WELDING REPAIRS

When carrying out welding repairs, carry out the welding in a properly equipped place. The welding should

be performed by a qualified worker. During welding operations, there is the danger of, generation of gas, fire,

or electric shock, so never let an unqualified worker do welding.

The qualified welder must do the following;

• To prevent explosion of the battery, disconnect the battery terminals and remove batteries.

• To prevent generation of gas, remove the paint from the location of the weld.

• If hydraulic equipment, piping or places close to them are heated, a flammable gas or mist will be

generated and there is danger of it catching fire. To avoid this, never subject these places to heat.

• Do not weld on pipes or on tubes that contain flammable fluids. Do not flame cut on pipes or on tubes

that contain flammable fluids. Before you weld on pipes or on tubes or before you flame cut on pipes or

on tubes, clean the pipes or tubes thoroughly with a nonflammable solvent.

• If heat is applied directly to rubber hoses or piping under pressure, they may suddenly break so cover

them with a fireproof covering.

• Wear protective clothing.

• Make sure there is good ventilation.

• Remove all flammable objects and provide a fire extinguisher.

PRECAUTIONS FOR REMOVAL, INSTALLATION,

AND STORAGE OFATTACHMENTS

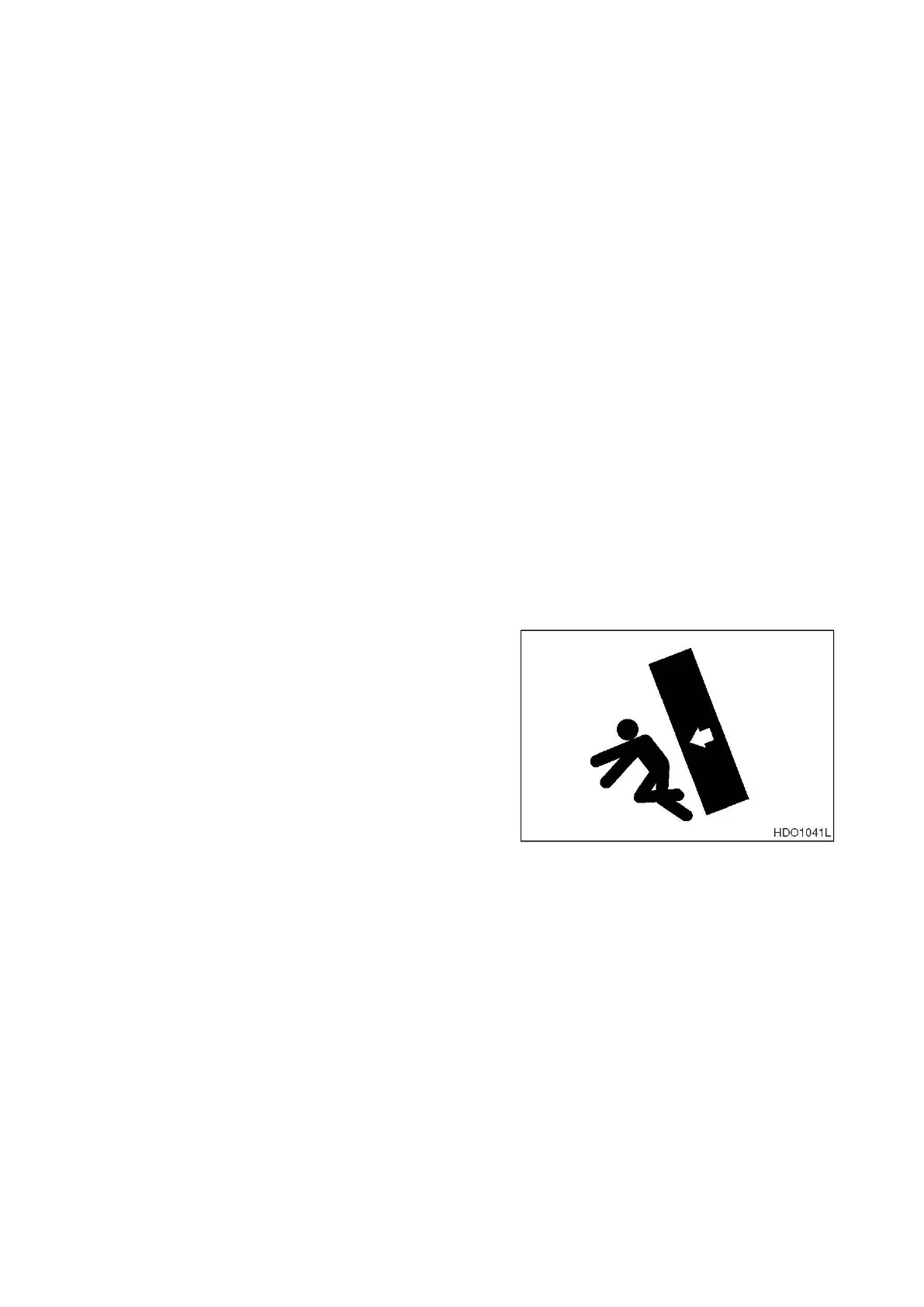

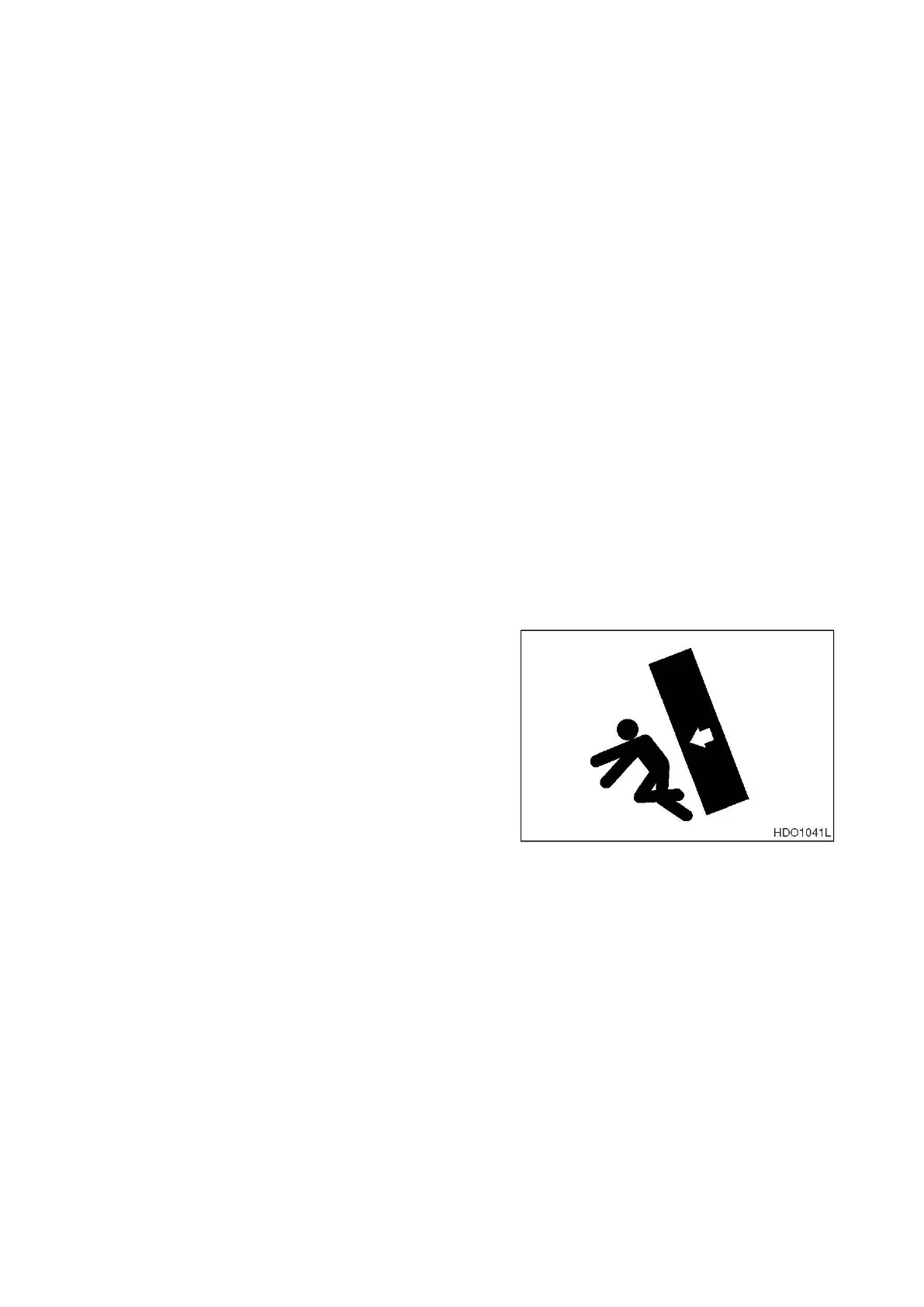

Before starting removal and installation of

attachments, decide the team leader.

Do not allow anyone except the authorized workers

close to the machine or attachment.

Place attachments that have been removed from

the machine in a safe place so that they do not fall.

Put up a fence around the attachments and take

other measures to prevent unauthorized persons

from entering.

Wheel Loader Safety S0103010K

Page 27

Loading...

Loading...