8-ORDINARY MAINTENANCE 8-5

COROB™ TATOCOLOR

8.5 Checking and replacing the punch tool (model TA)

To work on the punch tool you must remove it; this is possible only by using the special

punch tool screwing/unscrewing device (next chapter).

Every 50 hours (weekly) check the status of the punch tool.

If necessary, clean the internal and external surfaces of the punch tool to remove encrusted

matter, using a cleaning product compatible with the type of bases used in your system.

To prevent base deposits from adhering tightly to the punch tool, we recommend lubricating its

walls with a common, non-contaminant lubricant (we recommend ENOTAP or a similar type).

If the can punching is inadequate because the cutting edge of the punch tool is

excessively worn, replace the worn punch tool.

8.5.1 Using the punch tool screwing/unscrewing device

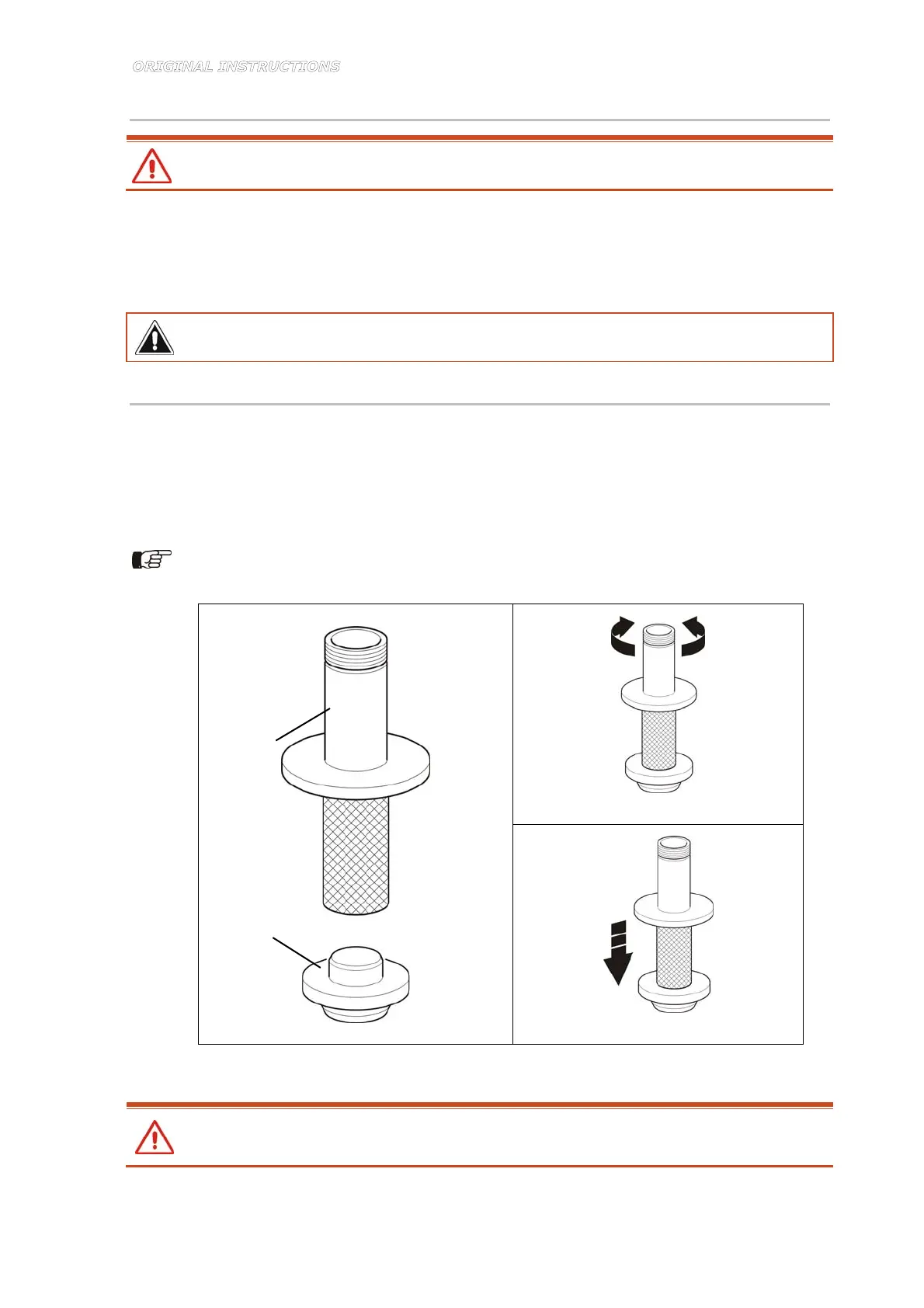

(Figure 8-2)

The punch tool screwing/unscrewing device consists of two parts:

(1) A protected grip with threaded end to remove and reassemble the punch tool.

