<Undersize bearings available>

Standard

0.25 (Inside diameter is 0.25 mm lesser than the standard size.)

0.50 (Inside diameter is 0.50 mm lesser than the standard size.)

0.75 (Inside diameter is 0.75 mm lesser than the standard size.)

1.00 (Inside diameter is 1.00 mm lesser than the standard size.)

Undersize bearings are available in 4 different sizes as indicated above, and the crankshaft can be reused

through the regrinding as described above.

Caution:

In case of regrinding, the grinding the “R” part of bearing end should be correctly done and keep

in mind to remove any jaws or coarse surface absolutely.

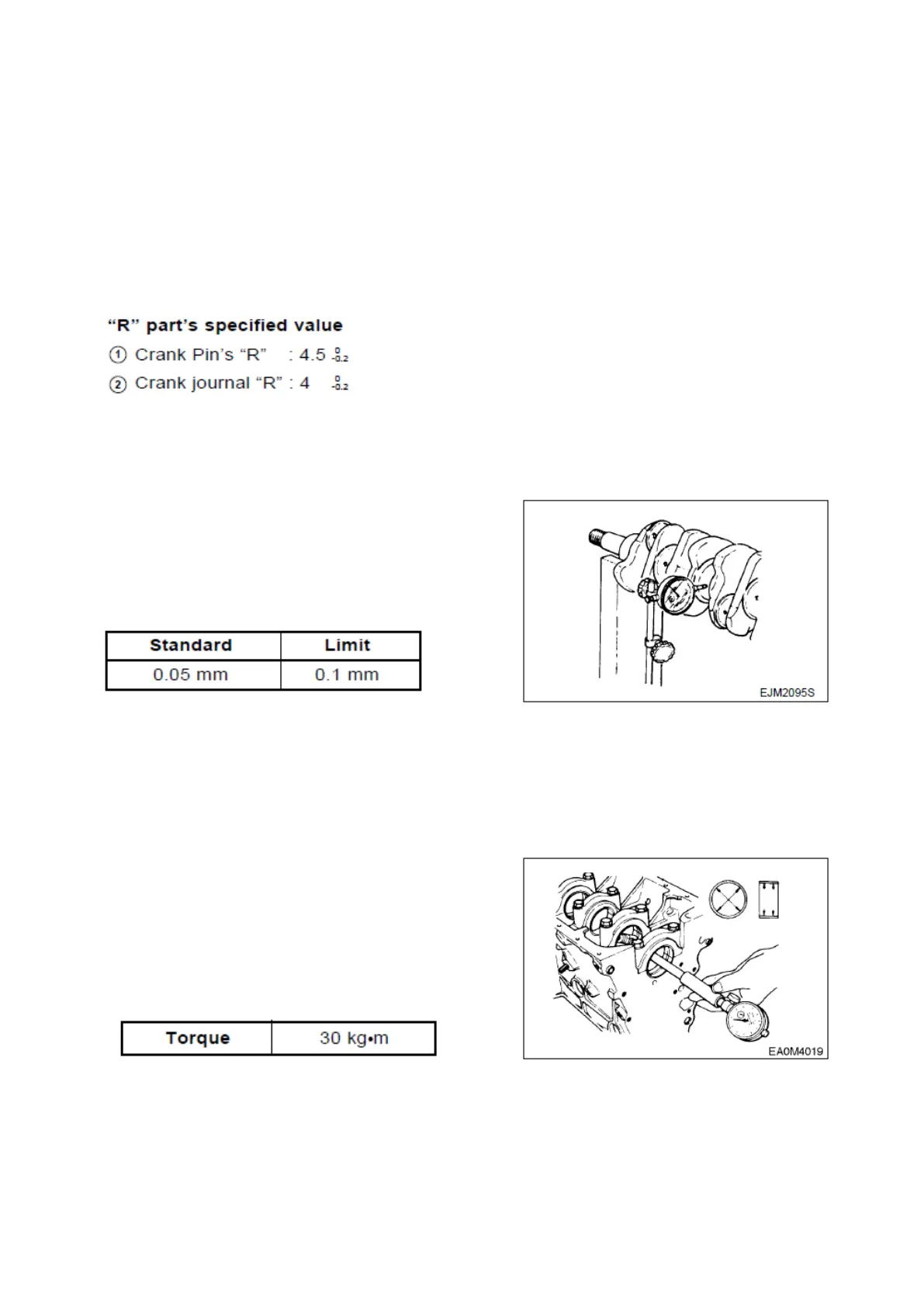

(3) Crankshaft run-out

Support the crankshaft on V blocks.

