Section 2 — Installation

Part No. 750-263 2-11

The inlet supply pressure must be as noted in Table A when firing

the boiler at low fire and high fire. Actual gas pressure should be

measured when the burner is firing using a manometer at the

upstream test port connection on the main gas valve. For a multiple

unit installation, gas pressure should be set for a single unit first,

then the remaining units should be staged on to ensure that gas

pressure drop is not more than 1" w.c. and never below the required

pressure. Fluctuating gas pressure readings could be indicative of

a faulty supply regulator or improper gas train size to the boiler.

4. Gas Piping

CFC units are not standardly equipped with an upstream gas

pressure regulator. Therefore, a regulator must be installed at each

CFC unit. Do not use a common regulator to regulate pressure for a

multiple unit installation. Note: Gas connection is at the rear of the

boiler, left hand side as you face the rear of the boiler.

If local code permits, a flexible connection can be used between the

gas line and gas valve. This will enable the burner door to be opened

without disconnecting the gas line.

The regulator for each boiler must be installed with at least 2 feet of

pipe between the regulator and the boiler gas train connection. The

discharge range of the regulator must be able to maintain gas

pressures as noted in Table A.

For buildings or boiler rooms with gas supply pressure exceeding 28"

w.c. a "full lock-up" type regulator is required as well as overpressure

protection (e.g. relief valve).

In addition to the regulator, a plug type or "butterball” type gas

shutoff cock should be installed upstream of the regulator for use as

a service valve. This is also required to provide positive shutoff and

isolate the unit during gas piping tests.

If necessary a strainer should be installed upstream of the regulator

to remove debris from the gas supply.

