LX-300+/1170 Revision C

Adjustment

verview 89

5.1 Overview

This chapter explains the adjustment required after disassembling the printer.

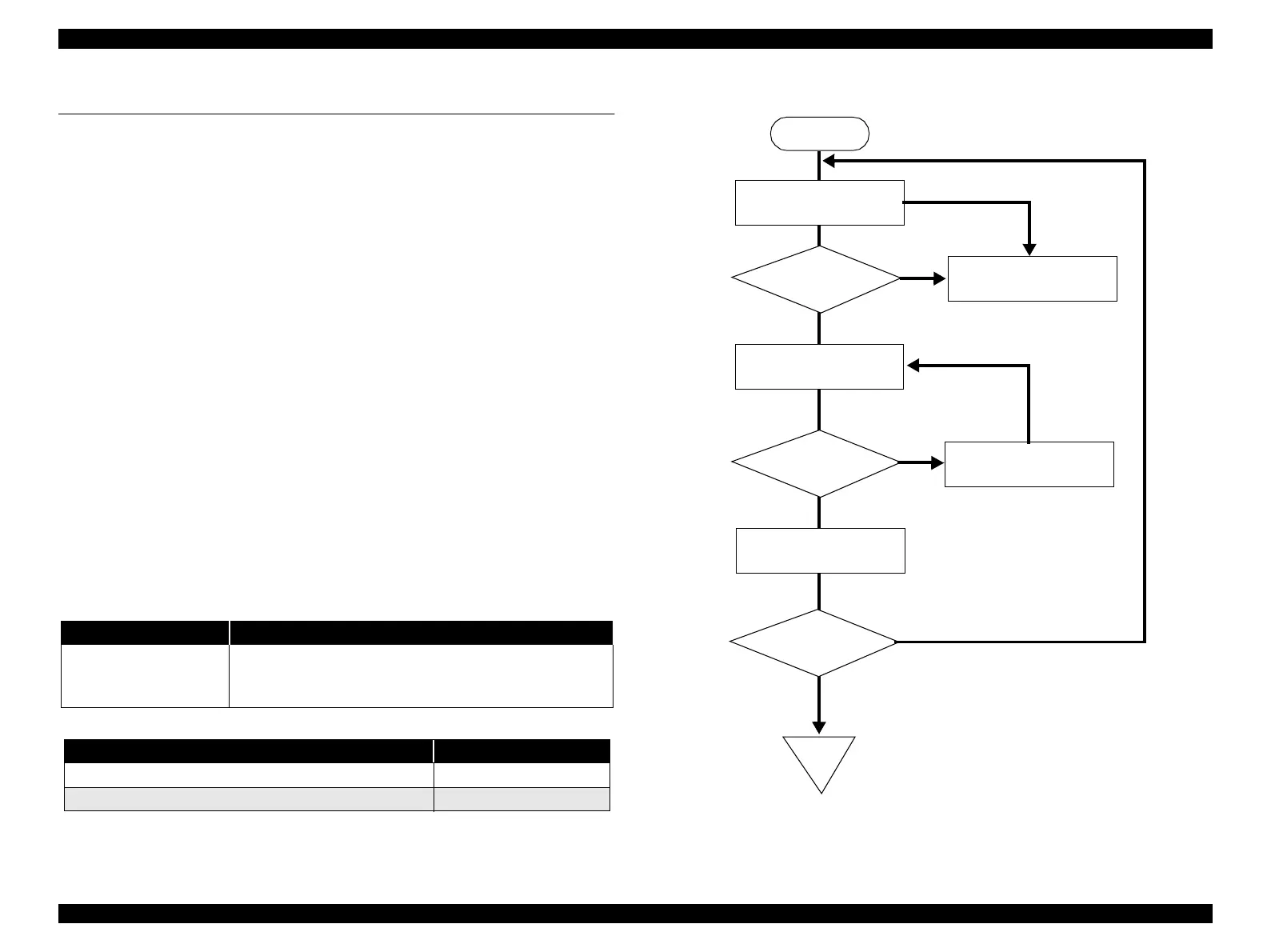

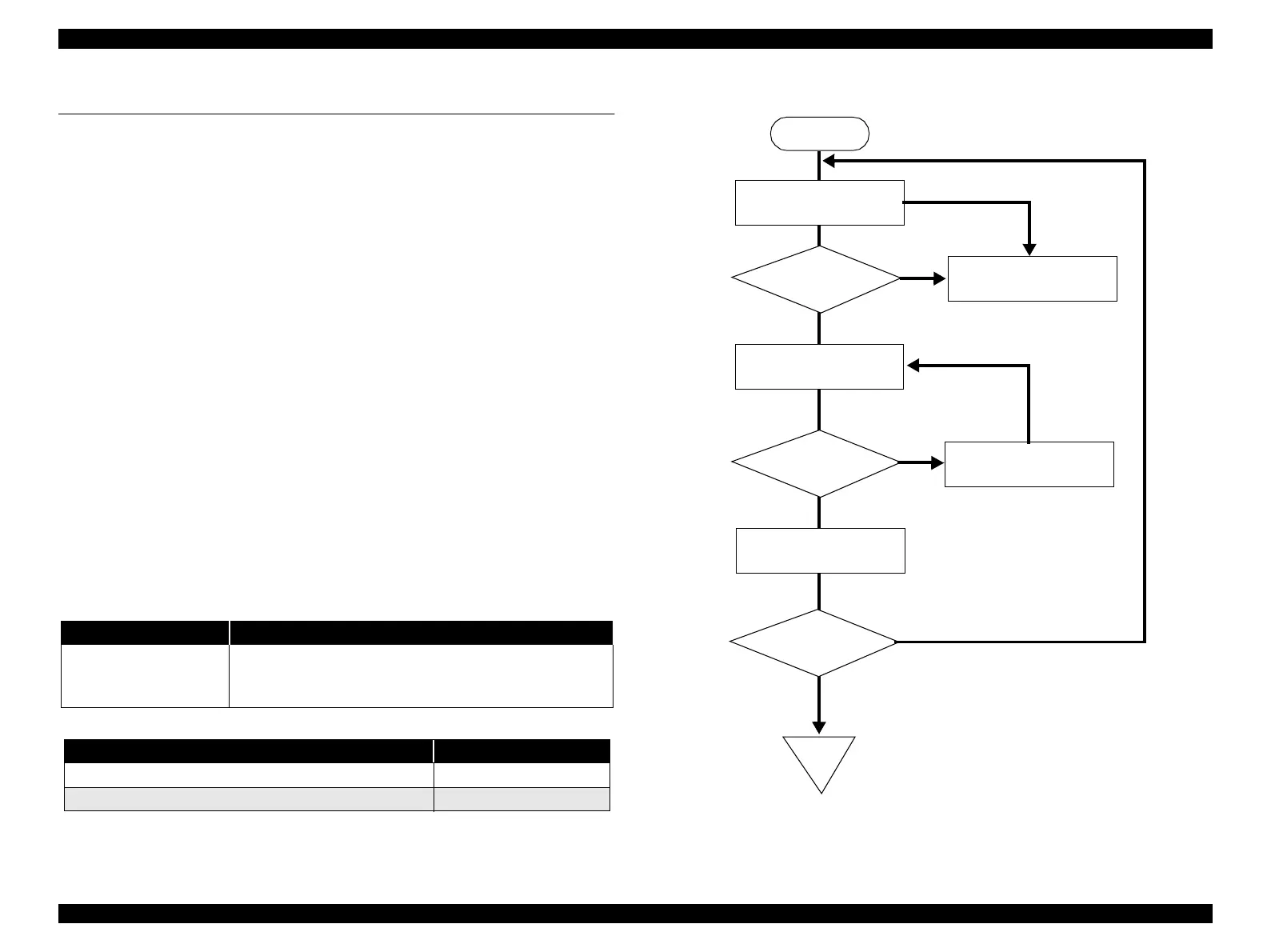

5.1.1 Platen Gap Adjustment

Platen gap adjustment is required at the following cases.

o Printhead is replaced.

o Carriage is replaced.

o CRguideshaftisremoved.

o Parallelism adjust bushing is removed.

o Printing is too thin.

o Ink ribbon often gets jammed.

Follow the steps below before performing the platen gap adjustment.

1. Remove the upper housing. (Refer to Ch4.)

2. Set the PG adjust lever to “0”.

3. Remove the printhead and remove the ribbon mask.

4. Re-install the printhead.

5. Follow the procedure in the flowchart below for the adjustment.

Figure5-1. Platen Gap Adjustment

Table 5-1. Adjustment Method

Platen Gap Setting Judging Method

0415 ± 0.015mm

Thickness gauge 0.40mm falls down by its own weight: OK

Thickness gauge 0.43 mm does NOT fall down by its own

weight: NG

Table 5-2. Parallelism Adjust Bushing

Rotational direction of the parallelism adjust bushing Platen gap

Platen side Widen

Front side Narrowed

START

Move the carriage unit to the

left end.

Move the carriage unit to the

right end.

Is the platen gap

within the range of the

setting?

Move the carriage unit to the

center.

Adjust the platen gap at the

left end.

Adjust the platengap at the

right end.

END

Is the platen gap

within the range of the

setting?

Is the platen gap

within the range of the

setting?

Loading...

Loading...