Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

User Menu A

Commissioning

Advanced

Parameters

Diagnostics Optimization CT MODBUS RTU Technical Data

168 E300 Design Guide

Issue Number: 1

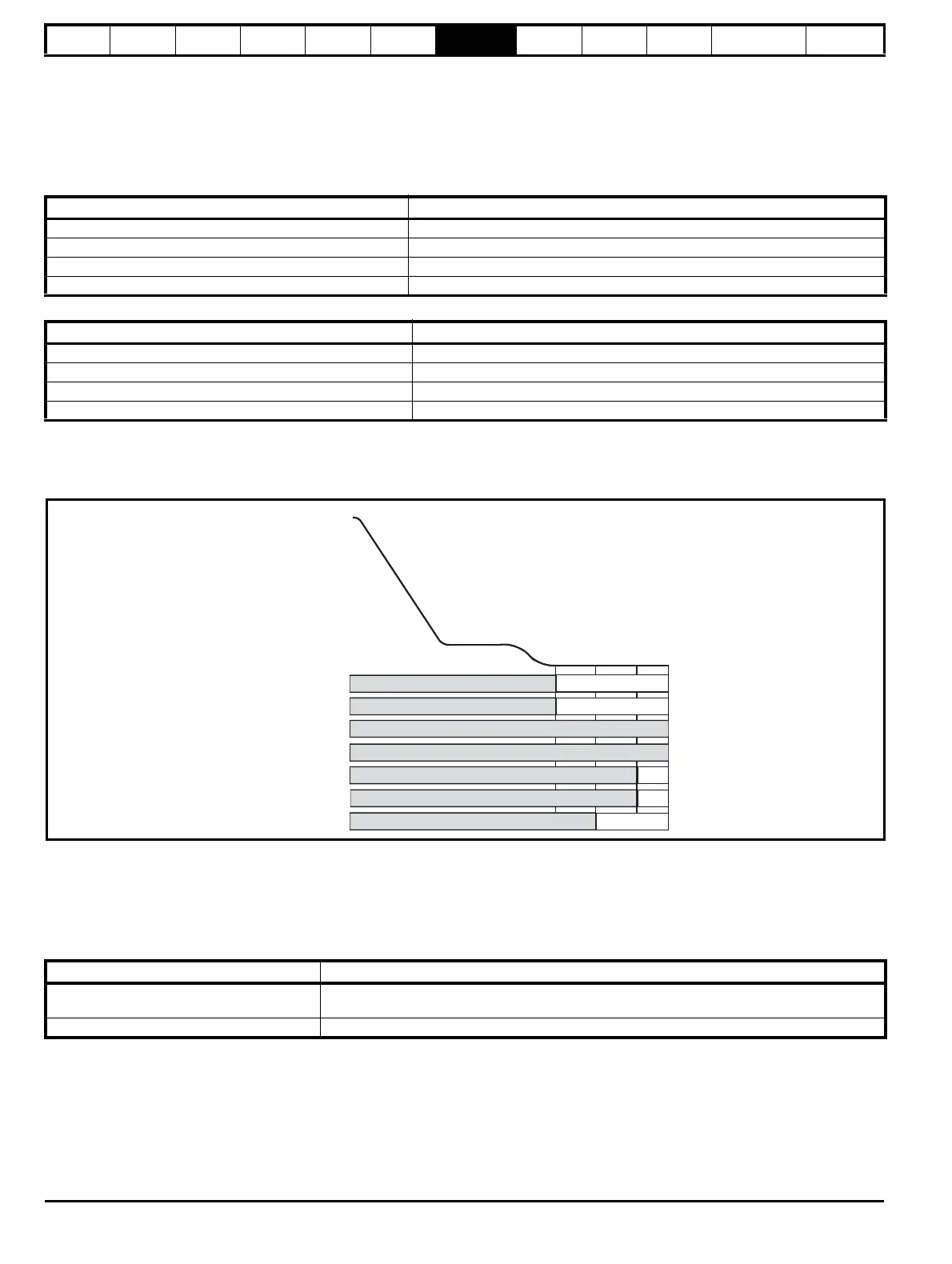

7.9.2 Stop profile brake control

The motor brake control for the Elevator can be controlled either from the E300 Advanced Elevator drive or from the Elevator controller. By default the

drive is set-up to provide a brake control output on control terminal T25. If the Elevator controller manages the motor brake control, the drive can be

configured using T25 Digital I/O 02 Source/Destination (F19) to provide a motor magnetized output. Only once the motor is fully magnetized, does the

drive provide a motor magnetized output which can be used for the brake control in the Elevator controller. Table 7-23 and Table 7-24 describe the

various brake control parameters and settings.

Table 7-23 Brake control digital output parameters

Table 7-24 Brake control parameters

During any drive trip where brake control is being performed, the brake output will become inactive forcing the brake to be closed and preventing

further operation. If the brake control is being carried out by the Elevator controller and a drive trip occurs, the drive ok output will turn Off (0) and the

Elevator controller must apply the motor brake to prevent further operation.

Figure 7-16 Brake control - Closed loop apply

7.9.3 Stop profile, motor contactor control

Following completion of the travel and during the stop sequence the motor brake is applied, after which the symmetrical current limit is ramped down

and the output motor contactors are opened. During the opening of the output motor contactors, the drive’s output should be inactive to avoid

potential damage to both the output motor contactors and the drive as a result of arcing.

Where Motor Contactor Measured Delay Time (B32) is < 50 ms the brake control in Brake Control Apply Delay (D05) should be increased.

Table 7-25 Motor contactor control parameters

Parameter Setting

T25 Digital I/O 02 Source/Destination (F19) Brake Control Output (D03) for brake control output from drive

T25 Digital I/O 02 Source/Destination (F19) Motor Magnetized Indication (D01) for external brake control

T25 Digital I/O 02 State (F04) Digital output state On (1) Off (0)

T25 Digital I/O 2 Invert (F13) Invert digital output on T25

Parameter Detail

Brake Control Output (D03) Brake control output state

Brake Control Apply Delay (D05) Brake apply delay

Brake Apply Low Threshold (D07) Brake control apply low current threshold (Open loop)

Brake Apply Frequency (D07) Brake apply frequency (Open loop)

Parameter Detail

Motor Contactor Measured Delay Time (B32)

Measured time between the end of the travel and the time taken to fully close the output motor

contactors, and remove the Safe Torque Off (STO), Drive enable, value should be > 50 ms

Brake Control Apply Delay (D05) Brake apply delay, increase where Motor Contactor Measured Delay Time (B32) is < 50 ms

Motor contactor

STO, Drive enable

Creep speed

Deflux motor

Motor contactor delay

Speed loop Run Kp

Direction selected

Speed loop Run Ki

Brake control

Brake Control Output ()D03

External motor contactor control

()Creep Stop Jerk G18

()Brake Control Apply Delay D05

Creep Stop Deceleration Rate ()G17

Run Speed Loop P Gain ()I06

Run Speed Loop I Gain ()I07

Loading...

Loading...