (in this case external safety limits typically are required).

Power up with lockout Enable, Disable

If this parameter is set to disable then a lockout will be cleared by power-cycling the control.

However, if enable is chosen, then clearing a lockout requires either:

• pressing the reset pushbutton, or

• activating the remote reset input, or

• sending a message via Modbus or Enviracom.

LCI enable Enable, Disable

If the LCI input is enabled, then the control will check the LCI as a recycle limit. It must be on

before the burner control will exit the Standby condition and LCI will cause a recycle if it turns

off at other times. If this input is off and demand is present, the burner control will indicate that

it is waiting for LCI so the Annunciator can provide a corresponding value in the Annunciator

Hold parameter, for use by a display.

PII enable Enable, Disable

If the PII input is enabled, then the control will check the PII as a preignition interlock limit. (As

defined by the equipment setup, it typically must be on before the burner control will exit the

Standby condition.) If this input is off and the burner control is in a hold condition waiting for it

to turn on, then the burner control will indicate that it is waiting for PII so that the Annunciator

can provide a corresponding value in the Annunciator Hold parameter, for use by a display.

Interlock start check Enable, Disable

If the Interlock start check is enabled, then the control will check the ILK input as it exits the

Standby condition, in response to demand. If this input is on then the burner control will hold

for 120 seconds waiting for it to turn off. If this hold time expires and the ILK is still on, then a

lockout occurs.

IAS start check enable Enable, Disable

If the Interrupted Air Switch Enable parameter is set to “Disable” then this parameter is

ignored. Otherwise, if the IAS start check is enabled, then the control will check the IAS input

as it exits the Standby condition, in response to demand. If this input is on then the burner

control will hold for 120 seconds waiting for it to turn off. If this hold time expires and the IAS

is still on, then a lockout occurs.

Loading...

Loading...