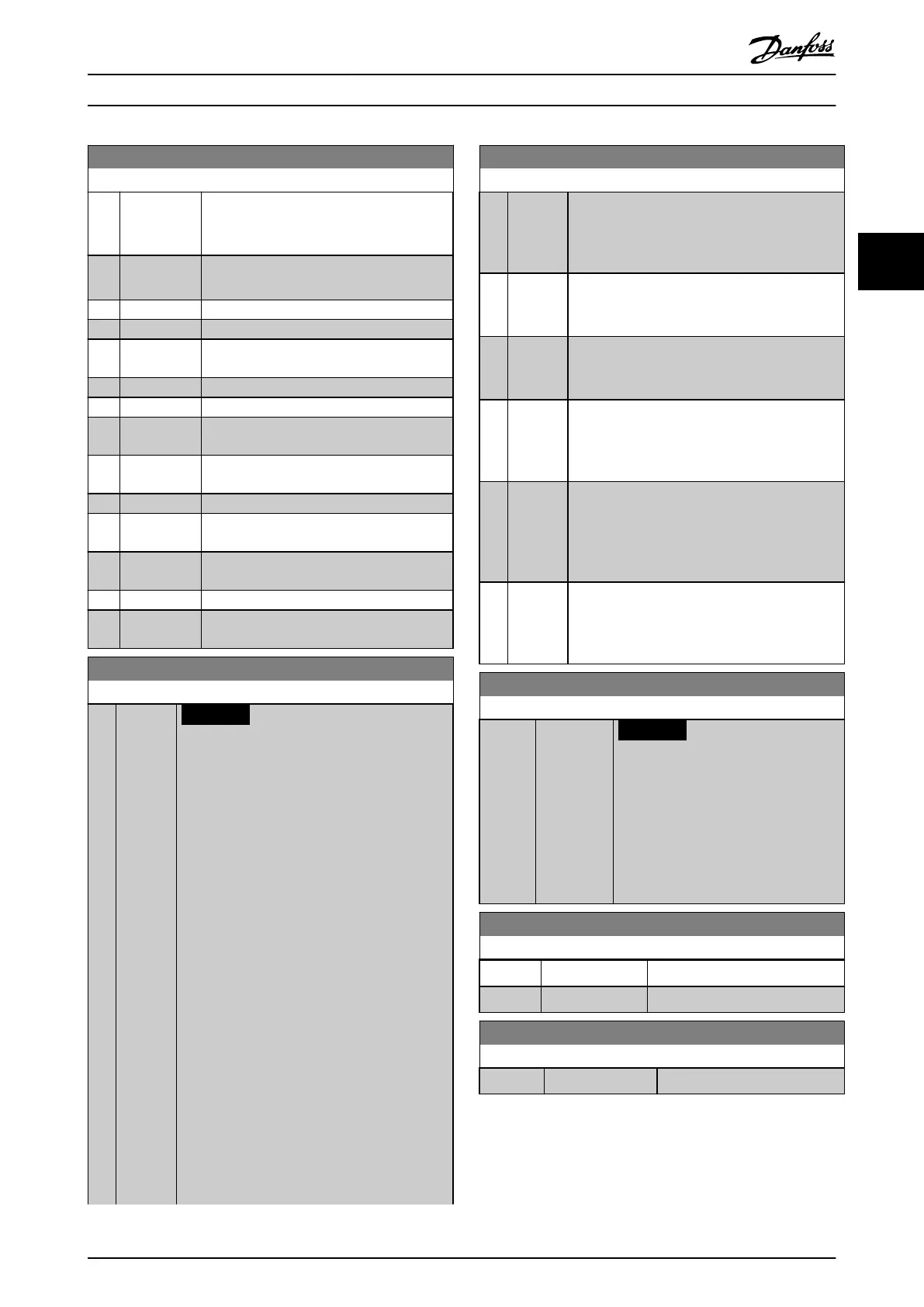

2-13 Brake Power Monitoring

Option: Function:

[2] Trip 120s Trips the frequency converter and shows an

alarm when the calculated power exceeds

100% of the monitoring limit.

[3] Warning &

trip 120s

Activates both of the above, including

warning, trip, and alarm.