Drip legs are required on any vertical piping at the gas supply to

each boiler so that any dirt, weld slag, or debris can deposit in the

drip leg rather than into the boiler gas train. The bottom of the drip

leg should removable without disassembling any gas piping. The

connected piping to the boiler should be supported from pipe

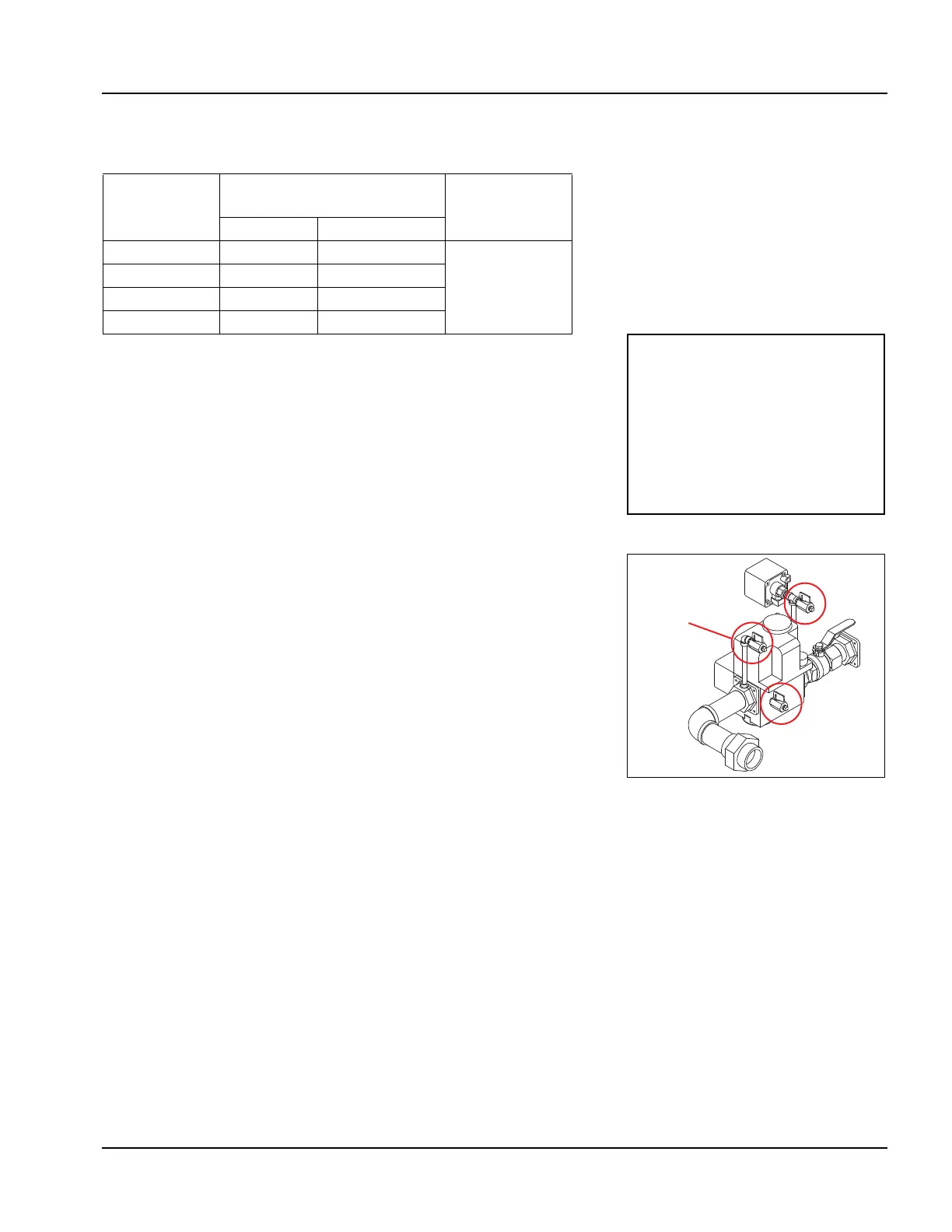

Table 2-1: Gas Pressure

Boiler Input

Pressure Required at gas

train connection

Maximum

allowable

pressure

Low Fire High Fire

500 - 1000 7" w.c. 5" w.c.

14” w.c.

1500 10" w.c. 7" w.c.

1800 7" w.c. 5" w.c.

2500 9.5" w.c. 7" w.c.

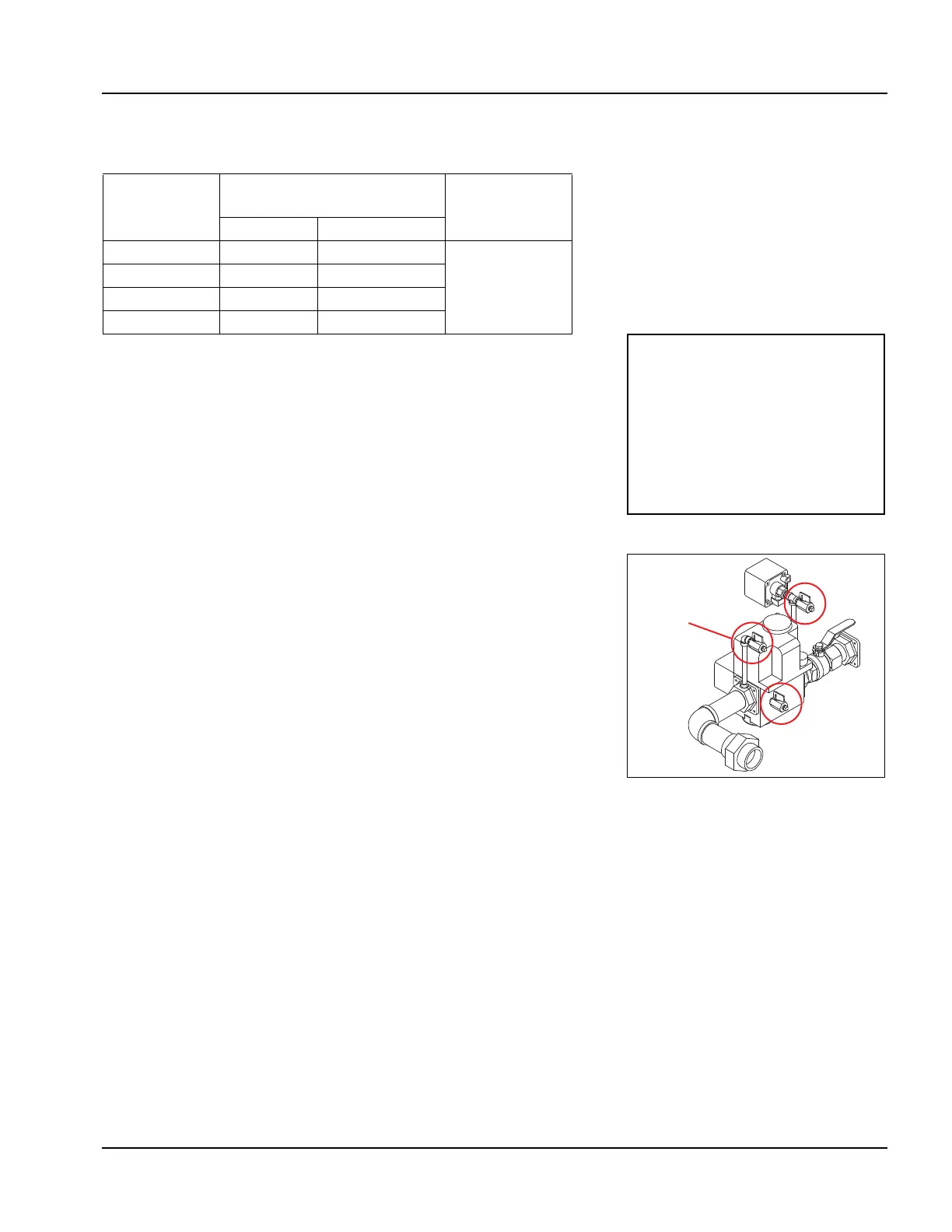

NOTE: The pressure test port is

located at the gas valve inlet

flange (see Figure 2-11). The

remaining try-cocks are for leak

test purposes and should not be

used to measure gas pressure.

Refer to

APPENDIX C - GAS VALVE

INSTALLATION AND MAINTENANCE

for more information.

Figure 2-11 Test cocks - gas

valve

Loading...

Loading...