100 Mentor ll User Guide

www.controltechniques.com Issue Number: 12

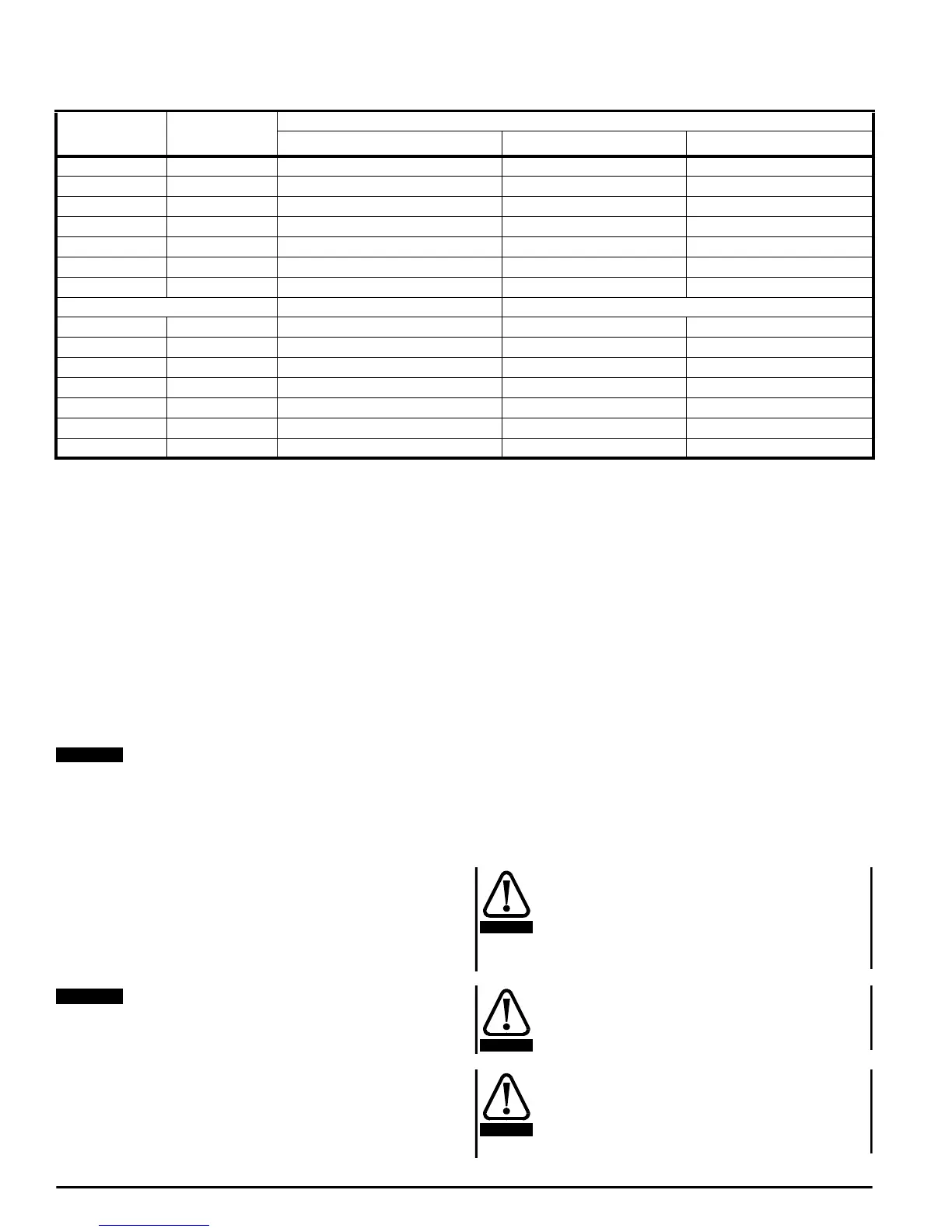

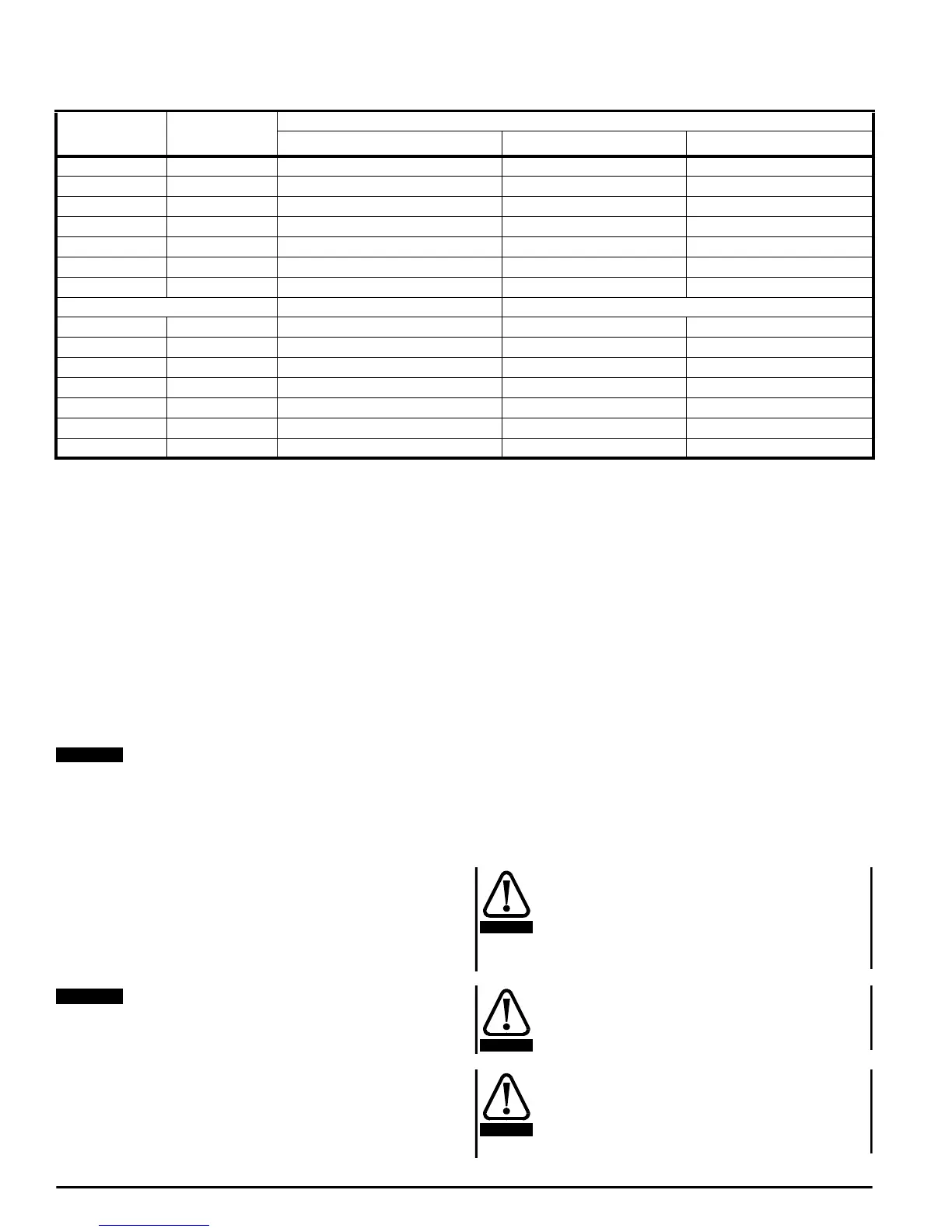

Method 2

RFI filter with low leakage current to earth

Recommended filters are shown in the following table:

• 690V version also available - add the code HV after3359 in the part

number.

Recommended filter for the field regulator

There are several possibilities depending on the main suppression and

how the Drive is connected to the system.

