22

MAGFLO

â

3. Product selection guidelines

Product selection

guidelines

The Danfoss cleaning unit can be used with MAG 5000 or 6000 in rack mount versions.

The cleaning unit can be used in applications where the liner material and subsequently the

electrodes may be coated with deposits. If the coating is electrically insulating, the electrode signal

will be reduced. If the coating is electrically conductive, the electrode signal will be partly short-

circuited. In both cases the accuracy of the meter will decrease (dependent on the type and thickness

of the coating).

Note

The cleaning unit cannot be used for flammable or explosive media!

Empty pipe detection and cleaning facility cannot be used at the same time.

The cleaning unit cleans the electrodes electro-chemically by applying a voltage to the electrodes

for approx. 60 sec. While cleaning, the signal converter stores and holds the latest measured flow

reading on the display and also the signal outputs. After an additional pausing period of 60 sec. the

flowmeter resumes normal measurement and the cleaning is now completed.

The relay in the signal converter activates the cleaning cycle. In the relay output menu (under

cleaning) the cleaning interval can be set between 1 hour and 24 hours.

Cleaning should only take place with liquid in the pipe. This can be achieved via the empty pipe

detection. It is therefore recommended to select “empty pipe detection” ON when using the cleaning

unit.

The cleaning sequence can also be controlled manually through the electrical input of the signal

converter. Before this is done, ensure that the measuring pipe is full.

Theory of operation

3.4

Cleaning unit

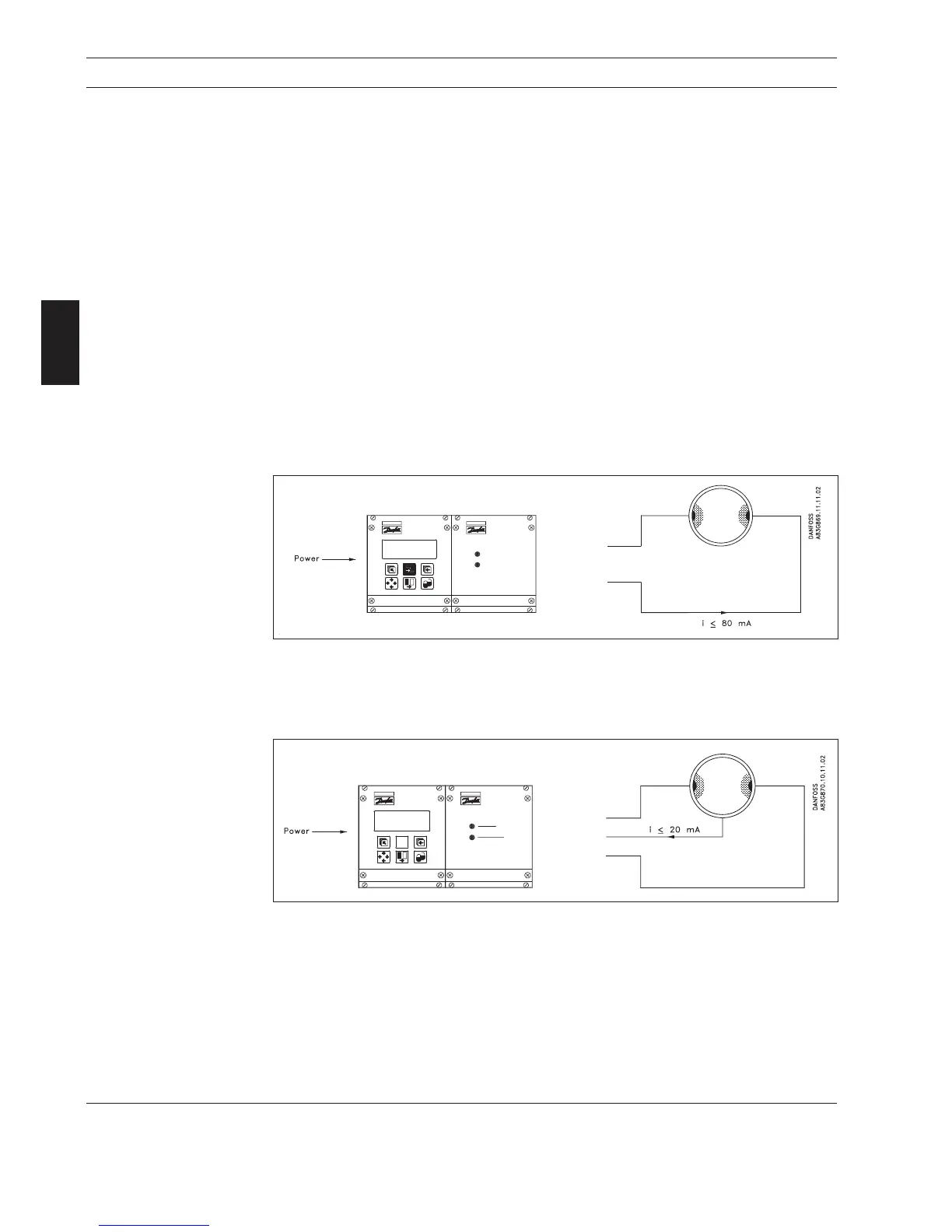

AC-cleaning

(For non-conductive coatings)

