Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

User Menu A

Commissioning

Advanced

Parameters

Diagnostics Optimization CT MODBUS RTU Technical Data

E300 Design Guide 159

Issue Number: 1

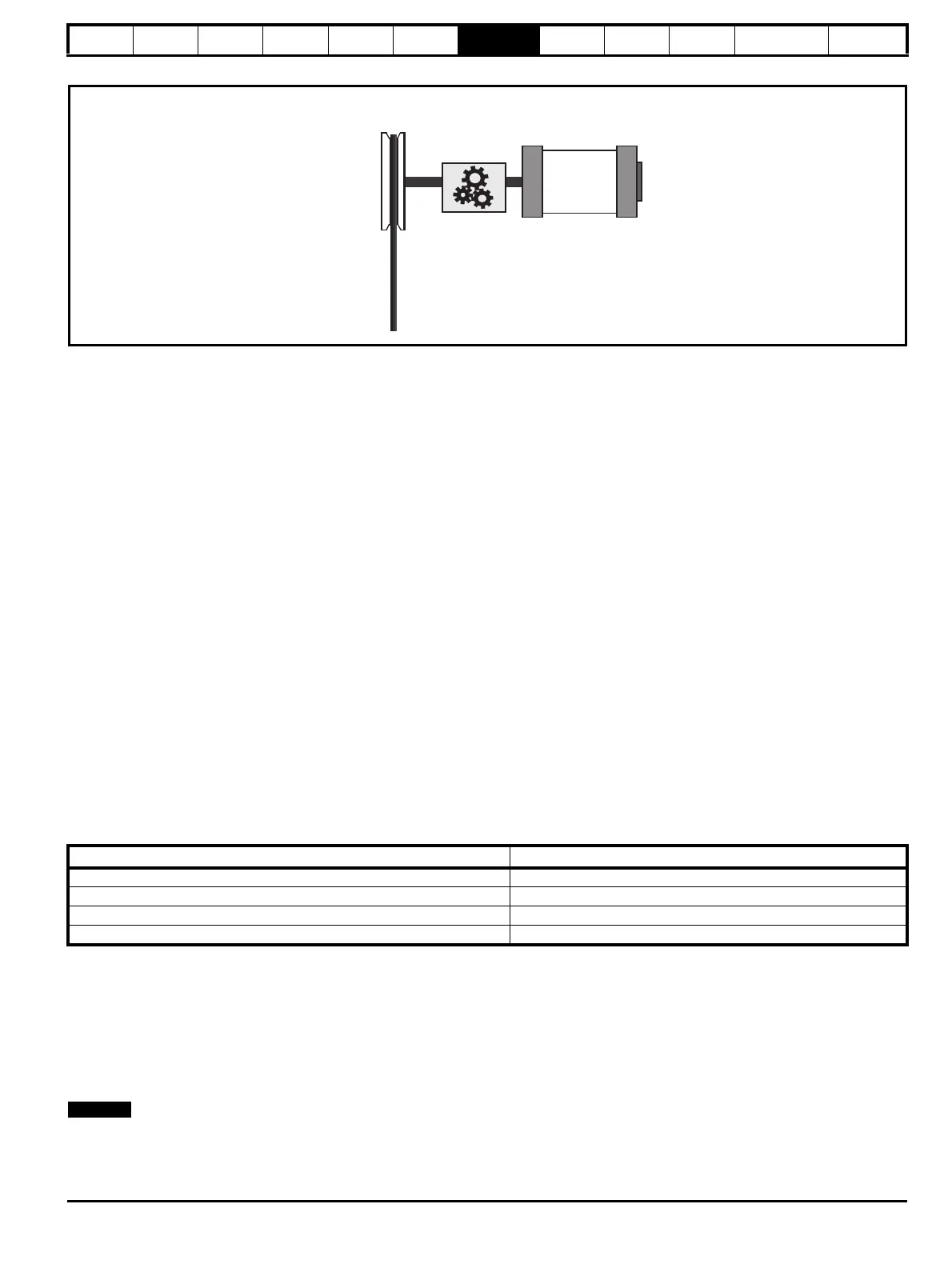

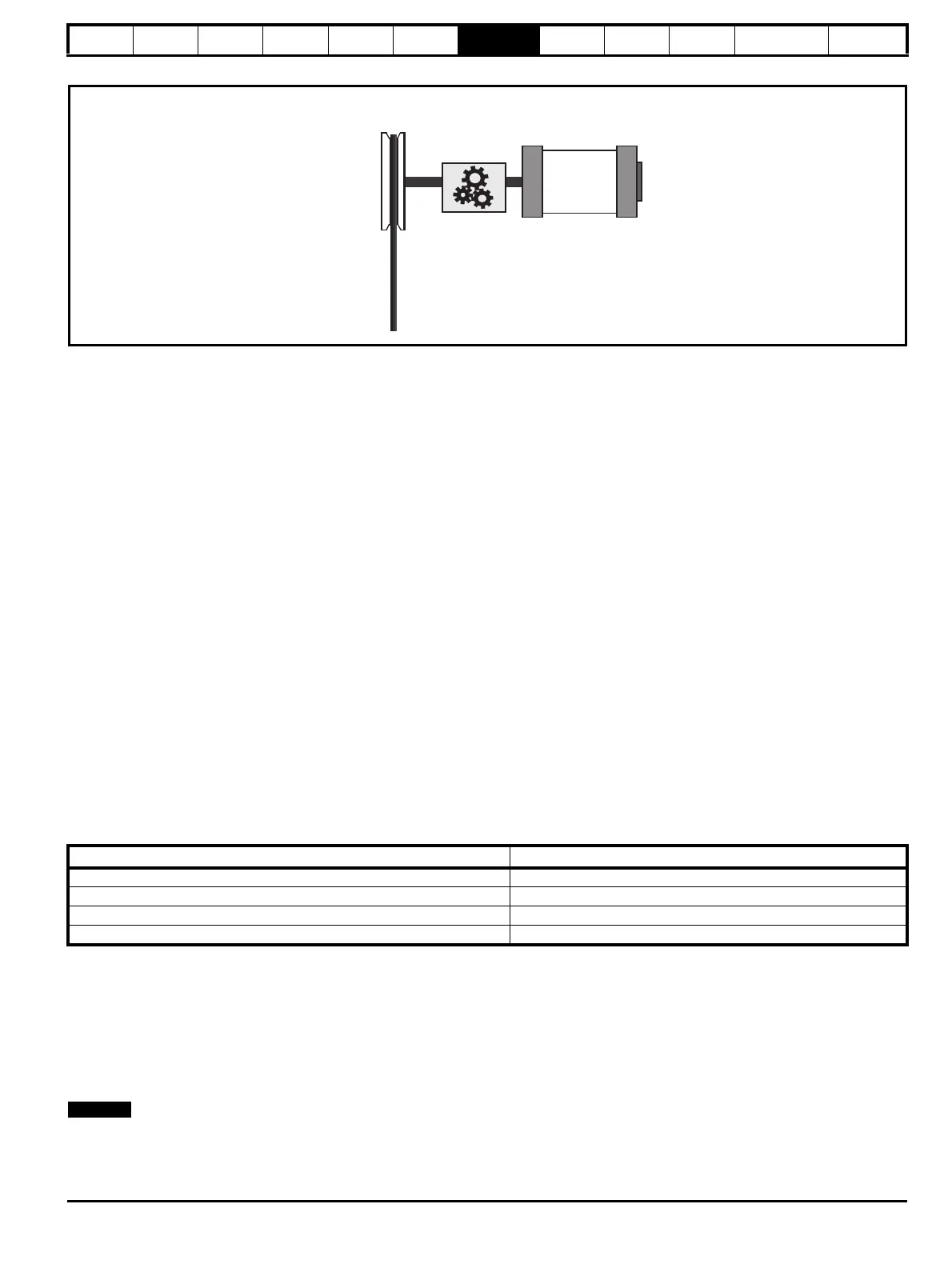

Figure 7-3 Elevator mechanical data

7.5 Creep to floor profile

The default operating mode for the E300 Advanced Elevator drive is Closed loop Servo for permanent magnet synchronous servo motors in gearless

Elevator systems with Creep to floor positioning. Positioning with Creep to floor is a commonly used operating mode.

For all sections of the profile shown below, there are independent parameters available for the Start optimization, Jerks, Acceleration, Deceleration

and Creep to floor which allow the ride comfort of the Elevator to be optimized.

For Creep to floor operation, the operating speed is selected according to the Elevator landing distance. The E300 Advanced Elevator drive by default

uses digital pre set speed selections set-up in V1 Creep Speed Reference (G01) to V4 Speed Reference (G04) as detailed below.

The Creep speed is configured to be V1 Creep Speed Reference (G01) the remaining speed selections V2, V3 and V4 can be configured for any

speed e.g Nominal speed, High speed, Low speed.

In addition to controlling the profile, the deceleration distance is also calculated in mm dependent upon the speed selected speed selected shown in

Reference Parameter Selected (J09)) and the profile settings. The calculated deceleration distance is displayed in Deceleration Distance Calculated

(J43) for the activated speed.

The measured deceleration distance is displayed after every travel in Deceleration Distance Measured (J44) in mm. The measured Creep speed

distance is also available and shown in Creep Distance Measured (J45).

The real-time demand on the Elevator control system is low with Creep to floor positioning with a typical cycle time of the Elevator controller of 5 to 20