Turn the crankshaft with a dial indicator placed on the

surface plate and take the amount of crankshaft run-out.

2) Crankshaft bearing and connecting rod

(1) Visual check

Visually check the crankshaft bearing and connecting

rod bearing for scores, uneven wear or damage.

(2) Oil clearance between crankshaft and bearing

(Method 1: dial gauge)

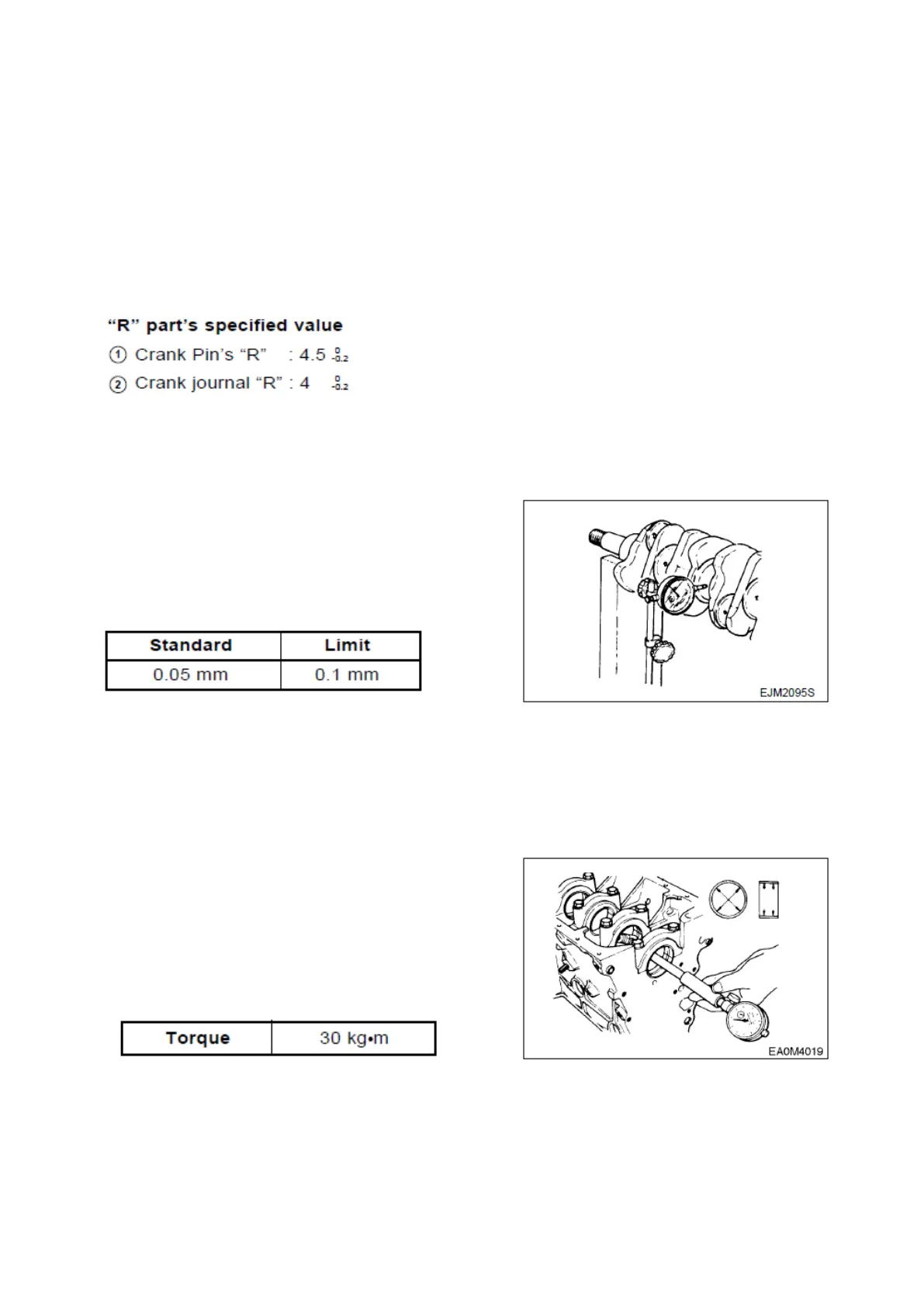

Main bearing clearance

Install the main bearing in the cylinder block, tighten

the bearing cap to specified torque, then measure the

inside diameter.

Compare the two values obtained through

measurement of main bearing inside diameter with the

SPC000006 5ton Diesel Engine

Page 56

Loading...

Loading...