7 750-265

OVERVIEW

Functions provided by the CB Falcon include automatic boiler

sequencing, flame supervision, system status indication, firing

rate control, load control, CH/DHW control, limit control,

system or self-diagnostics and troubleshooting.

The maximum version of the controller offers:

• NTC-temperature sensor for:

• Outlet Limit And Temperature

• DHW (Domestic Hot Water) Limit and Temperature

• Stack Temperature Limit and Temperature

• Inlet Temperature

• Outdoor Temperature

• Modulating output PWM-driven rotation speed controlled

DC-fan for optimal modulation control.

• Three Pump Outputs with 5 selectable operation modes

• 24Vac or 120Vac (model specific) offer:

• Output control of gas valve (Pilot and Main) and

External Ignition Transformer

• Digital inputs for room limit control, high limit

control, Air pressure switch, Gas pressure switch.

• Optional switches:

• Time of Day switch

• Burner switch

• Easy modification of the parameters on three levels:

• End-user

• Installer / Service engineer

• Manufacturer

• Integrated spark transformer

• Optional external spark transformer

• Optional combined ignition and flame sensing

• Test jacks for flame signal measurement from either a

flame rod or UV flame sensor.

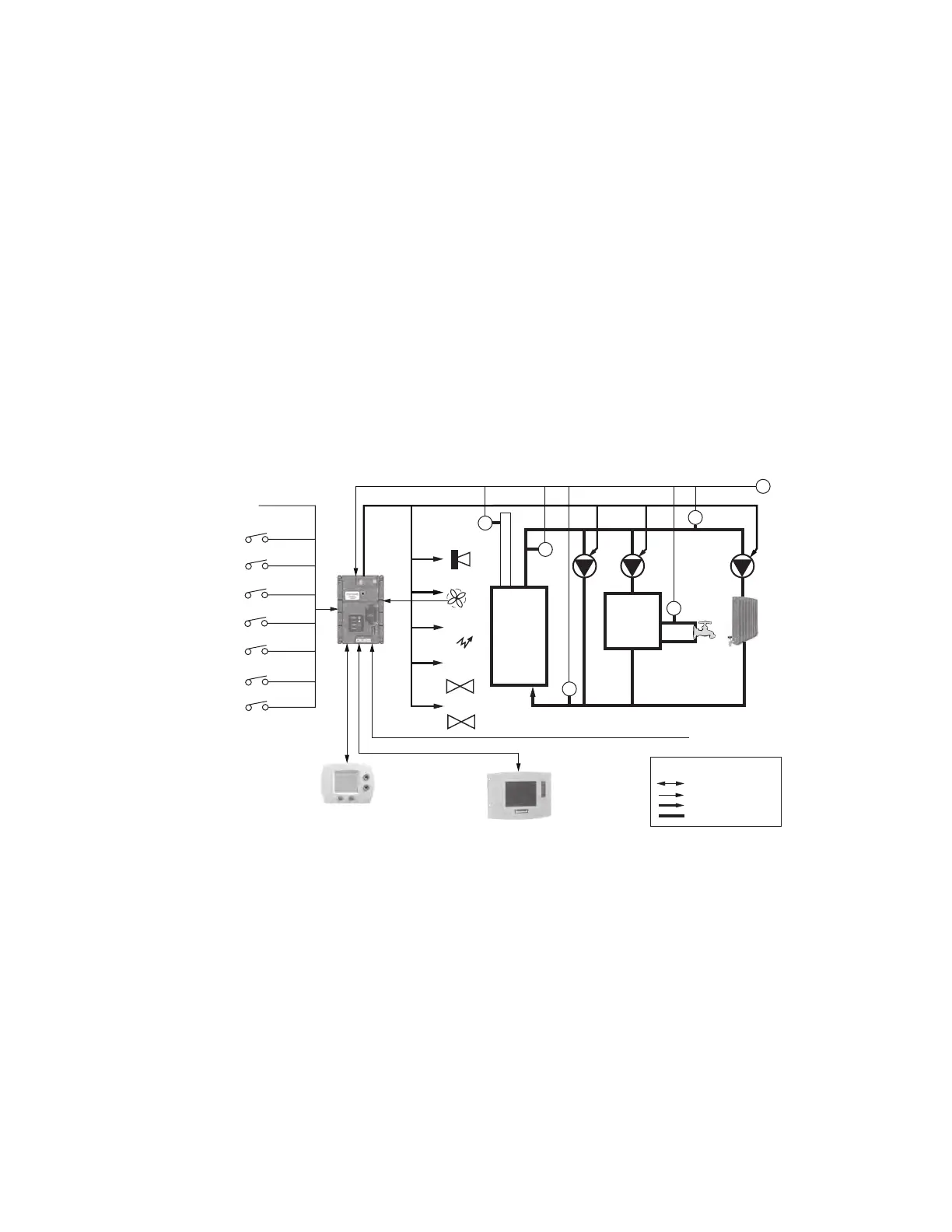

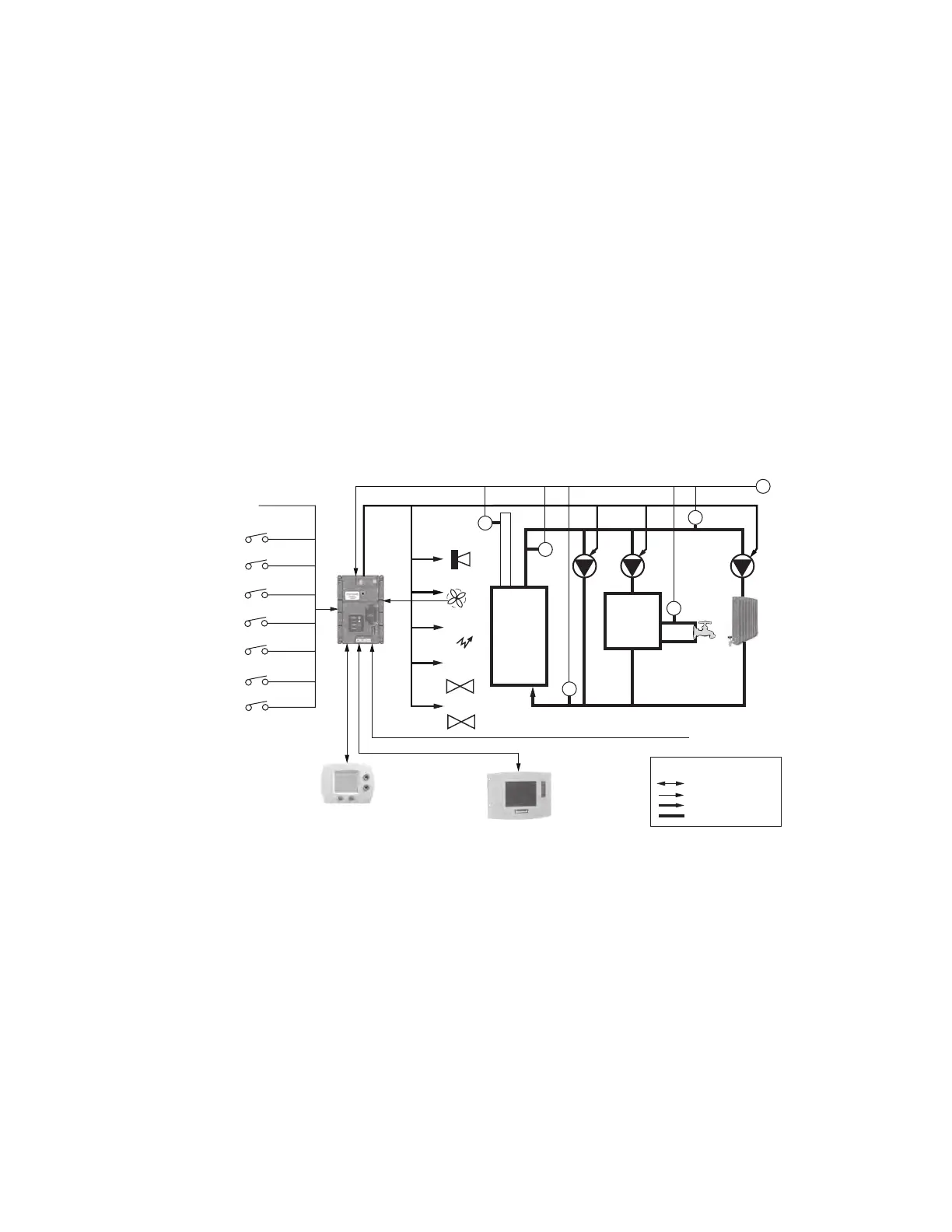

Fig. 1. General hydronic boiler schematic.

Fig. 1 shows two loops of heat control: Central Heating (CH),

and an optional second loop for Domestic Hot Water (DHW)

can be configured on each CB Falcon. The DHW loop transfers

