2) Inspection of cylinder head

(1) Check for the cylinder head.

Remove carbon from the cylinder head lower surface,

and then should be careful not to scratch the surface.

Check any crack or damage that can not found by

naked eyes through the hydraulic or magnetic particle

test.

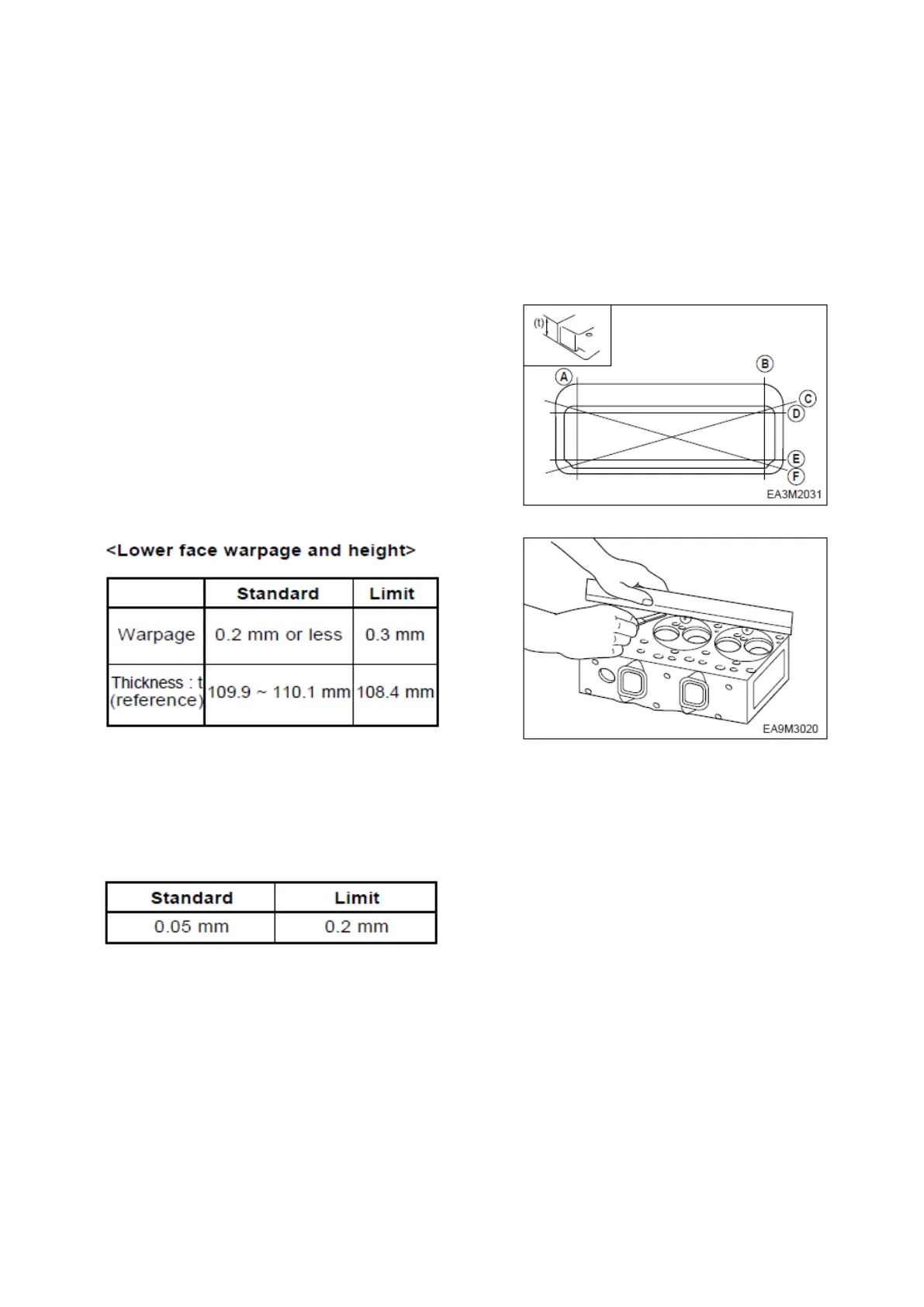

(2) Distortion of lower surface

As shown in figure, measure the cylinder head‘s

distortion at 6 directions with horizontal ruler and

clearance gauge.

