-- 1 8 --

cdte1de1

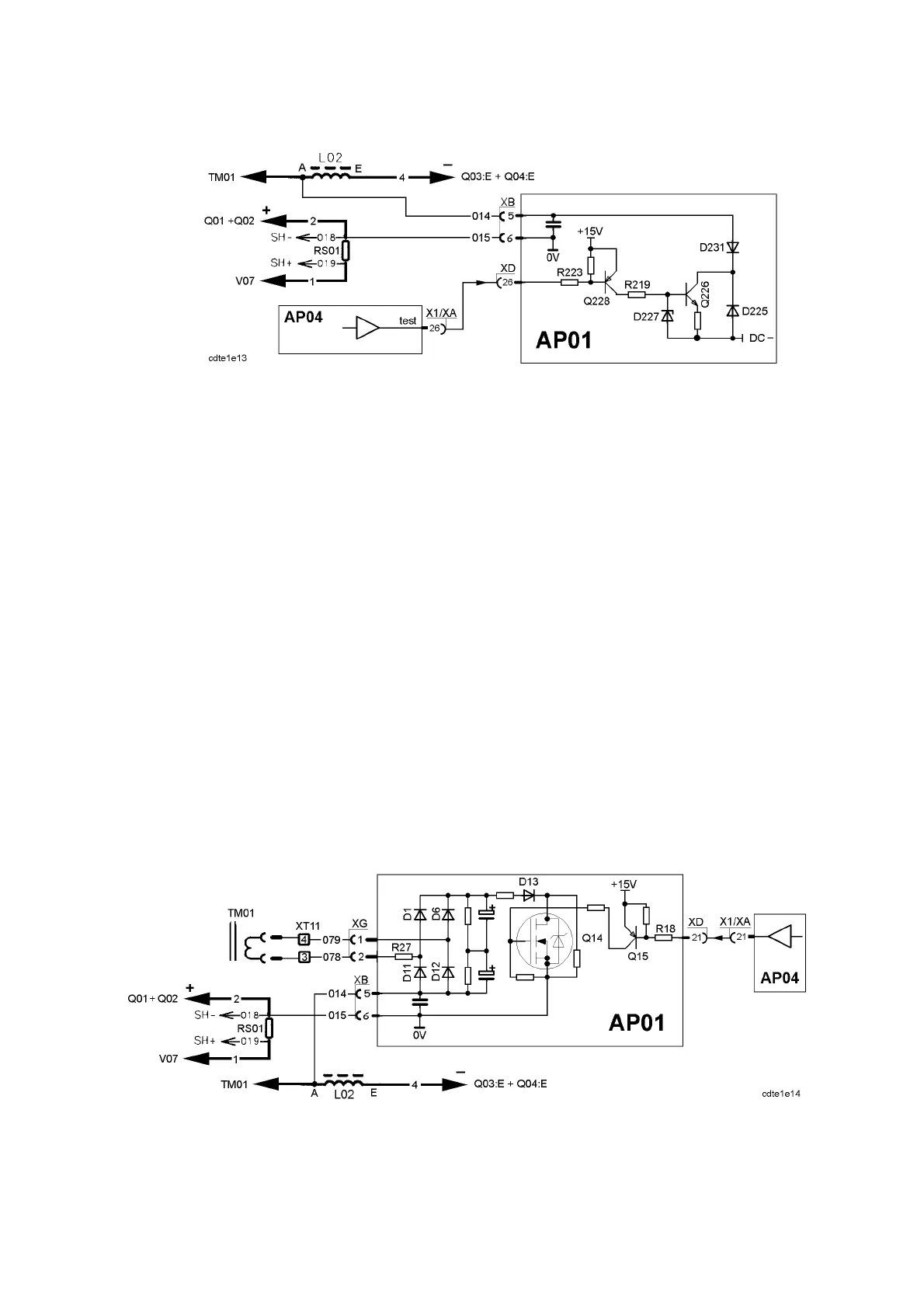

AP01:3a Lift Arc Test voltage

Lift Arc test voltage

In Lift Arc mode a test voltage is used to detect when the electrode is in contact

with the workpiece.

Normally the signal test from AP04 is +15V. When the torch trigger is

depressed it changes to 0V, activating transistors Q228 and Q226. DC--, which is

about --19V, is then connected in parallel with the welding voltage. The emitter

resistor of Q226 limits the current produced by DC-- to about 11mA.

The procedure for the Lift Arc start is as follows:

1. The torch switch is depressed, activating the test voltage and the gas valve.

2. The electrode contacts the workpiece. AP04 senses the change in voltage

via the arc voltage input (see the diagram on page 23). No action is

activated by the machine yet.

