18

I-Class Mark II Maintenance Manual

Ad

ustments and Maintenance

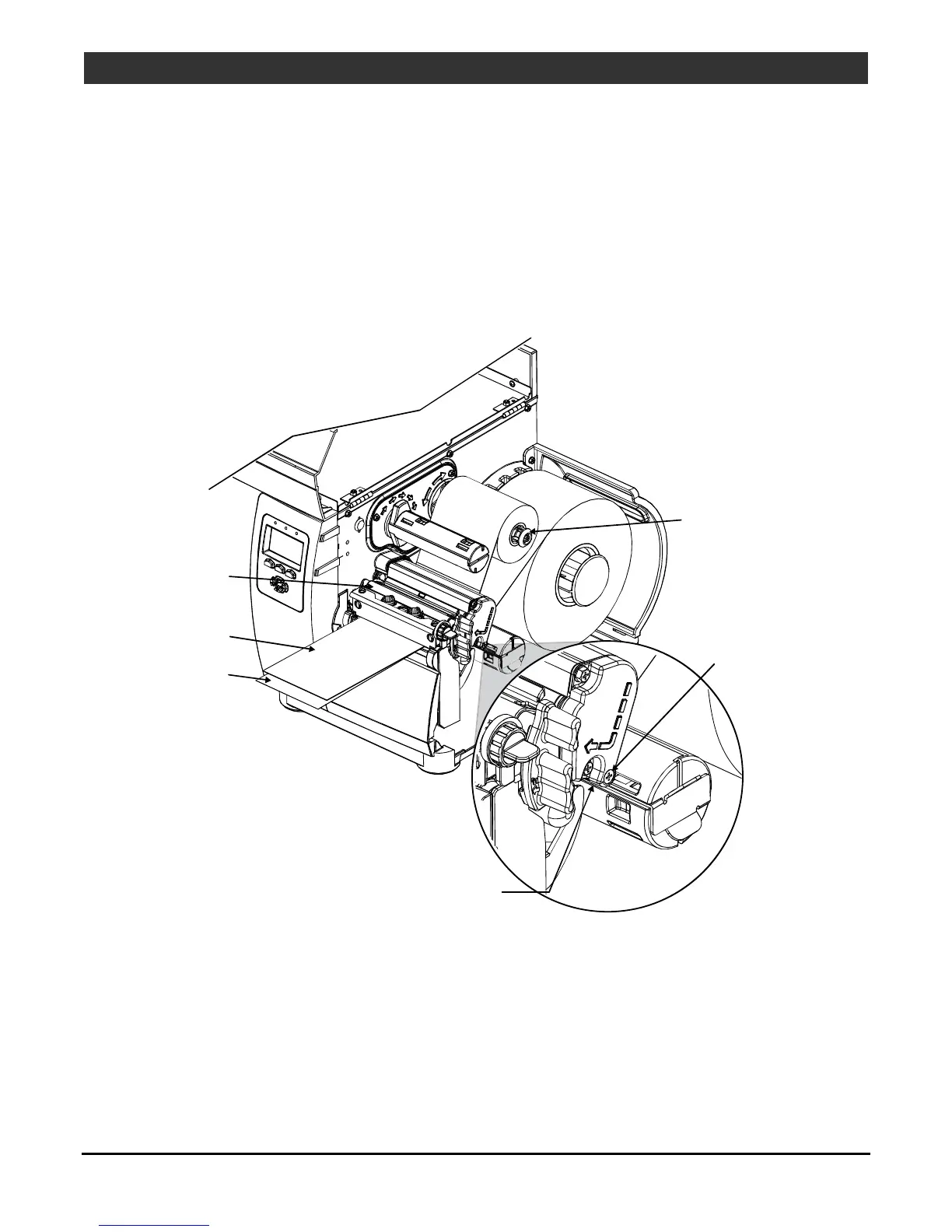

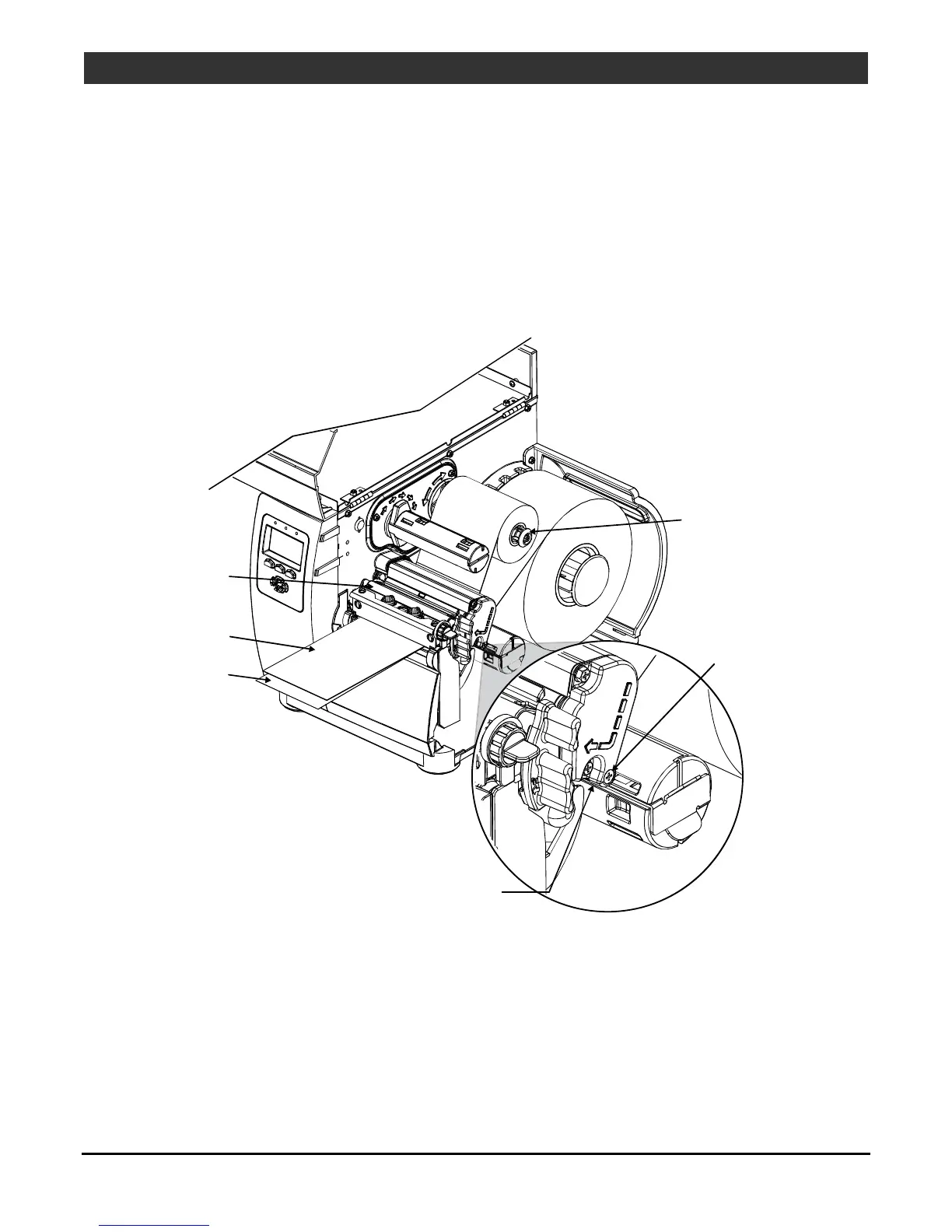

2.3 Ribbon Path Alignment

If irregular voids extend intermittently, diagonally through an image printed with ribbon, the cause may be

due to ribbon overlap (wrinkling). However, other factors can be involved. Begin troubleshooting by verifying

correct adjustment of the Leveling Cam (Section 2.2.1), Printhead Pressure (Section 2.2.2), and Burn Line

(Section 2.2.3). Also, examine the platen for wear, debris buildup, and excessive lateral movement. If all of

these adjustments and components are in good order, then perform a Ribbon Path Alignment as follows:

1. Load 4 inch (102mm) or wider Media.

2. Load a matching Ribbon and allow it to feed with the Media from the printer.

Ribbon

Supply Hub

Printhead

Assembly

Ribbon

Media

Idler Cam

Idler Scre

3. Disengage the Leveling Cam; see Section 2.2.1.

4. Plug in and turn ON the printer. Press FEED several times to normalize ribbon and label tracking. (If

lateral movement is excessive, this must be corrected before proceeding-- typical causes include an

unlatched printhead, uneven printhead pressure, a worn platen or worn platen bearings.)

5. Observe the ribbon for rippling and bagging as it travels from the Ribbon Supply Hub to the Printhead

Assembly. If smooth, proceed to Step 6; otherwise, loosen the Idler Screw then, while repeatedly pressing

FEED, rotate the Idler Cam until the ribbon is smoothly dispensed. Tighten the Idler Screw and feed

several more labels to verify adjustment; repeat if necessary.

Loading...

Loading...