2 — INSTALLATION AND WIRING

Curtis Model 1226 – September 2019

Return to TOC

pg. 4

2 — INSTALLATION AND WIRING

is chapter explains how to mount and wire the controller.

MOUNTING THE CONTROLLER

e 1226 controller can be oriented in any position, but the location should be carefully chosen to

keep the controller clean and dry.

If you cannot nd a clean, dry mounting location you must use a cover to shield the controller from

water and contaminants.

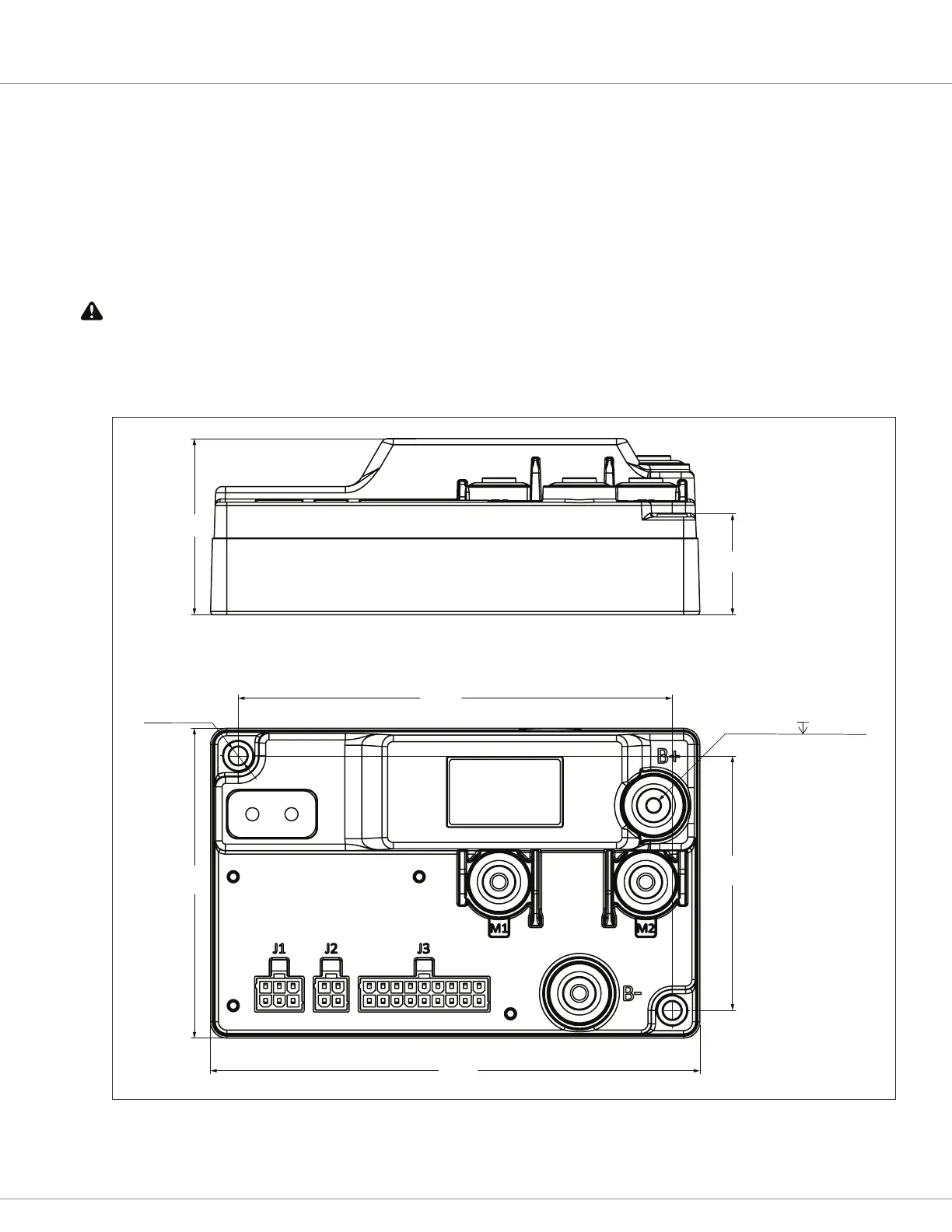

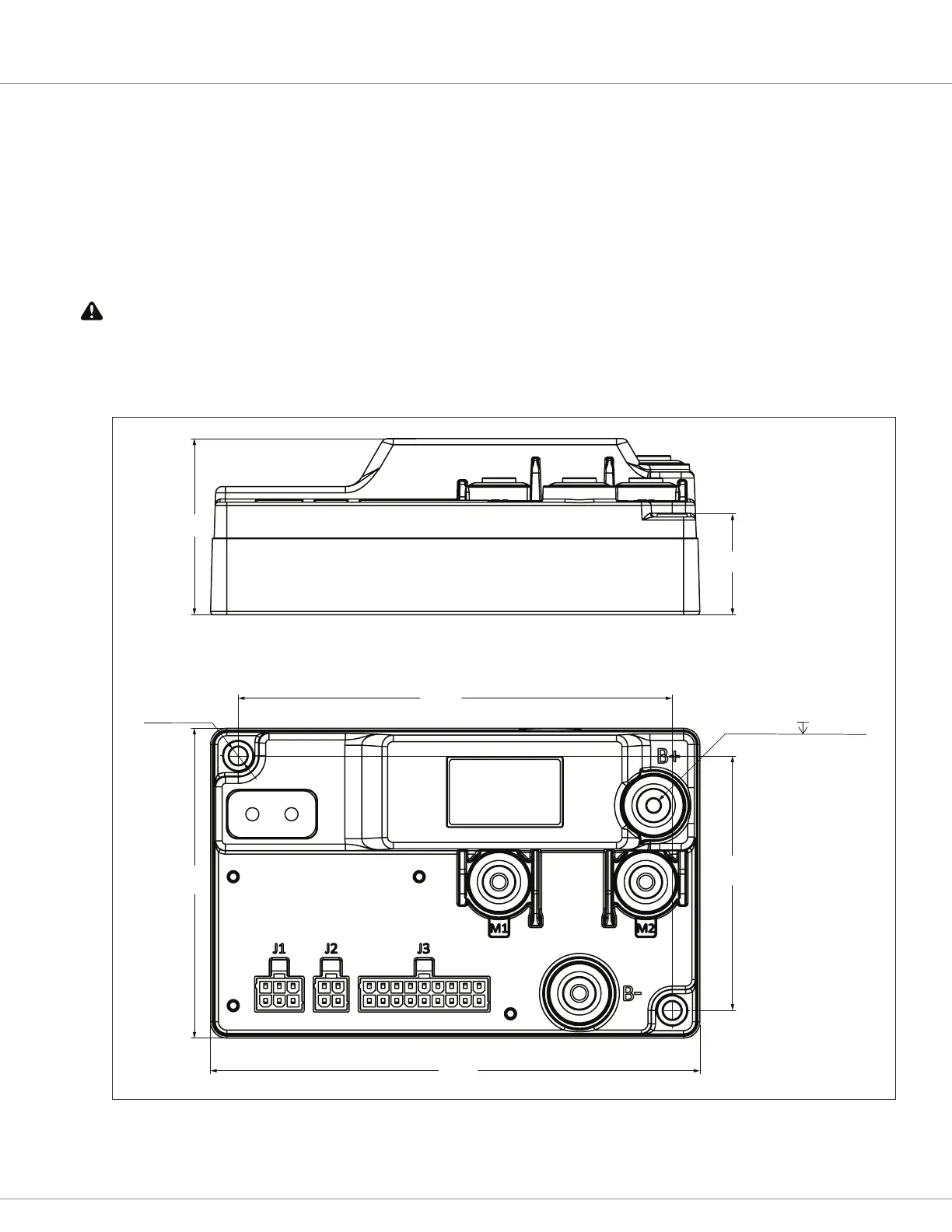

e outline and mounting hole dimensions are shown in Figure 2. e controller should be mounted

by means of the two mounting holes at the opposing corners of the heatsink, using M5 screws.

Figure 2

Mounting Dimensions, Curtis 1226 Controller

150

95

133

78

54

31

1

4

2

3

3 1

46

9

18 10

1

J1 J2 J3

J3-18 Pin

Molex: 39-28-8180

1

KSI

2

Horn Driver

3

Interlock Input/Switch 7

4

EMR NC Input/ Status LED3 Driver/Switch 3/Analog3

5

BDI Output

6

Speed Limit Pot Input/ Switch 2/Analog 2

7

Pot Wiper/ Switch1/Analog1

8

Reverse Input/LED2 Driver/Switch 8

9