[4] Warning 30s

[5] Trip 30s

[6] Warning &

trip 30s

[7] Warning 60s

[8] Trip 60s

[9] Warning &

trip 60s

[10] Warning

300s

[11] Trip 300s

[12] Warning &

trip 300s

[13] Warning

600s

[14] Trip 600s

[15] Warning &

trip 600s

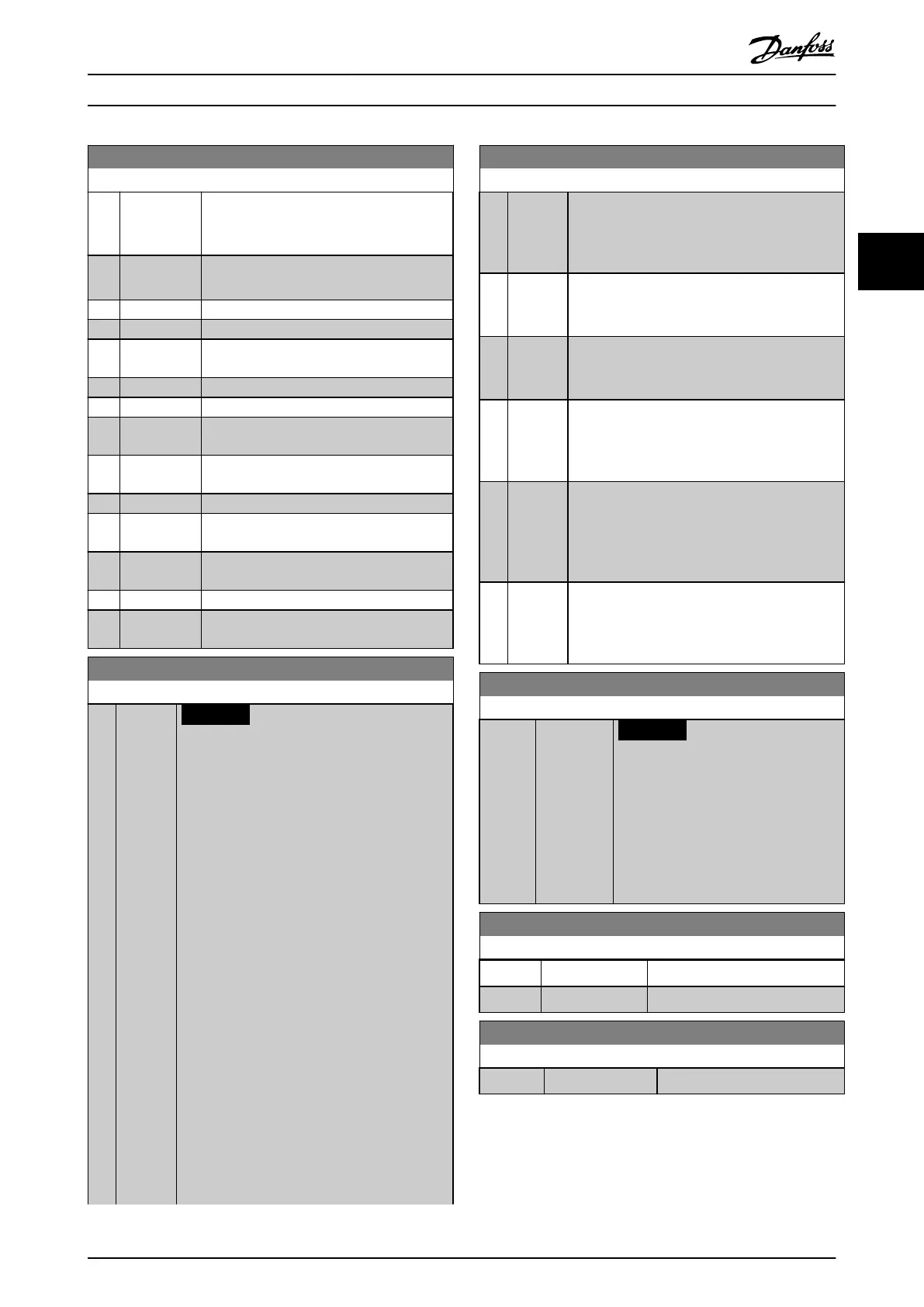

2-15 Brake Check

Option: Function:

NOTICE

Remove a warning arising with [0] O or

[1] Warning by cycling the mains supply.

Correct the fault rst. For [0] O or [1]

Warning, the frequency converter keeps

running even if a fault is found.

Select the type of test and monitoring function

to check the connection to the brake resistor, or

whether a brake resistor is present, and then

show a warning or an alarm if a fault occurs. The

brake resistor disconnection function is tested

during power-up. However, the brake IGBT test is

performed when there is no braking. A warning

or trip disconnects the brake function.

The testing sequence is as follows:

1. Measure the DC-link ripple amplitude

for 300 ms without braking.

2. Measure the DC-link ripple amplitude

for 300 ms with the brake turned on.

3. If the DC-link ripple amplitude while

braking is lower than the DC-link ripple

amplitude before braking +1%, the

brake check fails. If brake check fails, a

warning or alarm is returned.

2-15 Brake Check

Option: Function:

4. If the DC-link ripple amplitude while

braking is higher than the DC-link ripple

amplitude before braking +1%, the

brake check is OK.

[0]

*

O Monitors brake resistor and brake IGBT for a

short circuit during operation. If a short circuit

occurs, a warning appears.

[1] Warning Monitors brake resistor and brake IGBT for a

short circuit and runs a test for brake resistor

disconnection during power-up.

[2] Trip Monitors for a short circuit or disconnection of

the brake resistor, or a short circuit of the brake

IGBT. If a fault occurs, the frequency converter

cuts out while showing an alarm (trip lock).

[3] Stop and

trip

Monitors for a short circuit or disconnection of

the brake resistor, or a short circuit of the brake

IGBT. If a fault occurs, the frequency converter

ramps down to coast and then trips. A trip lock

alarm is shown.

[4] AC brake Monitors for a short circuit or disconnection of

the brake resistor, or a short circuit of the brake

IGBT. If a fault occurs, the frequency converter

performs a controlled ramp down.

2-16 AC brake Max. Current

Range: Function:

100.0 %* [0.0 -

1000.0 %]

NOTICE

Parameter 2-16 AC brake Max.

Current is not eective when

parameter 1-10 Motor Construction

= [1] PM, non-salient SPM.

Enter the maximum allowed current

when using AC braking to avoid

overheating of motor windings.

2-17 Over-voltage Control

Option: Function:

[0] Disabled No OVC required.

[2] * Enabled Activates OVC.

2-19 Over-voltage Gain

Range: Function:

100 %* [10 - 200 %] Select overvoltage gain.

Parameter Description Programming Guide

MG20OB02 Danfoss A/S © 05/2018 All rights reserved. 65

3 3

Loading...

Loading...