-- 6 --

cdte1de1

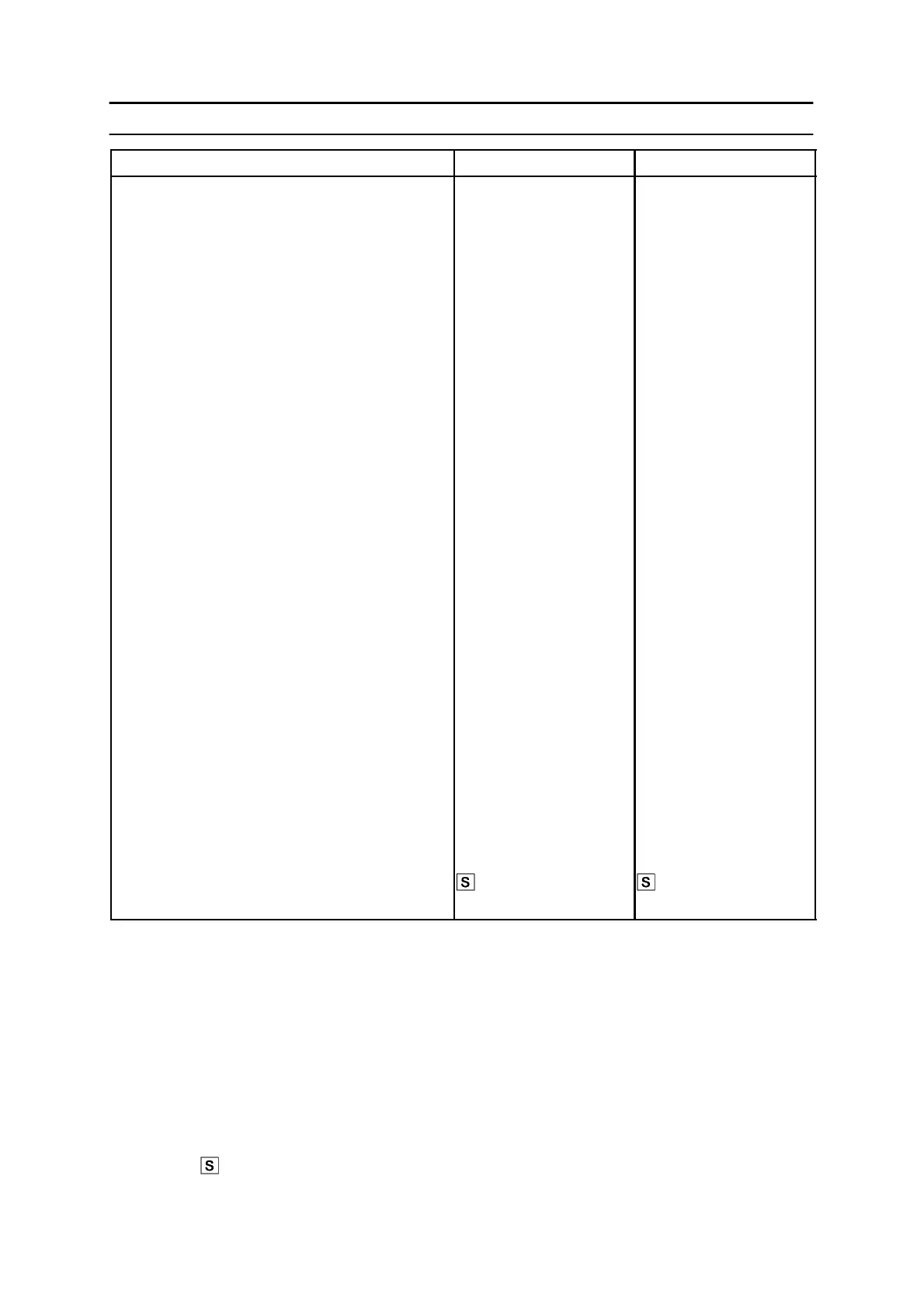

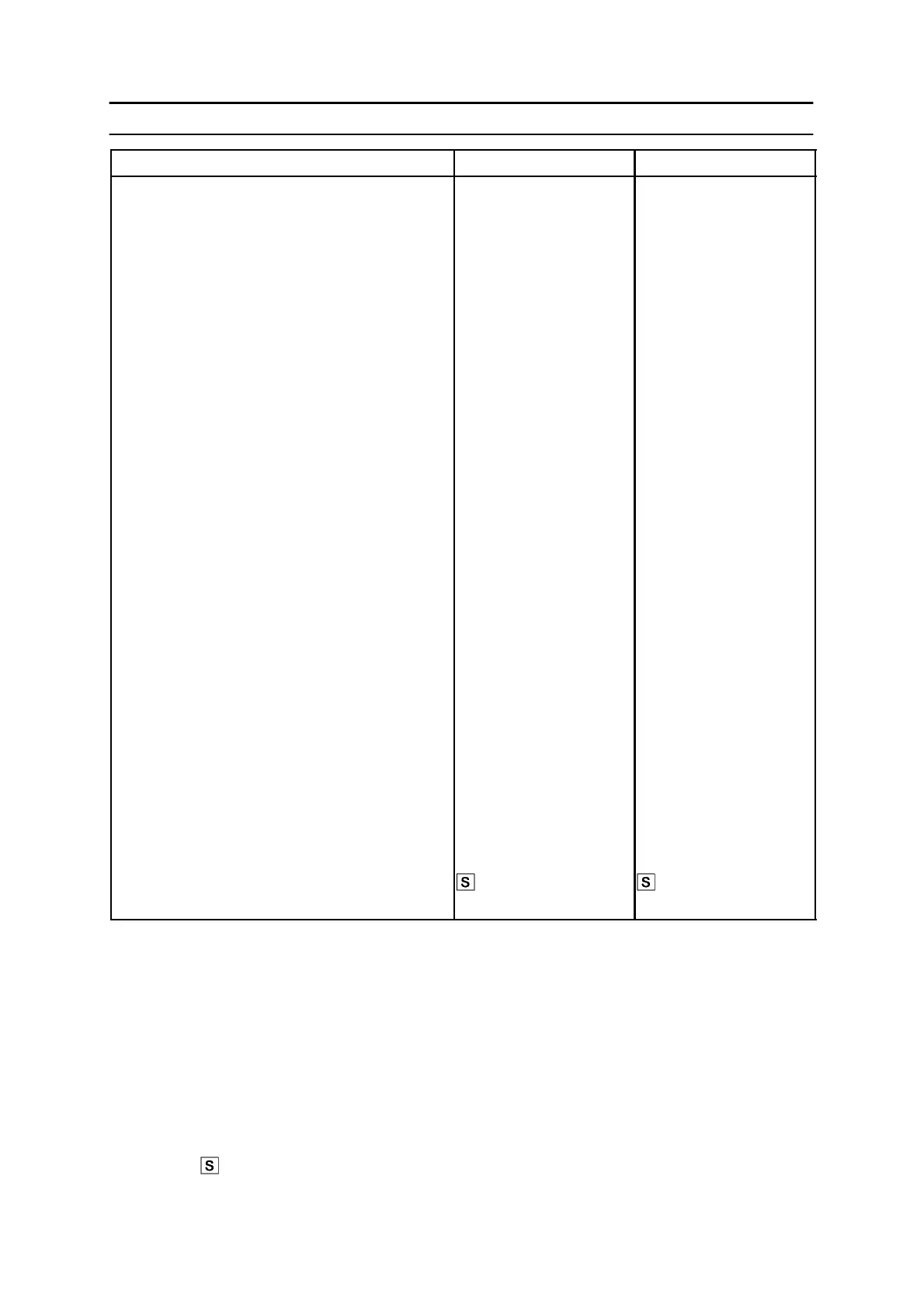

TECHNICAL DATA

DTE 200 DTE 255

Permissible load at

25% duty cycle, MMA

35% duty cycle, MMA

60% duty cycle, MMA

100% dut

c

cle, MM

170 A / 27 V

130 A / 25 V

100

24

250 A / 30 V

200 A / 28 V

165

26

,

35% duty cycle, TIG

50% duty cycle, TIG

60% duty cycle, TIG

100% duty cycle, TIG

200A / 18V

150 A / 16 V

120 A / 15 V

250A / 20V

225 A / 19 V

170 A / 17 V

Setting range TIG 5 -- 200 A DC

5* -- 200 A AC

5 -- 250 A DC

5* -- 200 A AC

Setting range MMA 5 -- 200 A 5 -- 250 A

Slope up 0 -- 10 seconds 0 -- 10 seconds

Slope down 0 -- 10 seconds 0 -- 10 seconds

Gas preflow, adjustable on the circuit board 0 -- 5 seconds 0 -- 5 seconds

Gas postflow 3 -- 30 seconds 3 -- 30 seconds

Open circuit voltage 70 -- 90 V DC 70 -- 90 V DC

No--load power, MMA

No--load power, TIG

115 W

60 W

120 W

60 W

Useful power, P (at max. current MMA) 6.2 kW 10 kW

Apparent power, S (at max. current MMA) 6.4 kVA 10.6 kVA

Power factor at max. current, MMA 0.95 0.93

Efficiency at max. current, MMA 73% 73%

Mains voltage 400V +/-- 10% 3 ~ 400V +/-- 10% 3 ~

Mains frequency 50 -- 60 Hz 50 -- 60 Hz

Welding cable, cross--sectional area 35 mm

2

35 mm

2

Fuse, slow--acting 10 A 16 A

Mains cable, cross--sectional area 4x2.5mm

2

4x2.5mm

2

Dimensions l x w x h 510 x 310 x 555 mm 510 x 310 x 555 mm

Weight 45 kg 45 kg

Application class

Enclosure class IP23 IP 23

These welding power sources fulfil the requirements of IEC 60974--1

*) The minimum current during AC welding depends on the alloy used for the aluminium plates and

their surface cleanliness.

Duty cycle

The duty cycle refers to the time in per cent of a ten--minute period that you can weld at a certain load

without overloading the welding power source.

Enclosure class

The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid

objects or water . Equipment marked IP 23 is designed for indoor and outdoor use.

Application class

The symbol

indicates that the power source is designed for use in areas with increased electrical

hazard.

Loading...

Loading...