V0817, 8.24

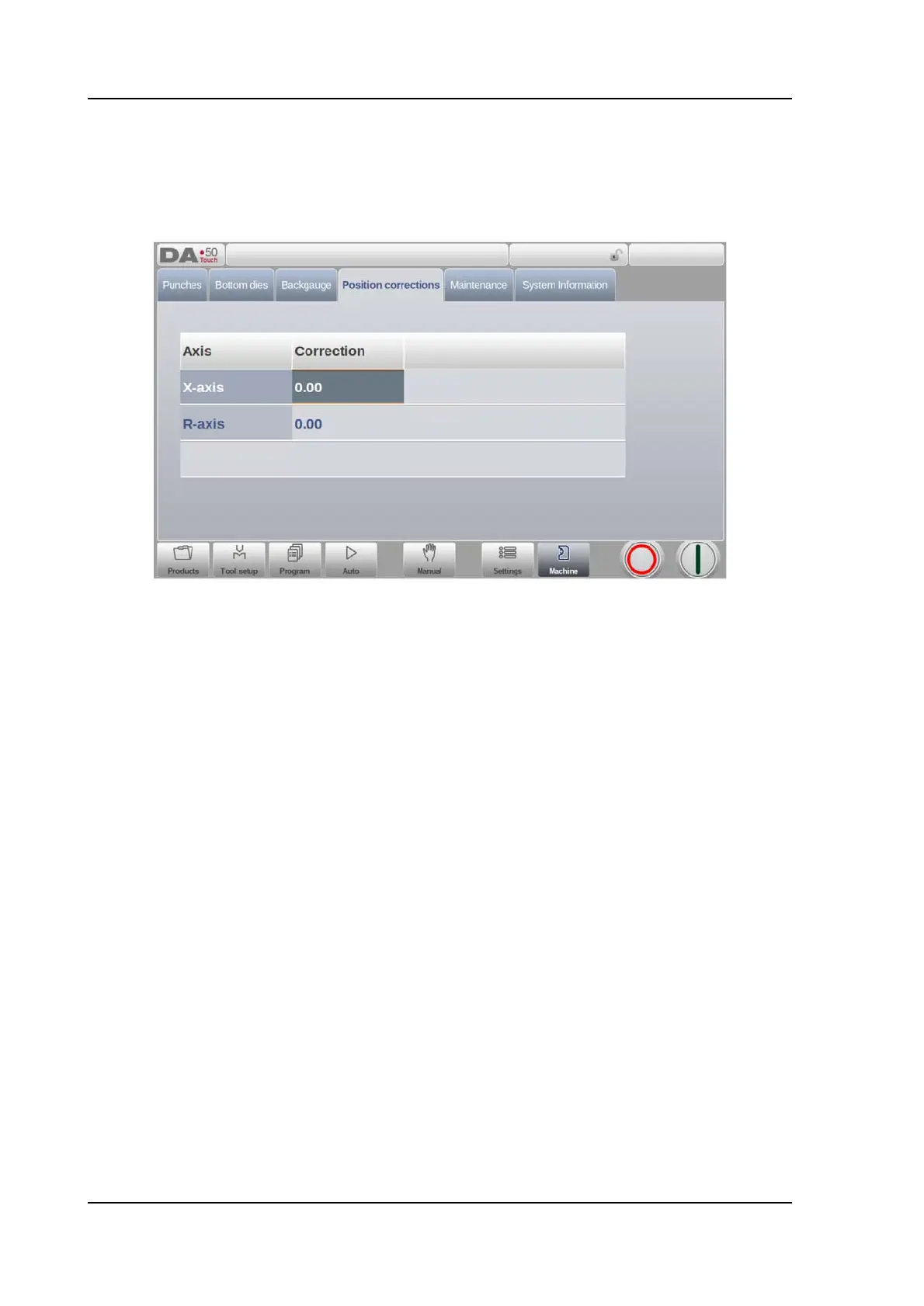

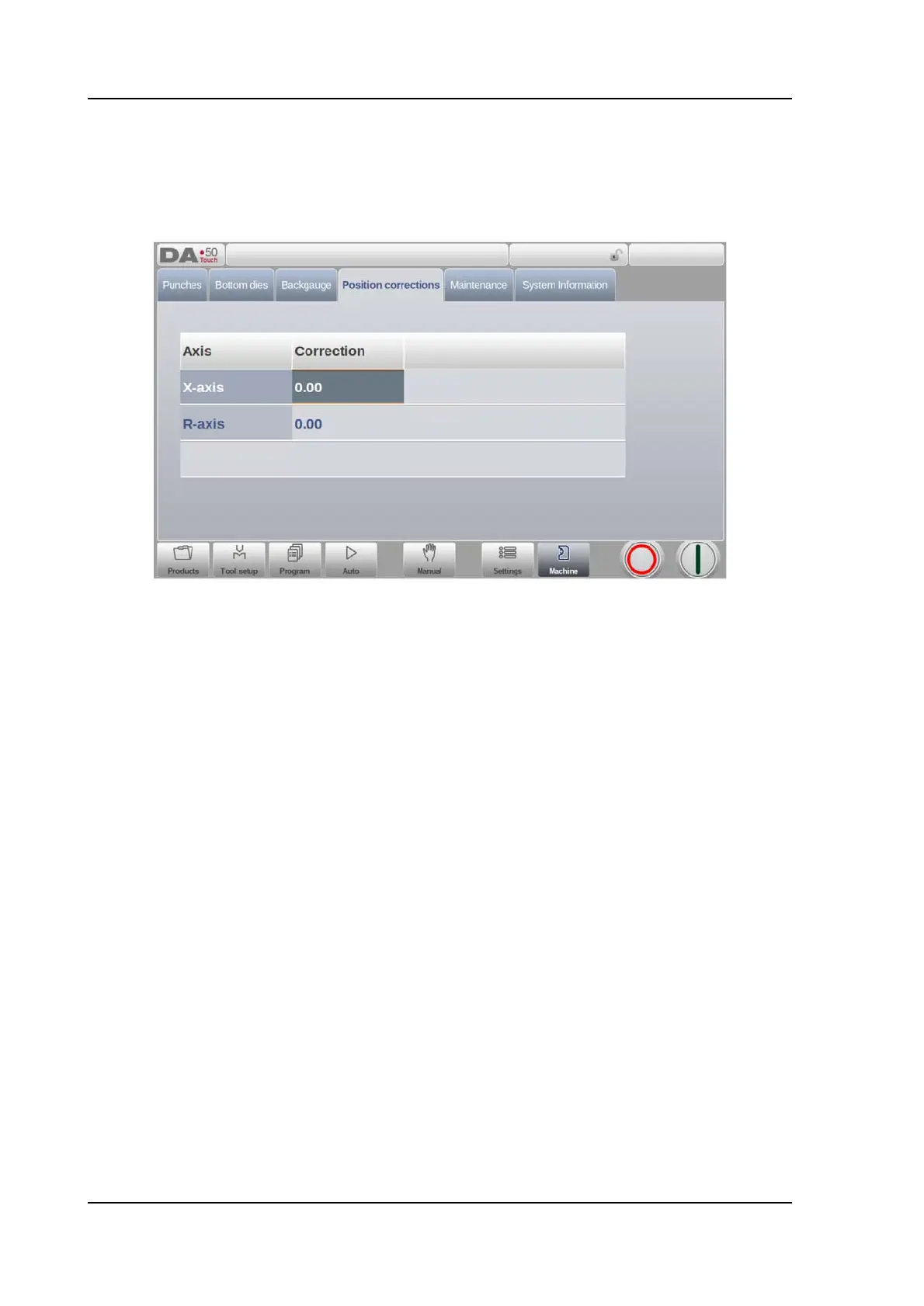

8.5. Position corrections

Position correction

When the actual, mechanical axis position is not corresponding with the displayed value

it is possible to correct the position with this parameter. Program the calculated

difference.

Example:

- When the programmed and displayed value = 250 and the actual, mechanical position

value = 252 the correction parameter = -2.

- When the programmed and displayed value = 250 and the actual, mechanical position

value = 248 the correction parameter = +2.

Position corrections are available for all auxliliary axes.

Position corrections should only be used temporarily. In case machine positions have

changed after commisioning or service, positions of axes can be corrected. In normal

situations these corrections should be 0.

Loading...

Loading...