If the measured value is beyond the limit value, correct

it by means of the fine grinding paper or grinding

machine.

If it is beyond the max. allowable value, replace the

cylinder head.

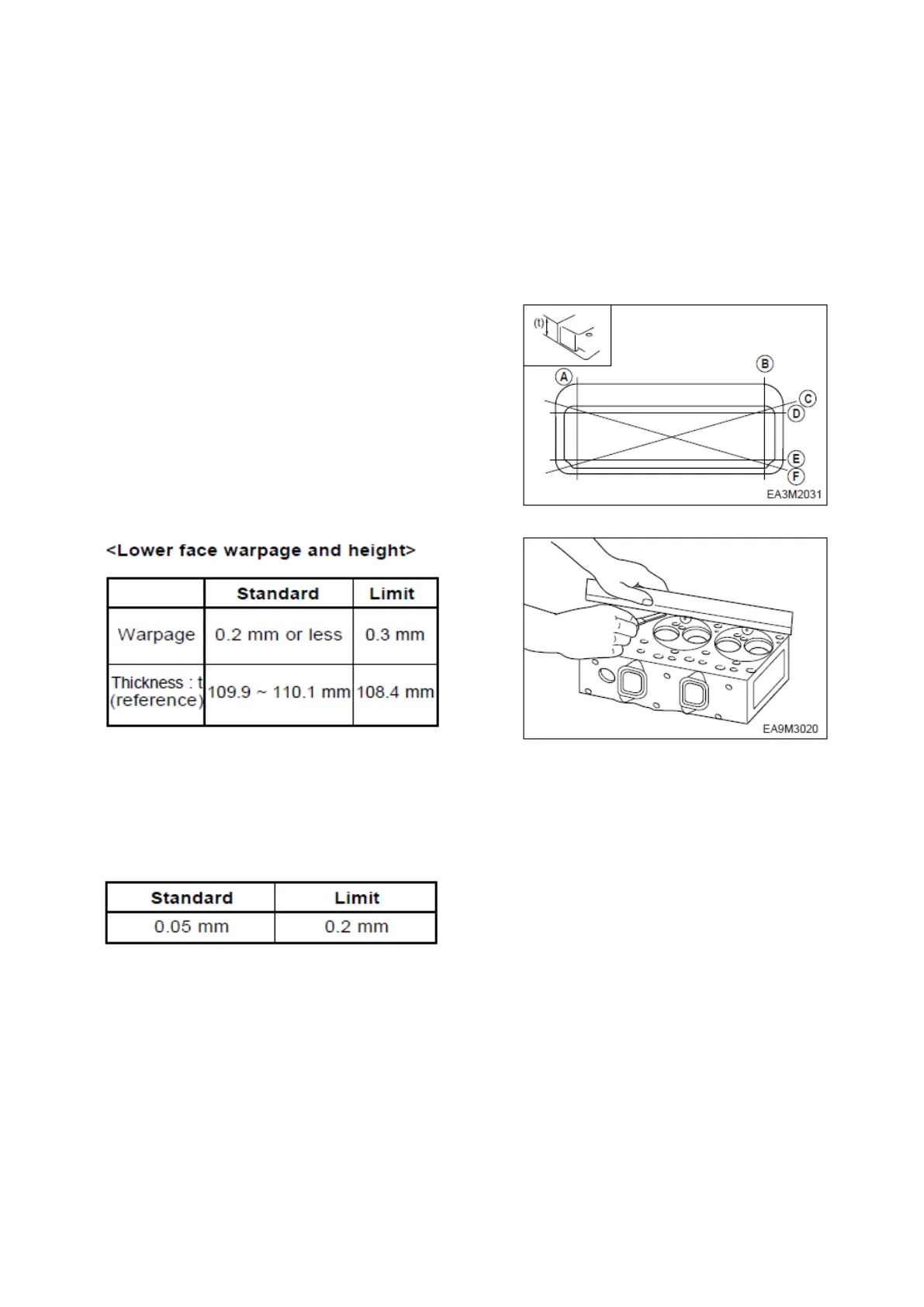

(3) Flatness

Check the flatness of the installing surface of cylinder

head‘s intake and exhaust manifolds with horizontal ruler

and clearance gauge.

(4) The hydraulic test

The hydraulic test of cylinder head is same as the

cylinder block test.

SPC000006 5ton Diesel Engine

Page 46

Loading...

Loading...