LX-300+/1170 Revision C

PRODUCT DESCRIPTION

PECIFICATIONS 14

1.2.2 Paper Feeding

o Feeding method: Friction feed (rear)

Push tractor feed (rear)

Push and Pull tractor feed (rear)

Pull tractor feed (rear, bottom)

o Feeder: Rear push tractor, CSF single-bin (Option),

Pull tractor (Option) and Roll paper holder (Option)

o Paper path: Manual insertion Rear in, top out

CSF Rear in, top out

Push Tractor Rear in, top out

Pull Tractor Rear or bottom in, top out

o Line spacing: 4.23mm (1/6 inch) or programmable in increments of ;

LX-300+: 0.118mm(1/216 inch)

LX-1170: 0.059mm(1/432 inch)

o Feed speed: 4.23mm (1/6 inch feed)

LX-300+ 88msec

LX-1170 63msec

Continuous feed 0.76MPS (m/sec)

[3.0 IPS (inches/sec)]

o Input Data Buffer: 8 Kbyte

o Release lever:

The release lever must be set according to the following table;

o Paper thickness lever:

The paper thickness lever must be set at the proper position as shown below.

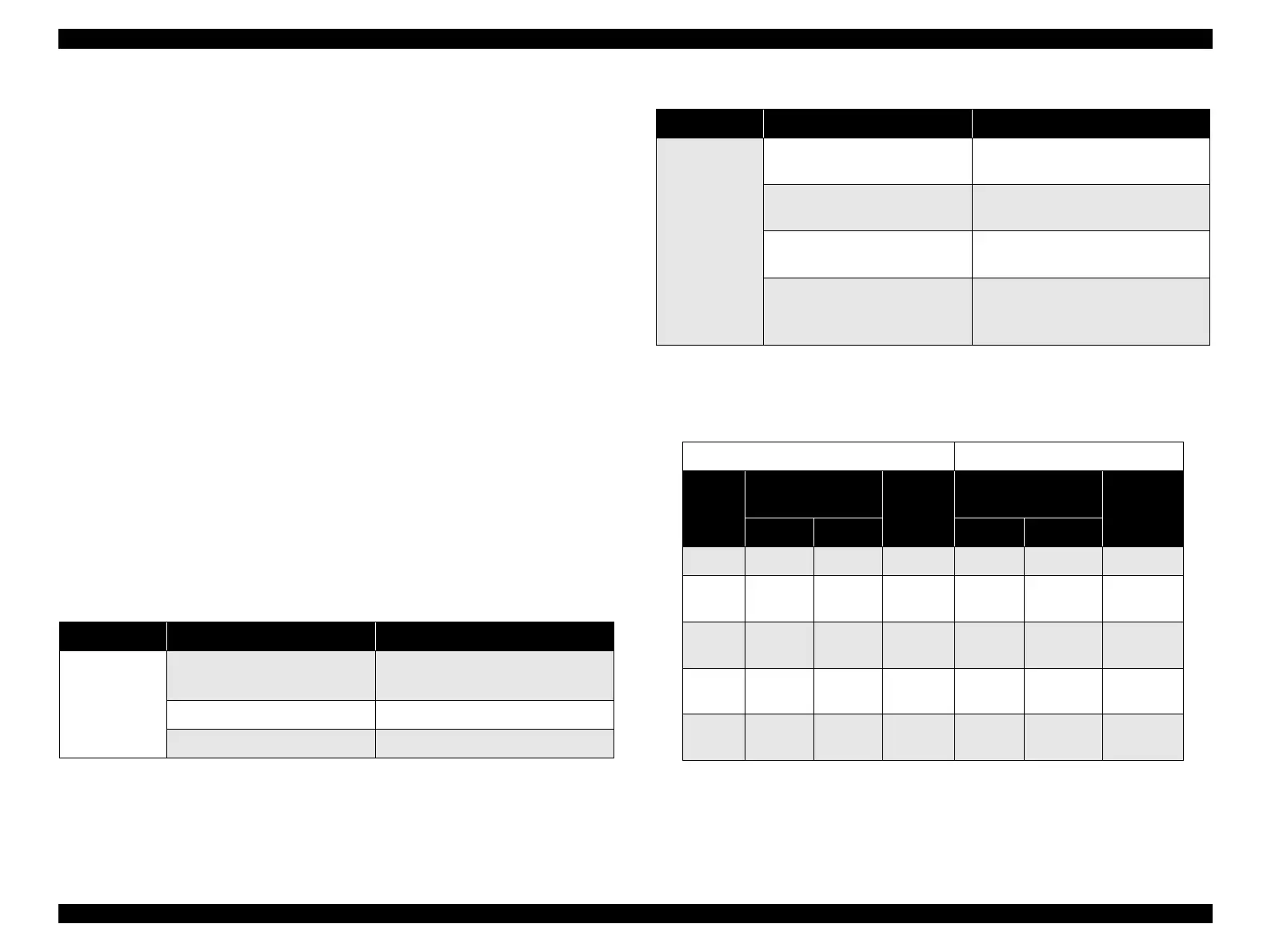

Table 1-4. Release Lever

Lever position Paper path/ Feeder Paper/ Media

Friction

Manual insertion (rear) Cut sheet (Single sheet and Multi part)

