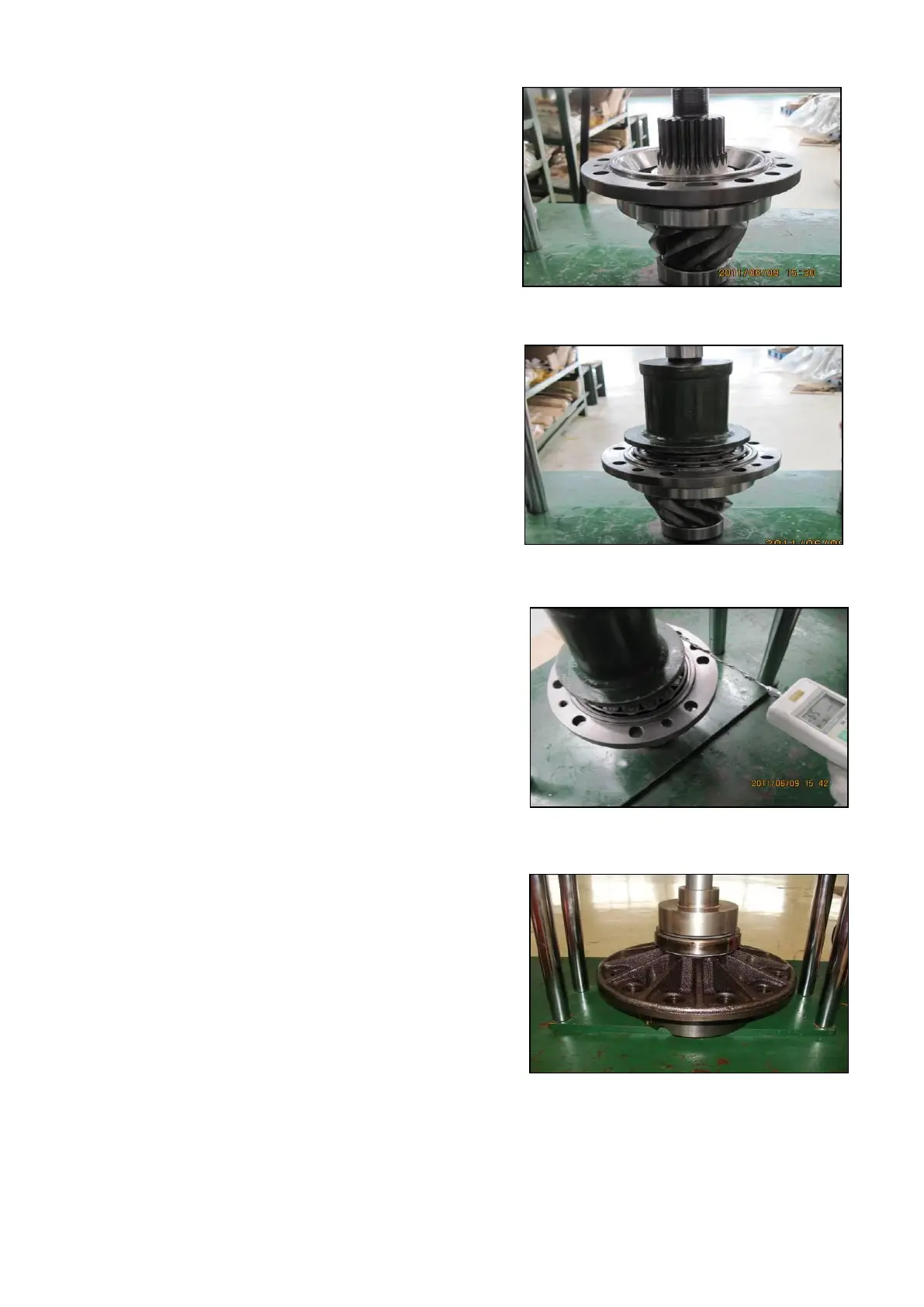

7. Install bearing sleeve

8. Press inner ring of antifriction bearing in the end.

Note: when assembling main reducer, taper rolling

bearing shall have certain tightness that is on the

basis of eliminating bearing clearance and give

certain preload. The purpose is to reduce axial force

caused during transmission process which will result

in axial displacement, improve supporting rigidity,

and guarantee normal mesh of bevel gear pair. But

if it is too tight, it will accelerate abrasion of taper

rolling bearing. Press with P= 5420 kg pressure at

the top side of inner ring of rolling bearing, grapple

Φ14.5 hole with pull and push ergometer, pull

ergometer along with tangential direction, indication

of ergometer when pushing shall be 17.34-30.06N,

if the indication is not within the range of 17.34-

30.06N, increase or reduce thickness of spacer

shim, repeat the above process until the indication

is within 17.34-30.06N.

