3-8 3-FEATURES

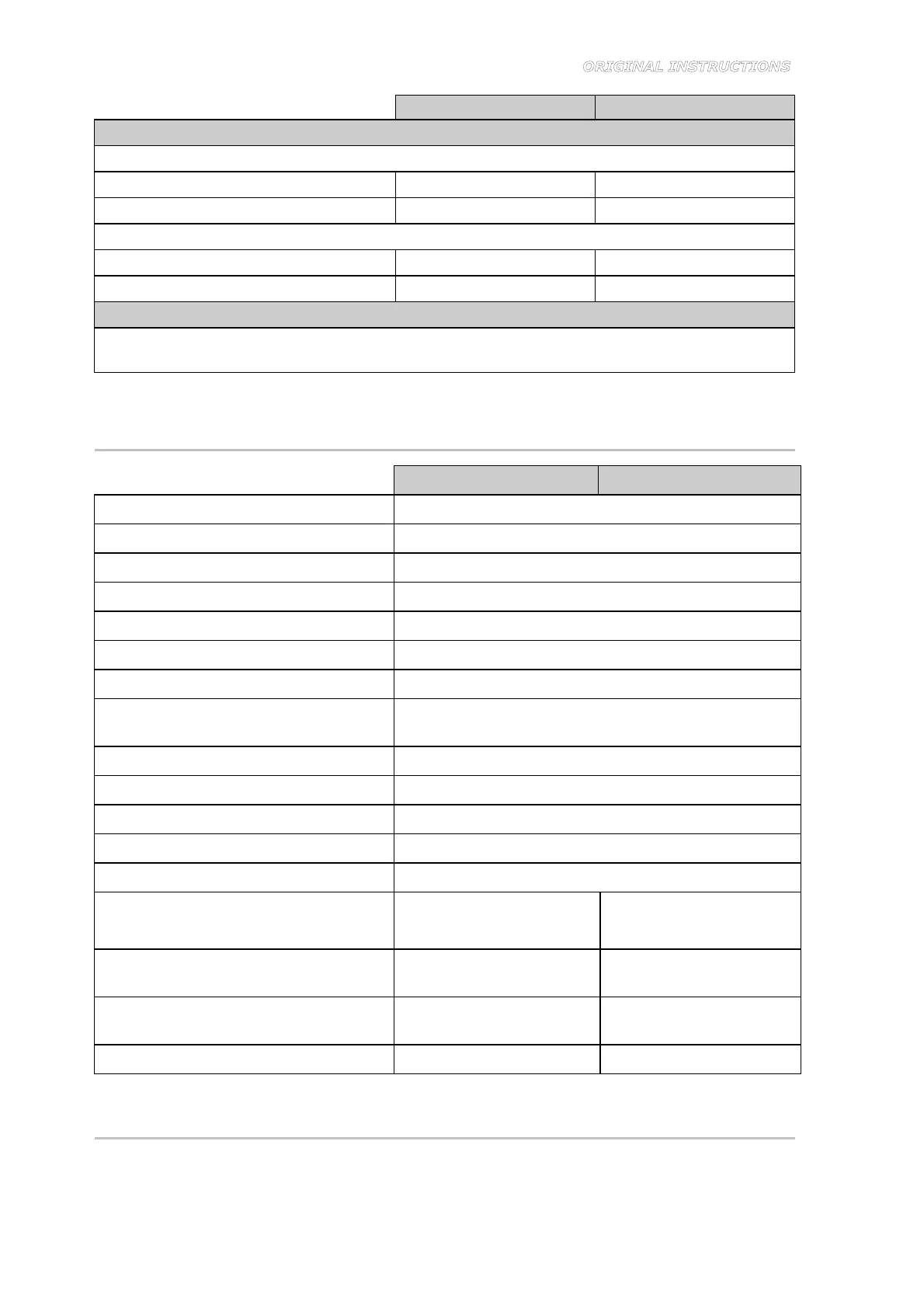

COROB™ TATOCOLOR

COROB™ TATOCOLOR TB COROB™ TATOCOLOR TA

WEIGHT*

COROB™ TATOCOLOR with sheet metal panels

Total machine 208 kg 229 kg

Total packed machine 250 kg 271 kg

COROB™ TATOCOLOR with ABS panels

Total machine 197 kg 211 kg

Total packed machine 239 kg 253 kg

VIBRATIONS

The machine does not transmit vibrations to the floor that may compromise the stability and

precision of any nearby equipment.

* Data are purely indicative, and depend on the exact configuration of the machine and on the number of circuits. The data

refer to the machine with the canisters empty.

