Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

User Menu A

Commissioning

Advanced

Parameters

Diagnostics Optimization CT MODBUS RTU Technical Data

162 E300 Design Guide

Issue Number: 1

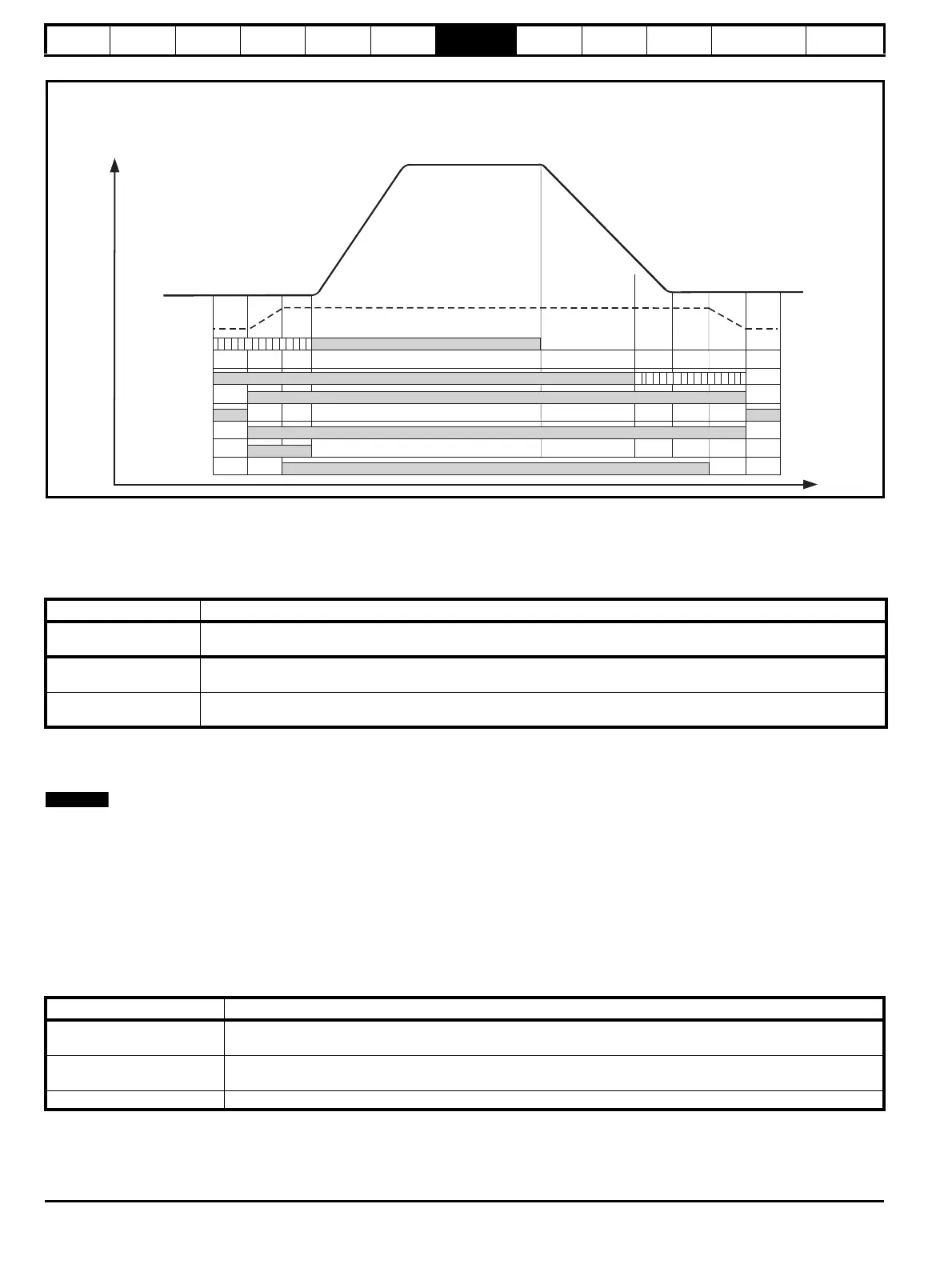

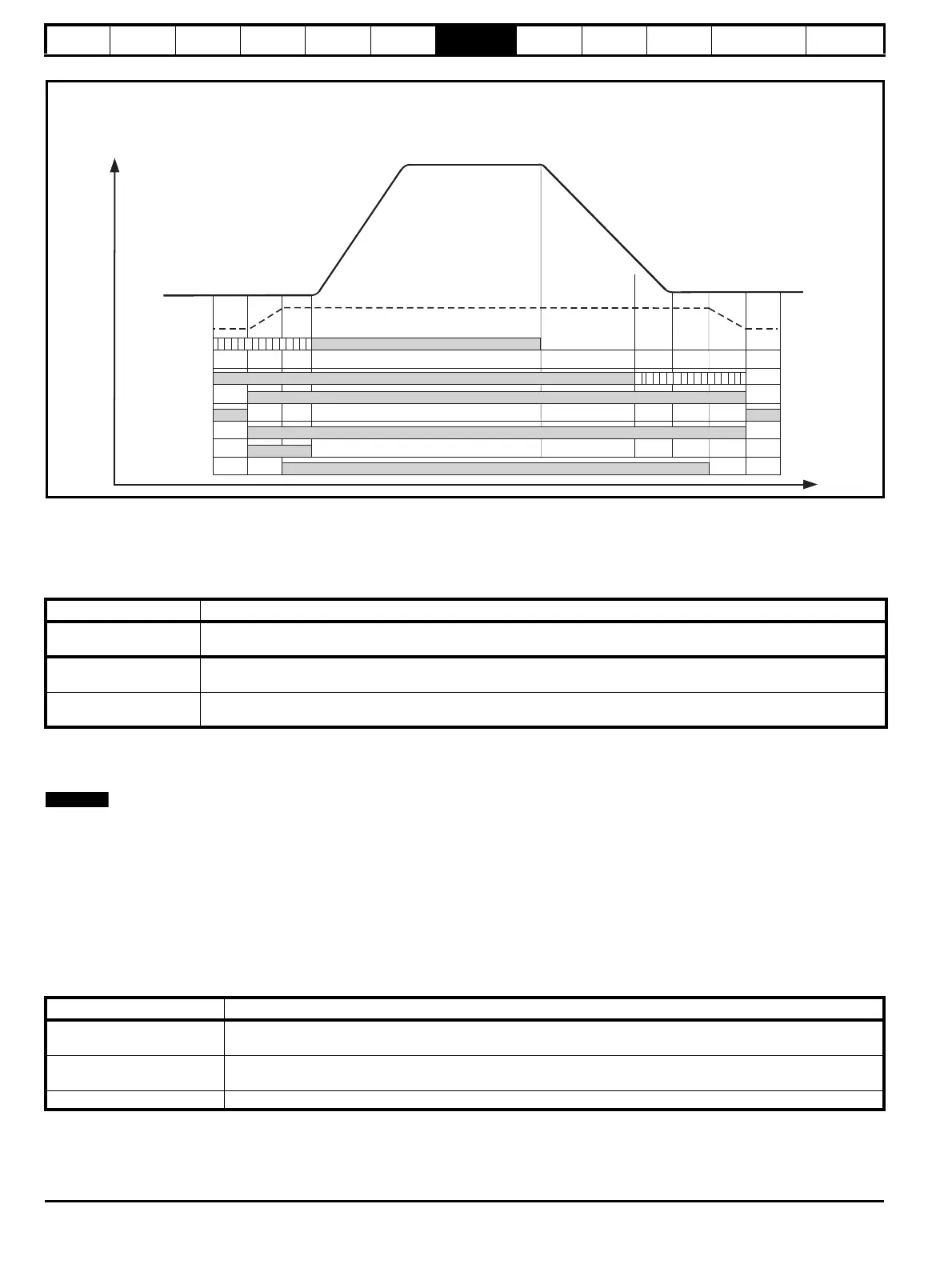

Figure 7-7 Direct to floor profile, timing diagram

7.7 Creep to floor / Direct to floor - Start

For geared and gearless Elevator applications operating in Creep to floor mode / Direct to floor mode, the start performance can be optimized using

the following procedure. For open loop operation only the start optimizer is available.

Table 7-15 Start set-up control

7.7.1 Start lock on brake release control

The start lock uses a position controller for the start and can be used to prevent roll back on brake release. The start lock holds the Elevator car in

position following Drive enable and opening of the brake. Once the profile is started the start lock position control is disabled.

The start lock position control is only available for Closed loop operation, and is by default disabled.

Closed loop operation

Start locking is independent of the start speed loop gains, and may be required where increased start speed loop gains are not possible due to

instability associated with low resolution speed feedback devices or acoustic noise from the motor.

The maximum values for the start lock Kp gain will be limited by the settings of the active start speed loop gains. Under normal operation, the variable

speed loop gains alone should be sufficient to hold the motor during brake release and prevent rollback. Therefore the start speed loop gains should

be optimized before enabling the start lock position control.

If "STOP" is displayed on the keypad, the position controller does not operate as no speed has been selected and the motor’s brake is closed.

