-- 4 6 --

cdte1de1

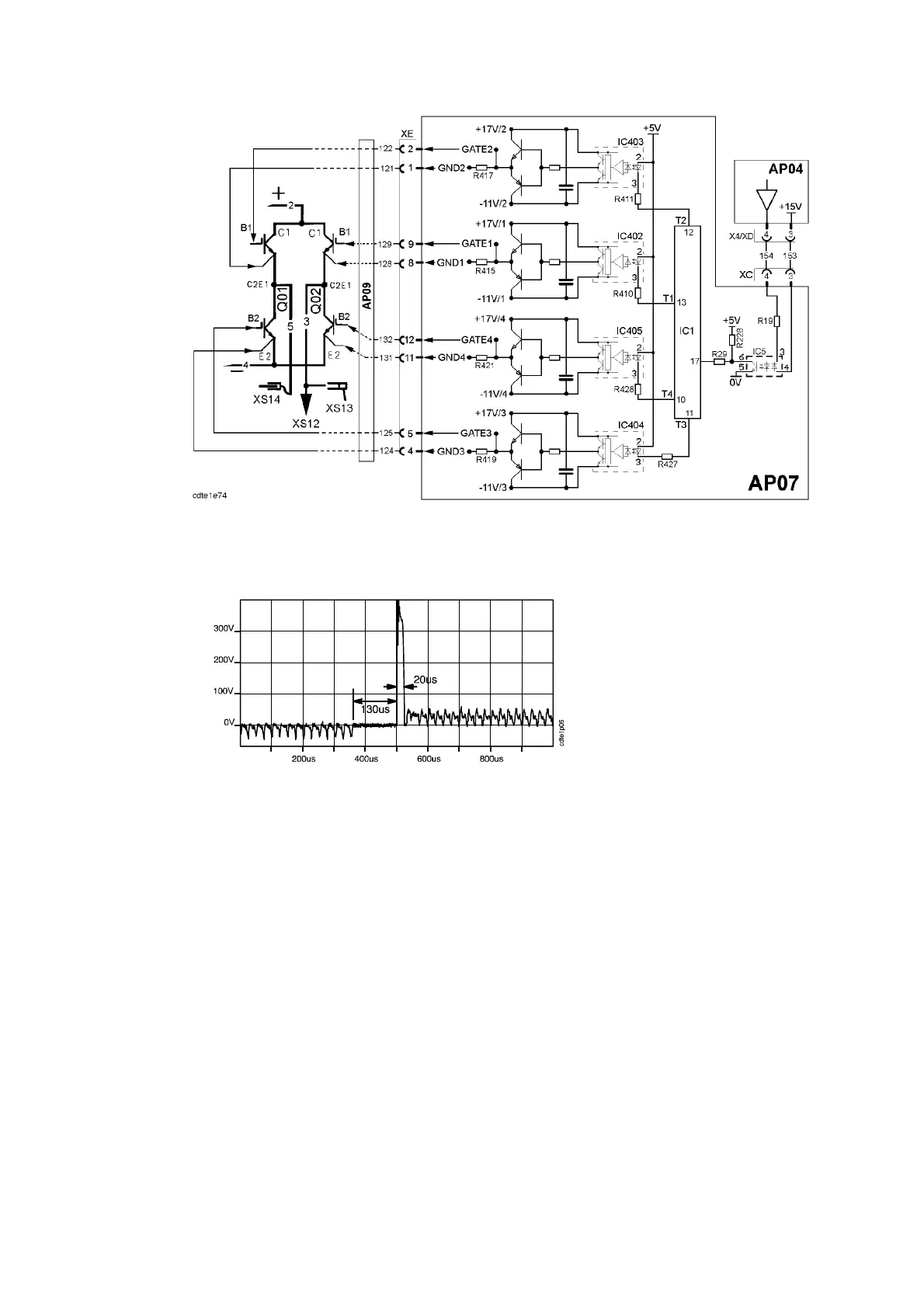

Gate control circuits for the AC IGBTs in the DTE 200

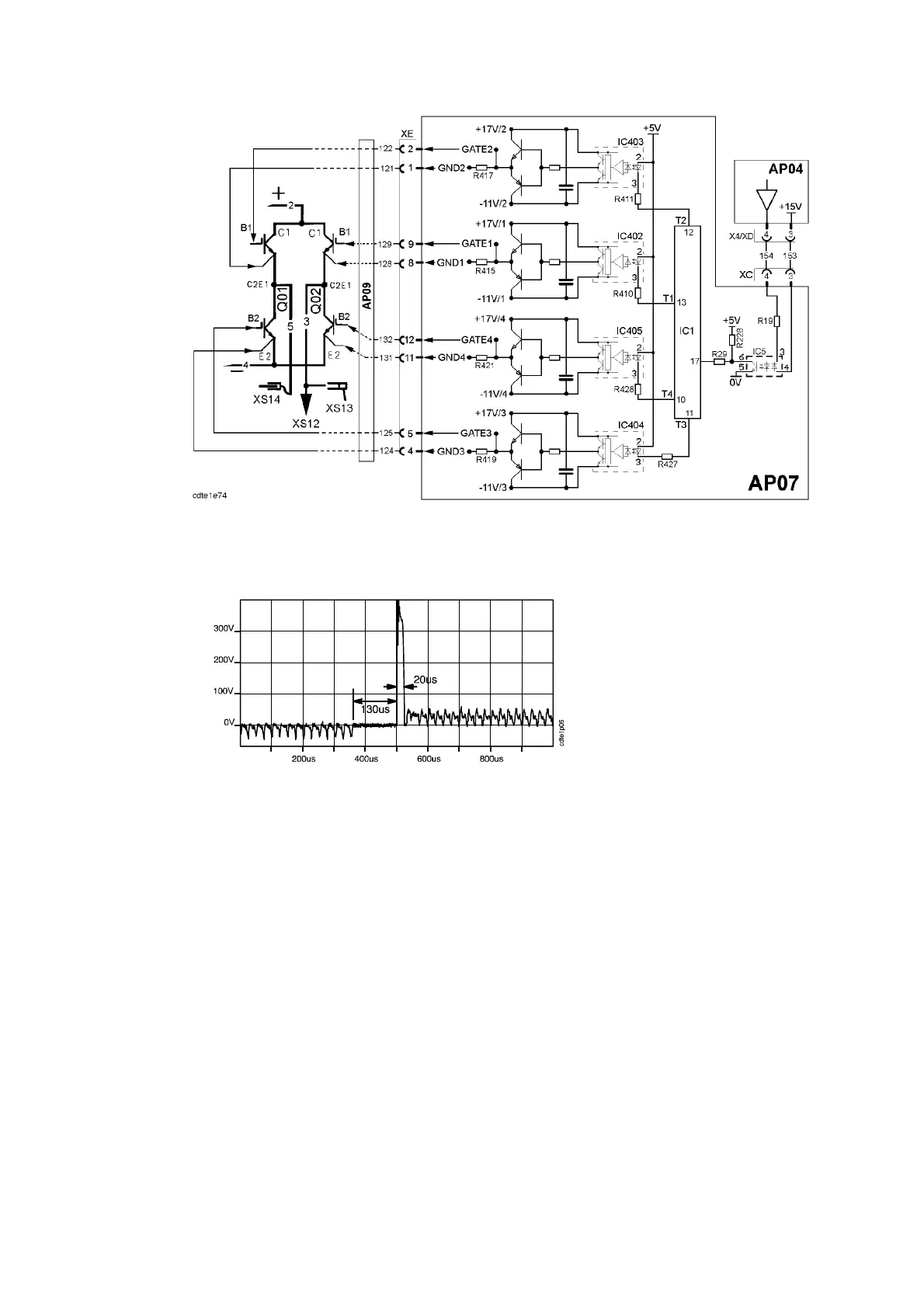

The picture below shows the voltage peak that makes the polarity change so fast

that no additional HF ignition is needed when the polarity is changed.

Voltage between the welding terminals XS14 and XS13 at 200A AC welding

Compare the actual waveform with the above waveform only during AC

welding with a standard torch. The wavef orm above is not valid for a resistive

load.

Looking at the picture above from left to t he right: First the welding voltage is

negative. Then all IGBTs are conducting for 130ms: the voltage is zero. Then

two IGBTs are turned on, producing a positve voltage peak of about 400V for

20ms, after which welding continues at normal welding voltage.

To ensure the correct voltage peak, the welding current must not be too high or

too low during the polarity change. This is controlled by the processor board

AP04.

If the current is lower than 50A, it will be increased to 50A shortly before all the

IGBTs are turned off. After the polarity is changed, the current is the same as it

was originally.

If the current is higher than 100A, it will be decreased to 100A shortly before all

the IGBTs are turned off. After the polarity is changed, the current is the same as

it was originally.

If the current is between 50 and 100A, there is no change in its value before the

polarity is changed.

Loading...

Loading...