3. The electrode is lifted from the workpiece. AP04 senses the voltage change

and activates the modulation, i.e. the machine starts and strikes an arc.

This was a technical description of the Lift Arc start. The welder’s instructions

can be found on page 73.

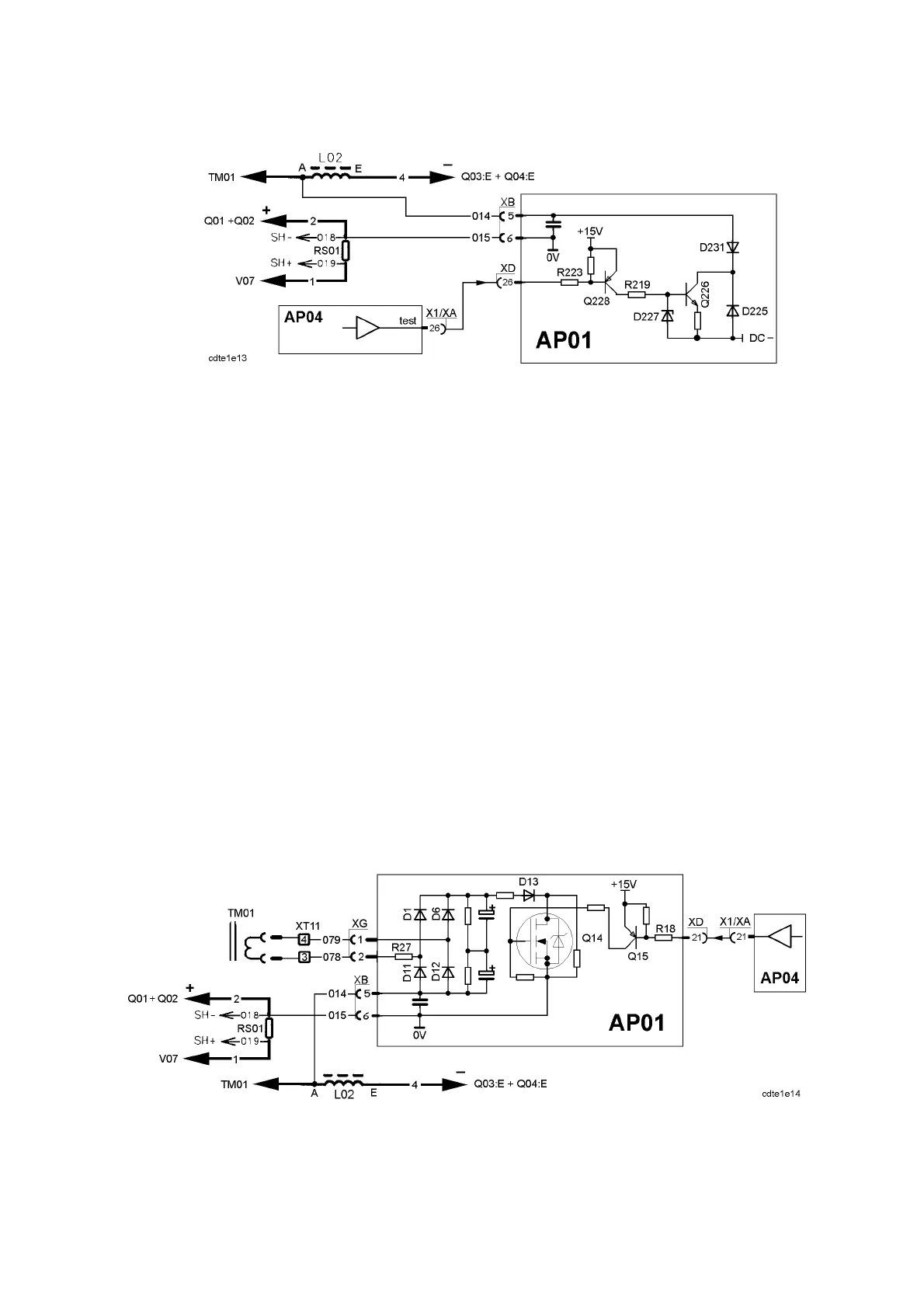

AP01:3b HF Start vo ltage

Auxiliary HF start voltage

To achieve a good HF start, it is neccessary also to increase the voltage at the

electrode during the start. The voltage from an auxiliary winding on the main

transformer is used to produce the increased voltage, which is about 90--100V.

Loading...

Loading...