Table 7-16 Start lock position control parameters

Feature Details

Speed control loop gains

For Closed loop operation the Start Speed Loop P Gain (I01) and Start Speed Loop I Gain (I02) gains can be used for

optimization

Start lock

A start lock position control is available for Closed loop operation and used in addition to the start speed loop gains. This

control is mainly used in gearless applications where high start speed loop gains may not possible.

Start optimizer

The start optimizer is available for both Open and Closed loop operation with either geared or gearless Elevators. The

start optimizer is mainly used to overcome mechanical imperfections in the system.

Parameter Details

Start Lock P Gain (I20)

Setting to > 0 results in the Elevator car being held in position during brake release. The maximum detectable

position error is determined by the level of proportional gain.

Start Lock P Gain Speed

Clamp (I21)

Speed clamp, defines the rate of change of correction for the start locking. Default value is suitable for most

applications.

Start Lock Enable (I22) Enable, disable start lock position.

Drive active

Direction

FAST disable

STO, Drive enable

Start lock

Speed selection

Torque producing current

Debounce motor contac

tors (100 ms)

Brake Control Apply Delay ( )D05

Interlock delay (> 50 ms)

Control terminal 26

Run Jerk 1 ()G13

Run Jerk 2 ()G14

V1 Speed Reference ()G01

V10 ()G10Speed Reference

Ramp torque (100 ms)

Ramp torque (100 ms)

Control terminal 7 (V2), 26 (V3), 5 (V4)

Control terminal 28

Control terminal 31

Drive active, L06

Brake output

Control terminal 25

Start lock position Kp, 120

External motor contactor control

External motor contactor control

Run Jerk 3 ()G15

Brake Control Release Delay ()D04

Acceleration Rate

()G11

Deceleration Rate

()G12

Run Jerk 4 ()G16

Brake Control Apply Delay ()D05

Loading...

Loading...