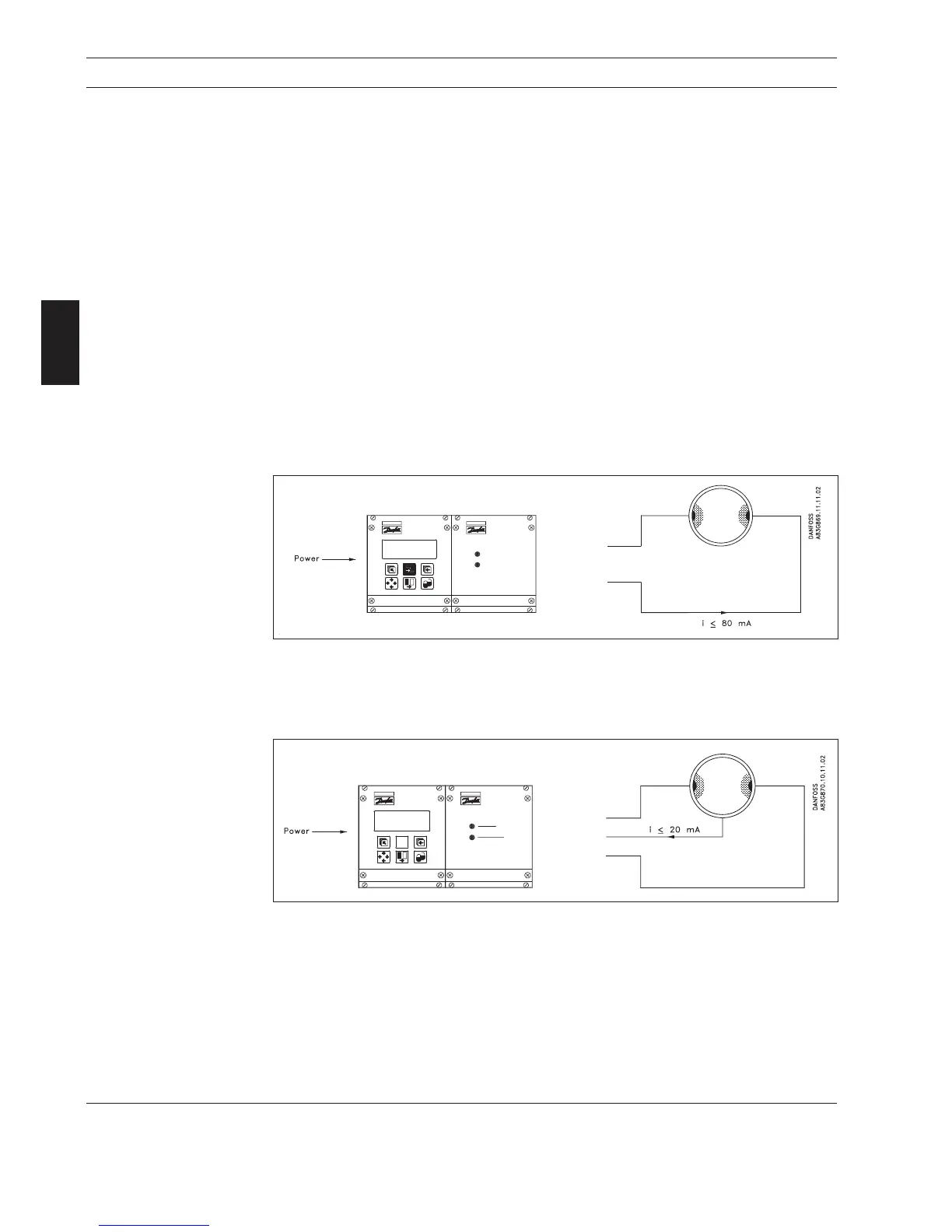

DC-cleaning

(For conductive coatings)

AC-cleaning is used to remove fatty deposits on the electrodes. Fatty deposits are seen from

Slaughter houses and in rare instances from wastewater applications and water applications with

oil residuals. During the cleaning process, the surface of the electrodes get warmer, which tends

to soften grease particles and the gas bubbles generated mechanically lift deposits away from the

surface of the electrodes.

DC-cleaning is used to eliminate electrically conductive deposits in the measuring pipe influencing

the measuring accuracy.

Particularly in district heating applications, an electrically conductive deposit (magnetite) may occur

and short-circuit the electrode signal. In this case the accuracy of the meter decreases and the signal/

noise conditions of the meter become inferior. The problem only arises if the conductivity of the water

is less than approx. 250 mS/cm.

During DC-cleaning, electrolysis takes place where the flow of electrons removes the particle

deposits from the electrode area.

Loading...

Loading...