Push Input/Switch 9

10

Coil Return

11

Generic Driver 3

12

Generic Driver 2

13

I/O Ground

14

EMR NO Input/Switch 10

15

Charge Inhibit/Switch 11

16

Pot High/Switch 4/Analog 4

17

Forward Input/Switch 12

18

Mode Input/LED1 Driver/Switch 13

Mating connector:Molex 39-01-2180 with appropriate 45750-series crimp terminals.

J2-4 Pin

Molex:39-28-8040

1

Serial RX/CAN L

2

I/O Ground

3

Serial Tx/CAN H

4

EXT_+14V

Mating connector:Molex 39-01-2040 with appropriate 45750-series crimp terminals.

J1-6 Pin

Molex :39-28-8060

1

EXT_+5V

2

Speed Sensor Input/ Switch6/Analog6

3

Generic Driver 1

4

Brake+

5

I/O Ground

6

Motor Temp Sensor Input/Switch5/Analog5

Mating connector:Molex 39-01-2060 with appropriate 45750-series crimp terminals.

8 36742

LABEL^WARRANTY (FINISHED GOODS)

1

7

17751301-02

COVER^FOR 1226

1

PLASTIC

6 17751300

BASE PLATE FOR 1226BL

1

ALUMINUM ALLOY

5 17751303

BUSBAR^UVW FOR 1226BL

3

ALUMINUM ALLOY

4 17751305

SEAL PLUG FOR BUSBAR

4

RUBBER

3 17751304

BUSBAR B+ FOR 1226BL

1

ALUMINUM ALLOY

2

18201014-408

POD LABEL

1

4X M5X 0.8 10 MIN

2X Ø 5.50

Loading...

Loading...