1) Using method 1 for the main circuit, if the capacitor network remains

in circuit at all times when the field regulator is energised, then some low

cost radio frequency chokes (L

F1

and L

F2

) can be used - refer to Figure

12-1

2) Using methods 1 or 2, if the field regulator is operated when the main

suppression is not connected (not illustrated in Figure 12-1), then a

separate RFI filter is required. The filter can be used as an alternative to

RF chokes even if the main filter remains in circuit at all times.

Mentor Drives rated above 210A are normally supplied with a

bridge rectifier to provide a fixed field. The field supply will still

require filtering using either RF chokes or separate filter listed in

the table. The FXM5 external field controller, rated at 20A, may be

filtered in a similar way using the appropriate rated components.

Refer to the Mentor II EMC datasheet.

Radiated emissions

When installed in a standard steel enclosure according to EMC

Installation Guidelines, Figure 12-1the Drive will meet the radiated

emission limits required by the generic industrial emission standard

EN50081-2.

Compliance was achieved in tests using representative enclosures

and following the guidelines given. Every effort was made to

ensure that the arrangements were robust enough to be effective

despite the normal variations which will occur in practical

installations. However no warranty is given that installations built

according to these guidelines will necessarily meet the same

emission limits.

Enclosure construction

For most installations, the Mentor Drive will be mounted in a protective

metal enclosure which may have an internal back-plate for mounting

VSD modules, RFI filters and ancillary equipment. There may be a

requirement to shield the motor cable; if this is the case, electrically bond

the shield to the back plate of the enclosure as shown in Figure 12-1

Alternatively, the shield may be bonded to the enclosure wall at the point

of cable entry using the normal gland fixings.

In some designs the enclosure wall used for cable entry may consist of

separate panels. Bonding the motor cable shield to these surfaces is

acceptable provided they make good electrical contact with the

remaining structure.

Motor cable selection

When testing the Drive module alone, it is necessary to specify the use

of a shielded cable for the motor. This is because the output of the Drive

contains radio frequency energy caused by the switching of the

thyristors. In order to meet the standards specified, if the cable were not

shieldedthenanoutputfilterwouldhavetobeusedinordertoreduce

the radio frequency voltage in the motor circuit to the level required by

the standards. This situation is the same for all DC Drives from all

manufacturers.

It is the responsibility of the owner or user to ensure

that the installation of the Drive and the way it is

operated and maintained complies with the

requirementsoftheHealthandSafetyatWorkActin

the United Kingdom and applicable legislation and

regulations and codes of practice in the UK or

elsewhere.

Safety grounding (earthing) and cabling should

conform to local codes of practice and regulations.

Safety grounding must always take precedence over

the requirements of EMC grounding.

Special consideration is needed It the filter is to be

used in movable equipment where the ground is

connected through a flexible cable and plug/socket.

Additional measures such as a supplementary ground

connection or ground continuity monitoring will be

required.

Drive Line reactors

La, Lb, Lc (µH)

RFI filter for main convertor

Control Techniques part no. 4200 - Voltage rating (V

rms

)50/60Hz

Current rating (A

rms

)at50

o

C

M25, M25R 200 1051 or 6116 440 50

M45, M45R 200 1051 or 6116 440 50

M75, M75R 100 1071 or 6117 440 70 or 63

M105, M105R 100 1111 or 6106 440 110 or 100

M155, M155R 75 1171 or 6107 440 170 or 150

M210, M210R 75 1171 or 6111 440 170 or 180

M350, M350R 35 1301 or 6115 440 300

Schaffner part no.

M420, M420R 27 FN3359-400-99

500* 400

M550, M550R 25

FN3359-600-99 500* 600

M700, M700R 23

FN3359-600-99 500* 600

M825, M825R 19

FN3359-1000-99 500* 1000

M900, M900R 17 FN3359-1000-99

500* 1000

M1200, M1200R 13

FN3359-1000-99 500* 1000

M1850, M1850R 8.6

FN3359-1600-99 500* 1600

NOTE

NOTE

WARNING

WARNING

WARNING

Loading...

Loading...