Mentor ll User Guide 49

Issue Number: 12 www.controltechniques.com

Coiler/uncoiler control mode

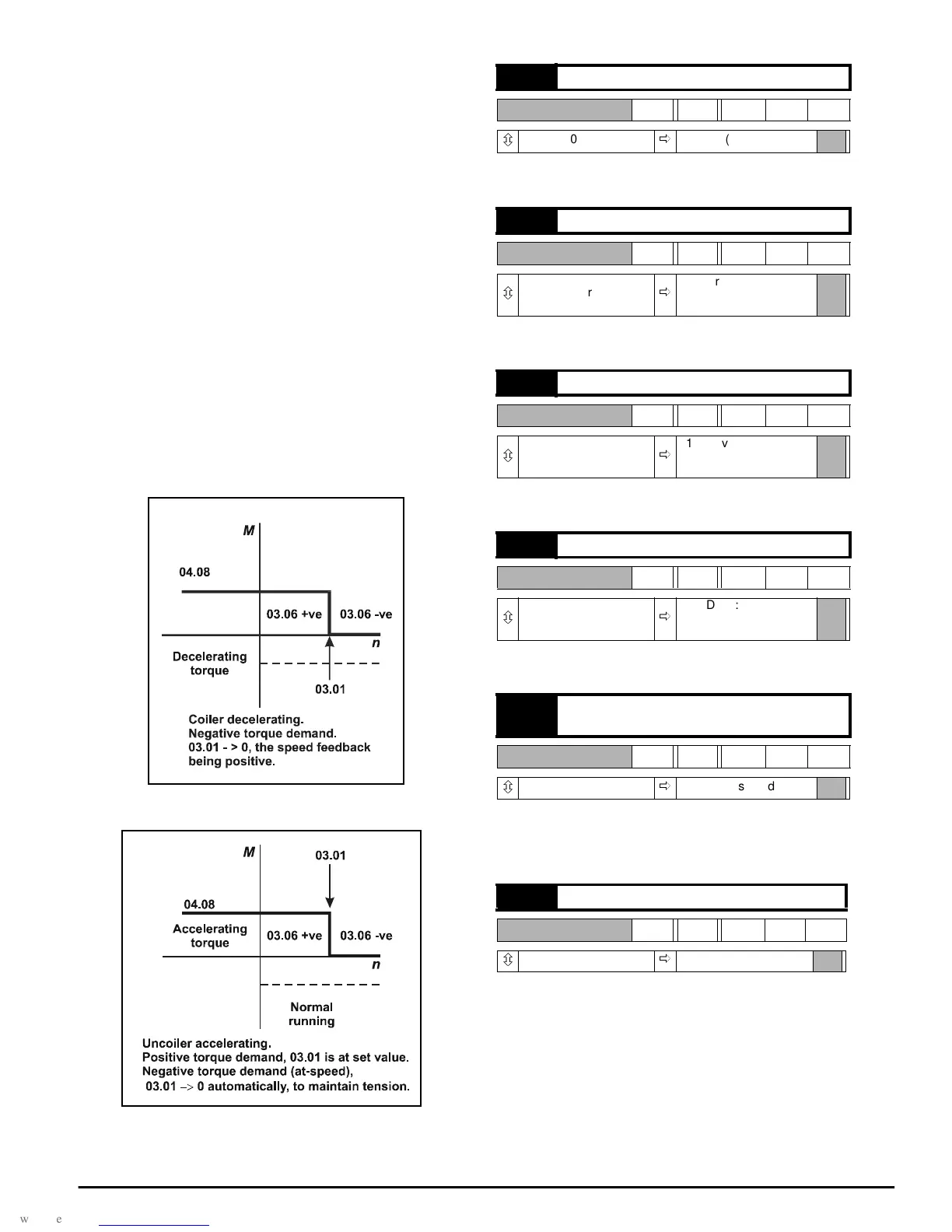

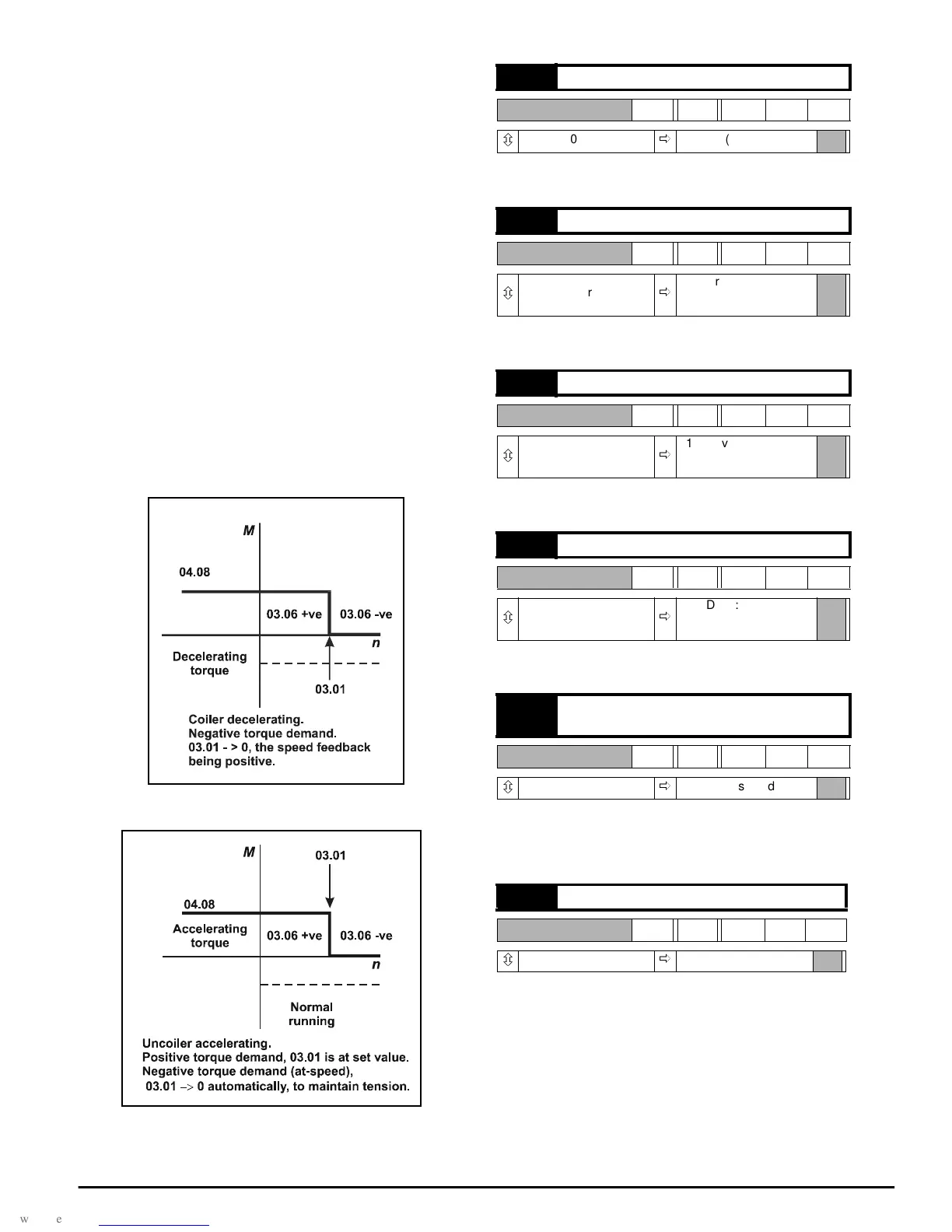

Refer to Figure 8-4 and Figure 8-5.

This mode allows torque to be applied in either sense, for acceleration or

deceleration, while preventing uncontrolled increase in speed or

reversal if the load becomes zero. When the torque demand is in the

sense opposite to that of speed

feedback, this mode automatically selects zero speed reference.

For a coiler, the offset 01.04 should be set just slightly positive so that

03.01 is greater than the line speed reference. When a full reel (of a

coiler) is decelerating, the torque demand may be negative. Since the

speed feedback is positive, the speed reference is automatically made

zero so that the speed errorbecomes negative. Both torque demand and

speed error being negative, decelerating torque is applied.

For an uncoiler, the offset 01.04 should be set just slightly negative so

that there is a negative speed error at zero speed. (Negative speed error

is necessary to produce a negative torque to maintain tension at zero

speed.) As the line speed reference increases, 03.01 becomes positive.

A suitable scaling ofthe input should be applied such that 03.01 is always

greater than the speed feedback, thus maintaining a positive speed error

03.06. Since the speed feedback is positive, zero speed is automatically

selected whenever the torque demand is negative normal operation but

if the torque demand becomes positive then the value of 03.01 becomes

the speed demand, and accelerating torque is allowed, provided that the

reel speed is not greater than 03.01.