Envelop

CSF single-bin Cut sheet (Single sheet)

Roll paper holder feed (rear) Roll paper

Tractor Push tractor feed (rear) Continuous paper (Single sheet and

Multi part)

Push and Pull tractor feed (rear) Continuous paper (Single sheet and

Multi part)

Pull tractor feed (rear) Continuous paper (Single sheet and

Multi part)

Pull tractor feed (bottom) Continuous paper (Single sheet and

Multi part)

Labels

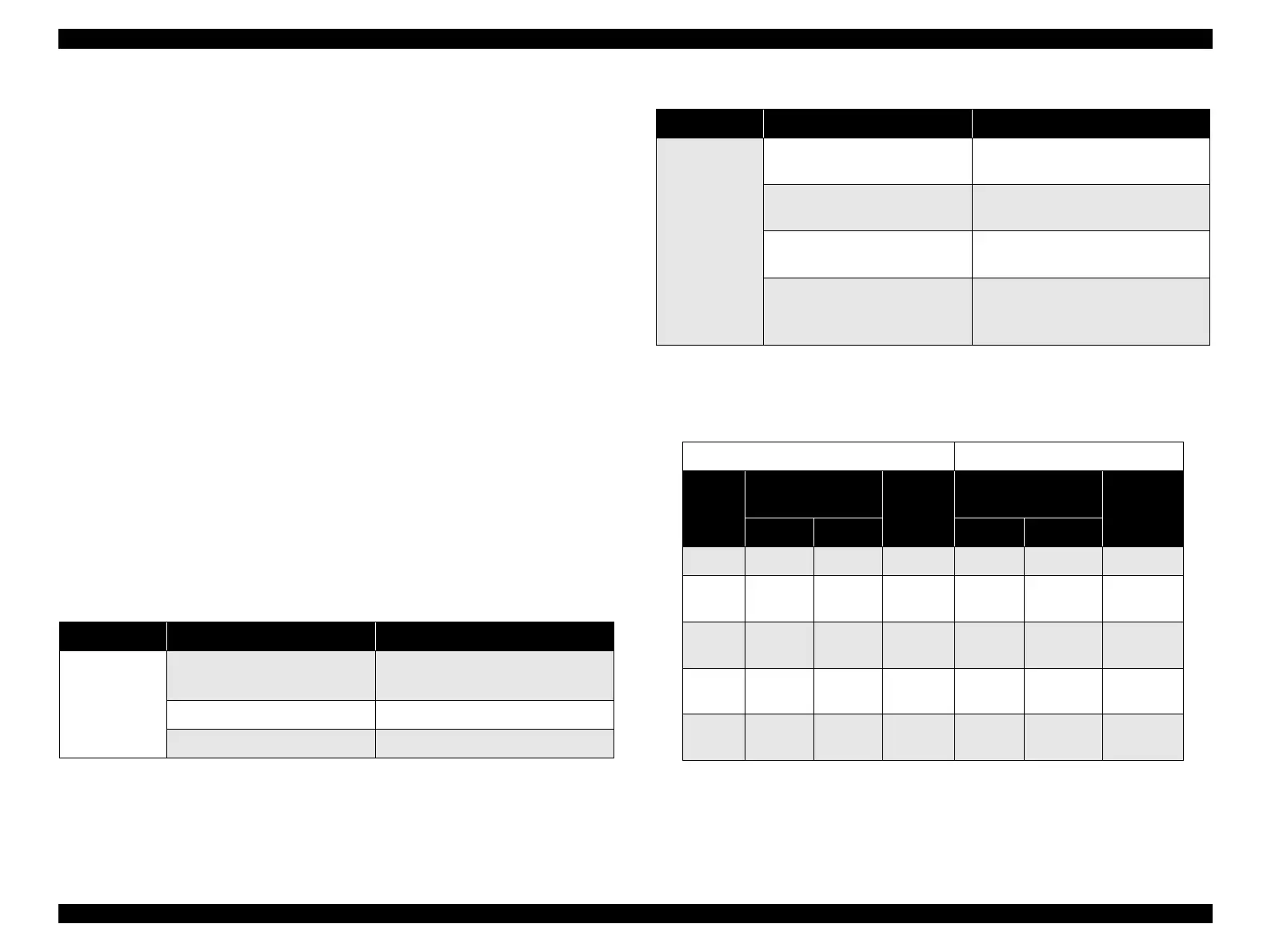

Table 1-5. Paper Thickness Lever

LX-300+ LX-1170

Lever

position

Paper thickness

(inch)

Paper

thickness

(mm)

Paper thickness

(inch)

Paper

thickness

(mm)

Min. Max. Min. Max.

-1 - - - - - -

0 (0.0024) (0.0071)

over 0.06

up to 0.18

(0.0024) (0.0071)

over 0.06

up to 0.18

1 (0.0071) (0.0102)

over 0.18

up to 0.26

- - -

2 (0.0102) (0.0130)

over 0.26

up to 0.33

(0.0071) (0.0102)

over 0.18

up to 0.26

3 (0.0130) (0.0154)

over 0.33

up to 0.39

- - -

Table 1-4. Release Lever

Lever position Paper path/ Feeder Paper/ Media

Loading...

Loading...