175

OILING SYSTEM

OILING SYSTEM TESTS

8

Cylinder Oil Pump Voltage Tests

The EMM controls the pump by providing ground

through pin 4 (blue/red wire) of the J1-A connector

and pin A (blue/red wire) of the oil pump connec-

tor.

Use an appropriate test probe and a digital multi-

meter calibrated to a scale that reads 12 V (DC).

Connect negative meter lead to ground.

Connect positive meter lead to pin A (blue/red

wire) of oil injection pump electrical connector.

Turn the key switch to the ON position. Observe

voltage at pin A.

• Voltage at pin A should be approximately 12 V.

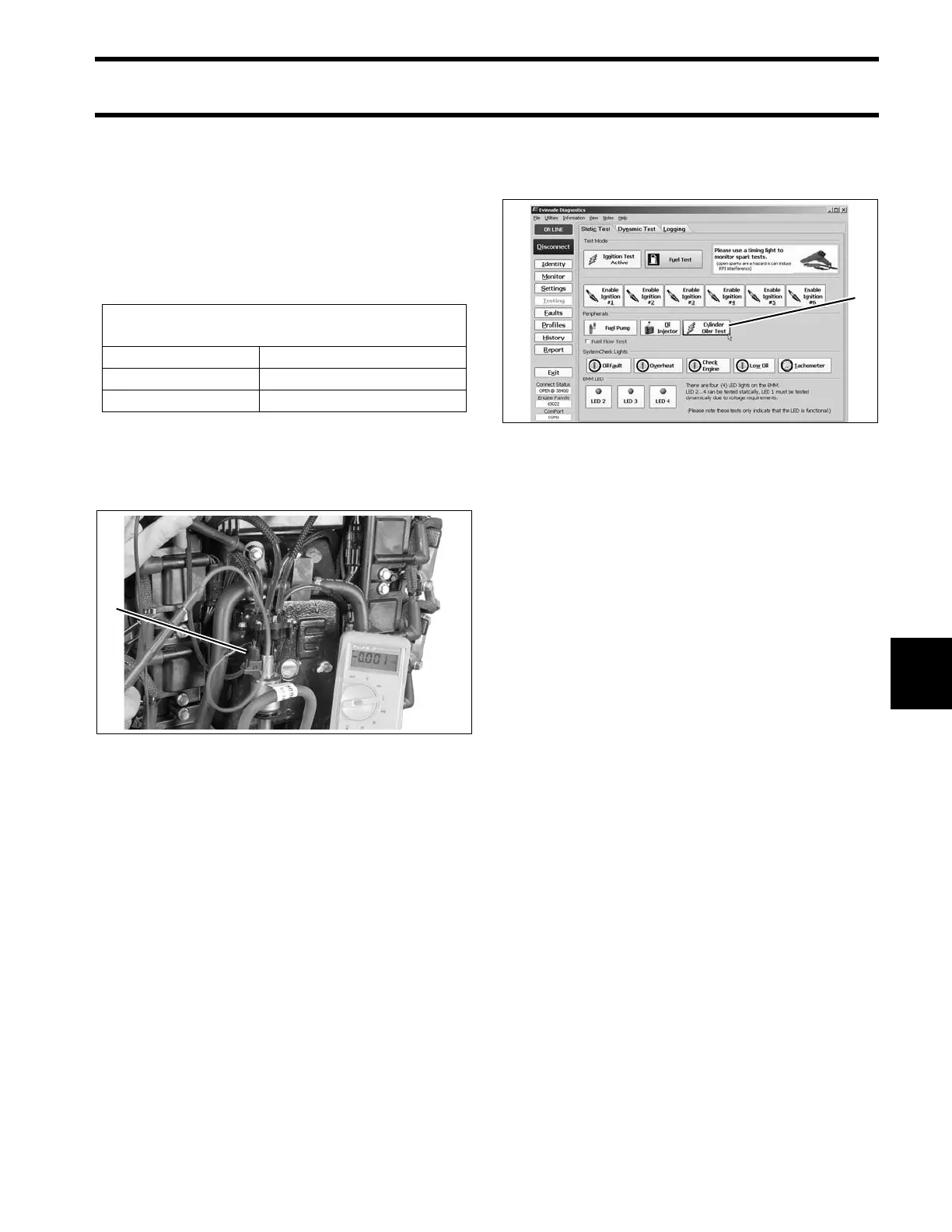

Use the Cylinder Oiler Test function of Evinrude

Diagnostic software Static Test screen to activate

the cylinder oil pump.

• Voltage at pin A should vary (drop), as the oil

pump cycles.

Check the control signal while the Oil Injector test

is running. Set the digital multimeter to the Hertz

(Hz) scale.

• Meter should read approximately 2 Hz.

Results:

• If voltage and control signal readings (Hz) at

pin A are within range, the EMM and wiring are

not at fault.

• If voltage at pin A is not within range, check volt-

age at pin B (red/yellow wire) of the oil pump

electrical connector.

Connect positive meter lead to pin B (red/yellow

wire) of oil injection pump electrical connector.

Observe voltage at pin B.

• The voltage at pin B should be approximately

12 V.

Start the engine. Observe voltage at pin B.

• The voltage at pin B should be approximately

12 V.

• If voltage at pin B is within range, refer to Cylin-

der Oil Pump Resistance Test on p. 176.

• No voltage reading at pin B, check continuity

between pin B of oil pump electrical connector

and pin 24 of EMM J1-B connector.

Acceptable Cylinder Oil Pump

Test Readings

Key switch ON approximately 12 VDC

Control signal approximately 2 Hz

Engine running approximately 12 VDC

1. Oil injection pump connector 008445

Static Test Screen

1. Cylinder oiler test

008468

Loading...

Loading...