(2) A manual plugger that can be inserted on the grip to manually apply plastic plugs to

the cans.

The punch is threaded to the left (the reverse of normal screws).

SCREWING/UNSCREWING

PLUGGER

Figure 8-2

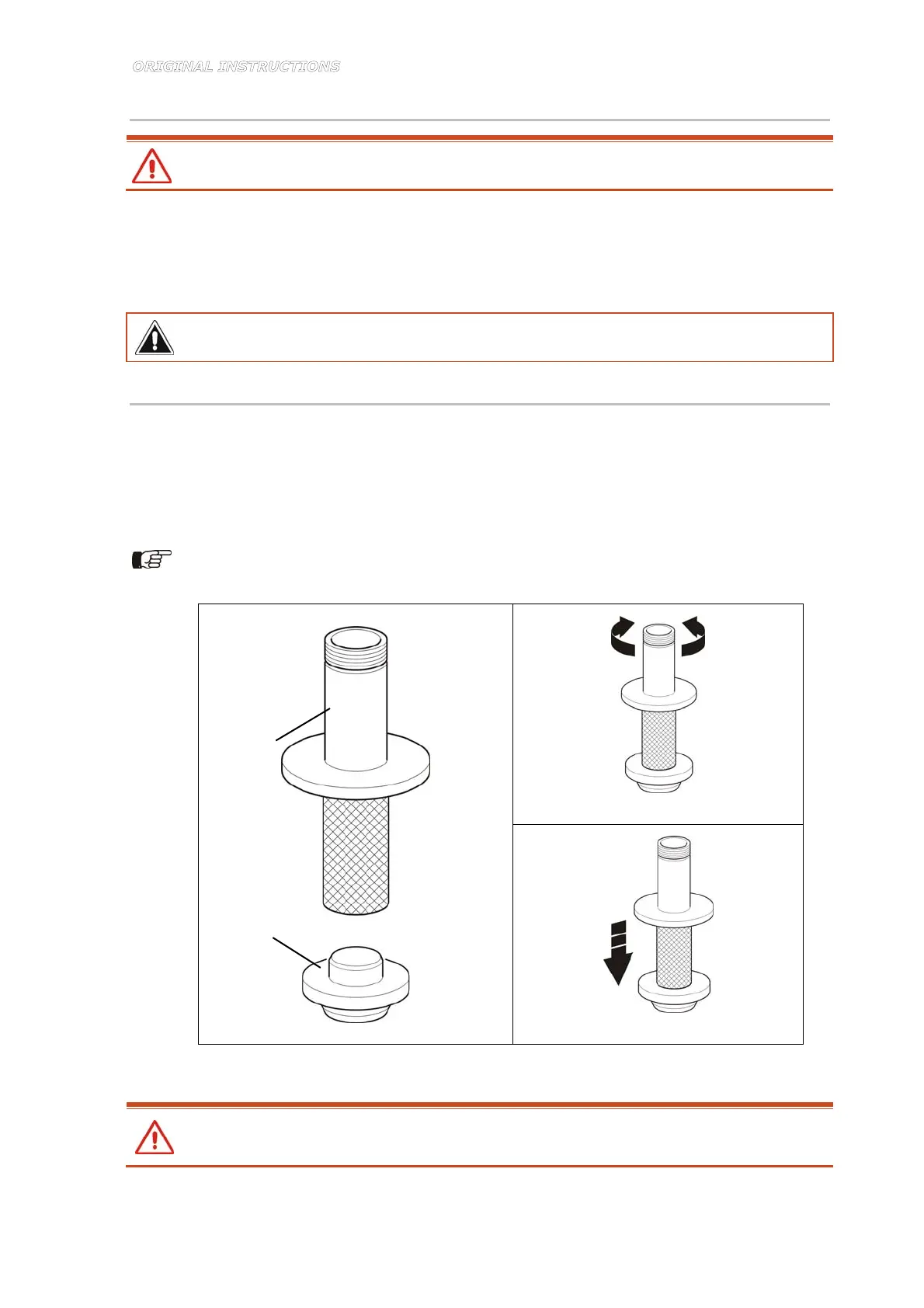

Carefully follow the procedure described below to remove the punch tool:

At least 2 people must work together to remove the punch tool.

RISK OF CUTS.

1

2

Loading...

Loading...