Section 2 — Installation

Part No. 750-263 2-9

B.FLUE GAS / COMBUSTION AIR CONNECTIONS

The high efficiency of the CFC boiler may cause water vapor to

condense out of the flue gases.

The flue gases from the Model CFC boiler should be removed via a

gas-tight, temperature and corrosion resistant flue gas pipeline.

Only flue gas systems approved and tested by the relevant region or

province are to be connected to the boiler. Refer to flue piping

manufacturer for proper installation and sealing instructions. See

also Chapter 4 of this manual for combustion air and flue gas

venting requirements.

C.WATER TREATMENT

The Model CFC boiler is designed to operate with water chemistry

ranging from a pH value of 8.3 to 9.5 with maximum permissible

oxygen content of 7 ppb. For values outside this range contact your

Cleaver-Brooks representative for assistance.

Corrosion and sludge deposits in old systems must be removed prior

to installation of a new boiler.

Model CFC Water Chemistry

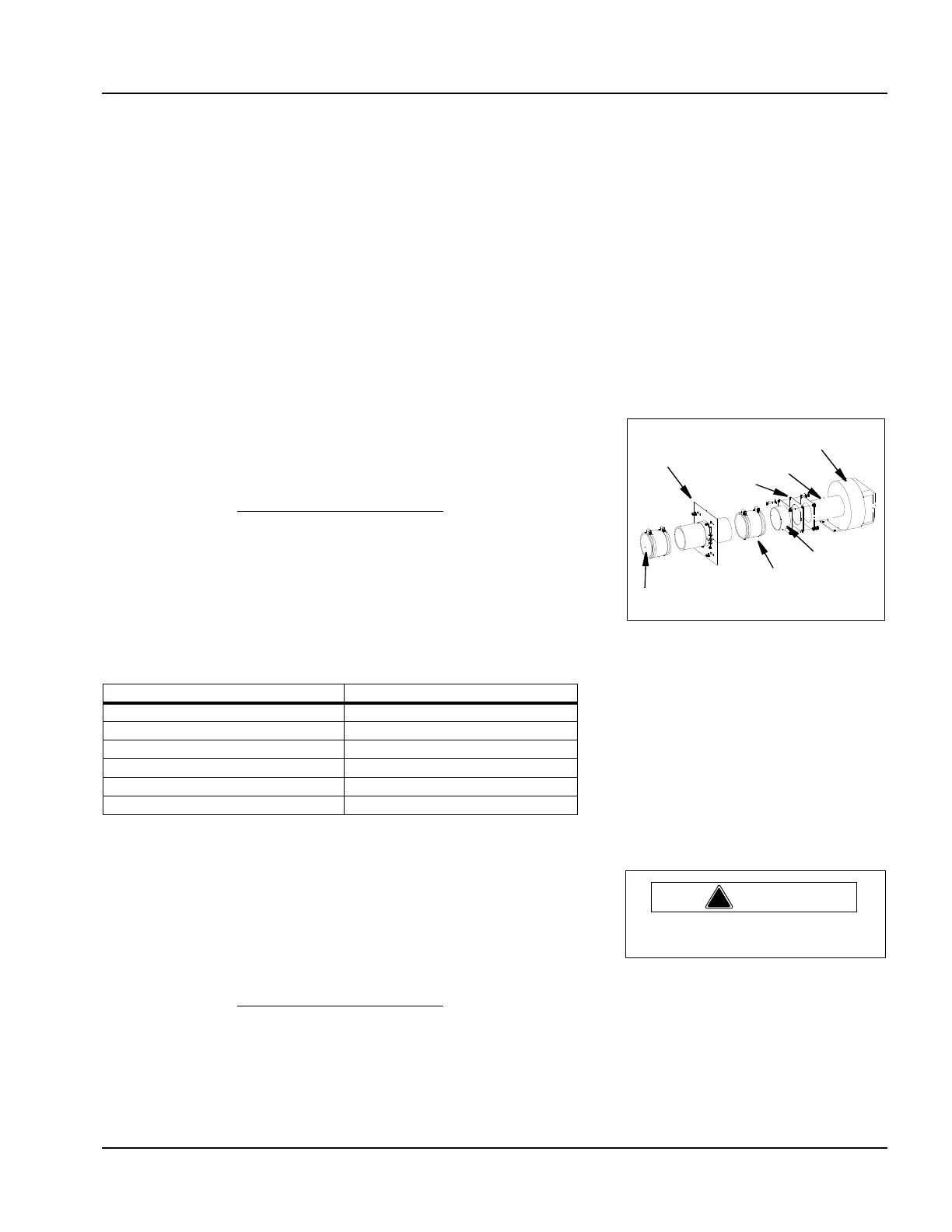

D.BOILER ROOM

The boiler room must comply with all building codes and

regulations. An adequate supply of combustion air is required for

safe operation. If the optional direct vent combustion air kit (Figure

2-8) is not used, ventilation must be provided to meet applicable

regulations for air supply.

See Section 6, Parts, for part numbers for the Direct Vent

Combustion Air kits available.

Figure 2-8 Air Inlet Extension

Fan/Blower

Venturi

Direct Vent Connection

Casing Support

Attachment

Flexible Connection

Adapter Flange

Gasket

Parameter Limit

Glycol 40%

pH 8.3 - 9.5

Chloride 30 mg/liter

Oxygen 0.1 mg/liter

Specific Conductivity 3500 umho/cm

Total Hardness

0 ppm as C

a

CO

3

The boiler must not be installed

on carpeting.

Loading...

Loading...