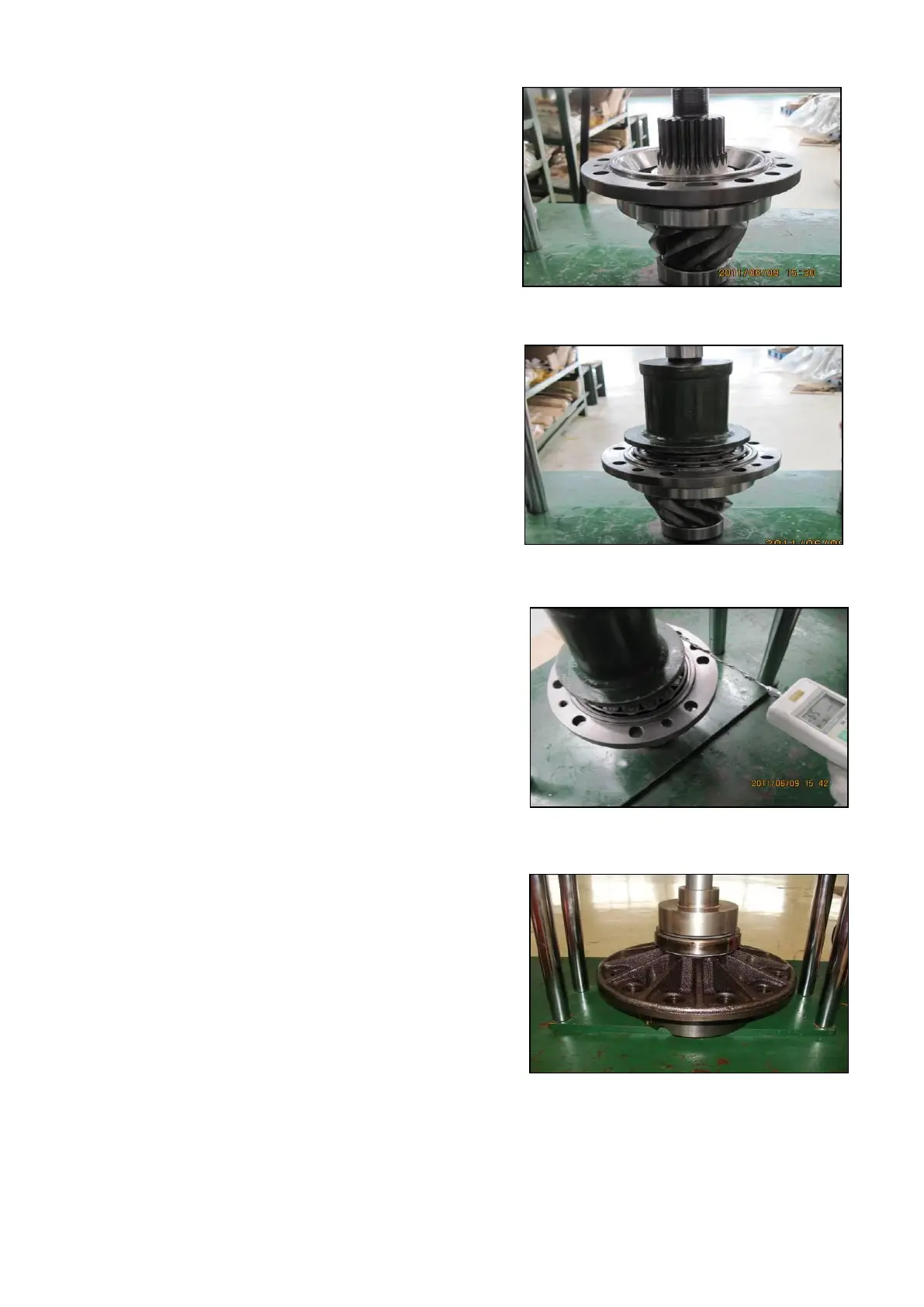

Assemble of differential assembly

2. Assemble rolling bearing at the bearing position of

right shell terminal of differential mechanism.

SPC000010 Rear Axle

Page 36

Loading...

Loading...