heat from the boiler outlet to hot water appliances in

conjunction with the primary system heat loop. Priority

assignment to each heat loop can be configured to specify

which loop gets serviced first.

COMMUNICATIONS AND DISPLAYS

Three modes of communications are available to the CB Falcon:

• ECOM is used for the S7910 Local Keyboard display for

Falcon monitoring and changing setpoints. Some

equipment setup and checkout is available using the

S7910 along with remote reset of a lockout on the Falcon.

• Local ModBus allows for interfacing to one or all Falcons of

a system and presents them individually to the user. The

833-3577 Operator Interface is a four color touchscreen

display used for configuration and monitoring of the Falcon.

Control Operation and display status in both test

and graphical modes can be shown along with the ability to

setup and displaying trending. The Falcon can also be

remotely reset through the 833-3577 display.

• Global ModBus is a RS485 communications port that

allows configuration and status data to be read and written

to the Falcon. Supports a Master 833-3577 or a Building

Automation master to control the Falcon to respond to a

R7910

HEAT

LOAD

LOCAL

DISPLAY

T

OUTDOOR

TEMP

T

HEADER

TEMP

IGNITOR

FAN

ALARM

STACK

T

T

BOILER

OUTLET

T

T

INLET

FLAME SIGNAL

INTERLOCK(S)

PII

LIMIT(S)

ANNUNCIATION (8)

REMOTE RESET

TOD

STA

T

PILOT

VALVE

MAIN VALVE(S)

DOMESTIC

HOT WATER

TANK

BOILER

MIX

LOOP

DHW

LOOP

M27058

BUILDING

AUTOMATION

SYSTEM

WATER

OUTPUTS

INPUTS

KEY

COMMUNICATION

SYSTEM

DISPLAY

CH

LOOP

Loading...

Loading...