For coiler/uncoiler applications, line speed reference corresponds to reel

speed at minimum diameter.

Figure 8-4

Figure 8-5

Quadrant 1 operation is defined as motoring in the forward direction,

speed and torque both having positive values.

Quadrant 2 operation is defined as regenerating in the reverse direction,

speed being negative and torque positive.

Quadrant 3 operation is defined as motoring in the reverse direction,

speed and torque both having negative values.

Quadrant 4 operation is defined as regenerating in the forward direction,

speed being positive and torque negative.

When this bit is enabled, the current limit bridge 2 selector is

automatically changed to 1 after a time interval set by 04.19.TheDrive

can be programmed to select 04.07 automatically at a programmed

time-interval (04.19)afteraRUNsignal.

A time interval up to 255 seconds can be programmed. If 04.18 =1,

current limit bridge 2 is automatically selected when the set time elapses

after a RUN command. This feature is appropriate to applications where

the motor is short-time rated, such as mixing machinery, where the

starting load is high and falls to a lower, constant value only after the

machine has run for some time.

04.14 Quadrant 1 enable

RW Bit

ô

0or1

ð

1 (enabled)

04.15 Quadrant 2 enable

RW Bit

ô

0or1

ð

1Q Drive: 0 (disabled)

4Q Drive: 1 (enabled)

04.16 Quadrant 3 enable

RW Bit

ô

0or1

ð

1Q Drive: 0 (disabled)

4Q Drive: 1 (enabled)

04.17 Quadrant 4 enable

RW Bit

ô

0or1

ð

1Q Drive: 0 (disabled)

4Q Drive: 1 (enabled)

04.18

Enable automatic current limit bridge 2

change

RW Bit

ô

0or1

ð

0 (disabled)

04.19 Current limit timer

RW Uni

ô

0~255

ð

000

Loading...

Loading...