ms and the E300 Advanced Elevator drive of 8 ms the minimal positioning distance with Creep to floor is calculated as follows:

The maximum Creep speed distance =

Positioning distance [mm]

≥ V

Nominal

[m/s] x 30 ms

The stop accuracy =

Accuracy [mm]

≤ V

Creep speed

[m/s] x 30 ms

The time required for the Creep speed =

Time Creep speed [ms] = positioning distance [mm] / V

Creep speed

[m/s]

Table 7-11 Elevator speeds and distances

The timing diagram in Figure 7-4 Creep to floor profile, Timing diagram on page 160, shows the sequence of operation in the Creep to floor mode as

is also detailed below:

• A start sequence is received at the drive from the Elevator controller by means of selecting both a speed and direction.

• Following selection of both the speed and direction inputs on the drive, the Elevator controller then closes the output motor contactors. On closing

the output motor contactors, the Safe Torque Off (STO) Drive enable is applied to the drive, and if the Fast disable is used this is also removed

and the drive’s output becomes active.

• Once enabled, the symmetrical drive current limit is ramped up and torque is generated to hold the motor at zero speed, also using the Start lock

position if active.

• With the drive holding the motor at zero speed the brake is opened and the profile started.

Following any system fault where a drive trip may occur, and the brake control is carried out by the drive, the brake is automatically closed and the

drive output disabled.

Speed selected Speed selected parameter

V1 Speed Reference (creep speed by default) G01

V2 Speed Reference G02

V3 Speed Reference G03

V4 Speed Reference G04

Elevator

motor

Elevator

gearbox

Elevator

sheave

Elevator

roping

A Nominal elevator

speed (motor) rpm

B Nominal elevator

speed mm/s

C Sheave

diameter

D Roping

E Gear ratio

numerator

F Gear ratio

denominator

Loading...

Loading...