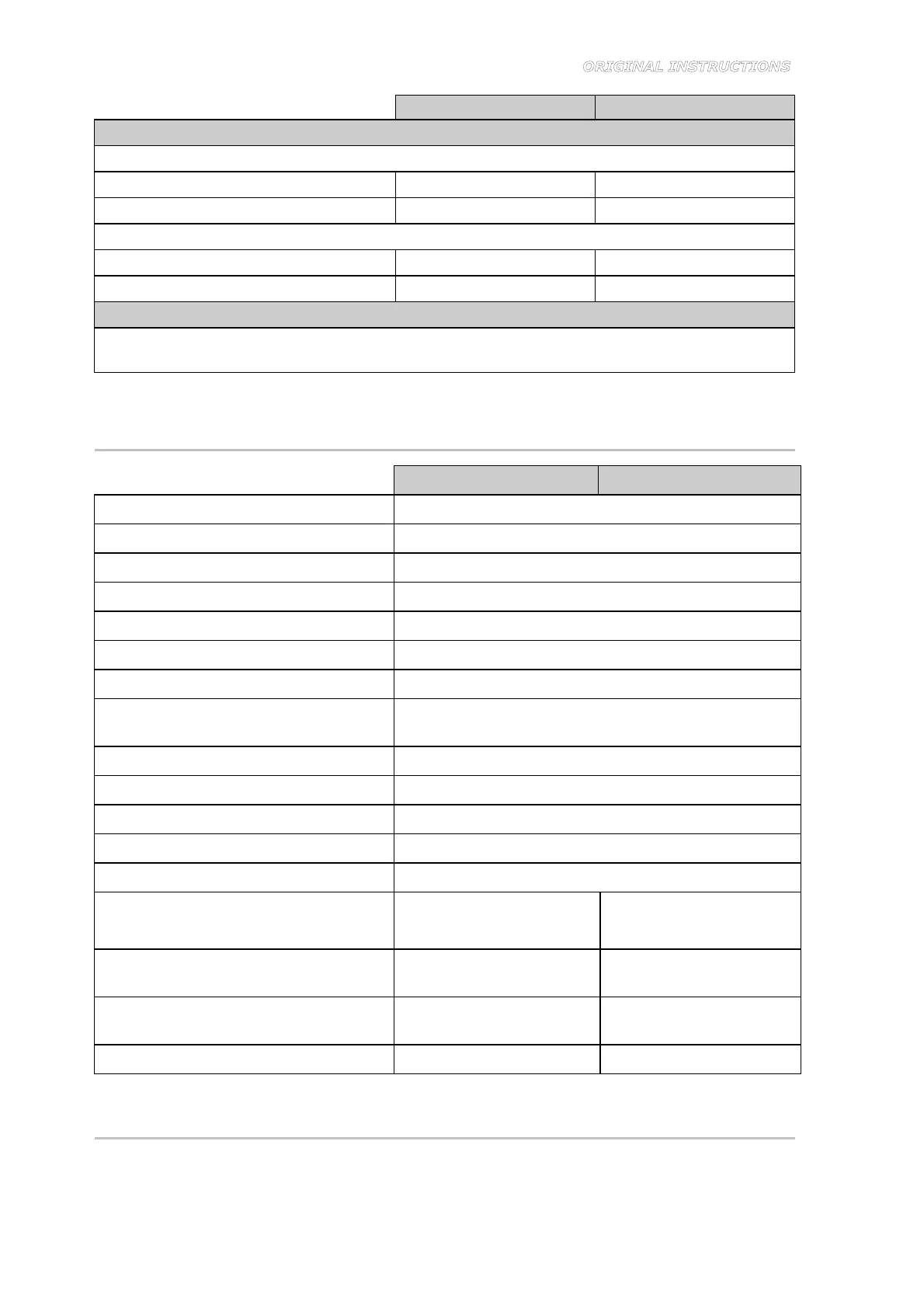

3.4 Performance and characteristics of the machine

COROB™ TATOCOLOR TB COROB™ TATOCOLOR TA

Dispensing system volumetric - simultaneous

Dispensing center internal

Number of circuits up to 16

Canister capacity 3 liters

Type of canisters all-purpose (POM acetalic resin)

Type of electrovalves COROB™ for all-purpose use

Type of pumps with internal gears

Standard circuit flow rate

(theoretical at 100 RPM)

0.5 l/min

Minimum dispensed quantity 1/384 fl oz (0.077 ml)

Standard accuracy

1%

LAB circuit (optional) theoretical flow rate at 100 RPM 0.161 l/min

Nozzle center flow diameter* 31 mm

Shelf manual

Humidifier cap

sliding cap (standard)

sliding autocap (optional)

sliding autocap (standard)

Punch \

manual

(standard)

Plugger \

manual

(optional)

Punch diameter \ 46 mm or 55 mm

* If the cans are pre-punched, the hole diameter must be as follows: flow diameter + 15 mm.

3.5 Cans to be handled

The particular structure and ergonomics of the COROB™ TATOCOLOR automatic dispenser make it

suitable for handling small, medium-sized, and occasionally large cans.

Loading...

Loading...