170

OILING SYSTEM

OIL SUPPLY PRIMING

OIL SUPPLY PRIMING

Oil Hose Priming

Insert the oil supply hose from the oil tank into a

suitable container. Squeeze the oil primer bulb

until oil flows from the oil tank into the container.

Once oil supply hose from the oil tank is filled with

oil, connect the hose to the oil supply fitting on

outboard and secure with Oetiker clamp.

Oil Pump Priming

Squeeze the oil primer bulb until oil flows from the

oil supply hose, through the oil filter, and into the

crankcase oil pump (front oil pump).

IMPORTANT: Inspect oil filter to make sure it is

filled with oil. All air must be eliminated from the oil

filter during priming procedure.

Continue to squeeze the oil primer bulb until oil

flows through the front oil pump, into the oil distri-

bution hoses, and to the crankcase fittings.

Use Evinrude Diagnostics software to make sure

the EMM is programmed for the type of oil being

used.

250 – 300 HP (3.4 L) MODELS

Start the outboard. Use the oil priming functions in

the software to make sure the system is com-

pletely primed.

IMPORTANT: The outboard should be running

during the priming procedure to avoid pumping

too much oil into the crankcase, which could

cause a hard-starting condition.

Prime the rear oil pump FIRST (cylinder oil pump).

Use the Prime Cylinder Oiler button of the

Dynamic Test screen to prime the rear oil pump.

With the Prime Cylinder Oiler function activated,

continue to squeeze the oil primer bulb until oil

flows through the oil distribution hoses of the rear

oil pump.

The software priming function must

be used along with the primer bulb for two rea-

sons:

• The primer bulb alone will not move oil

through the rear pump assembly unless the

pump is running.

WARNING

Always use caution while working around

machinery with moving parts. The follow-

ing set-up procedures require running

tests that are performed with the out-

board’s motor cover removed.

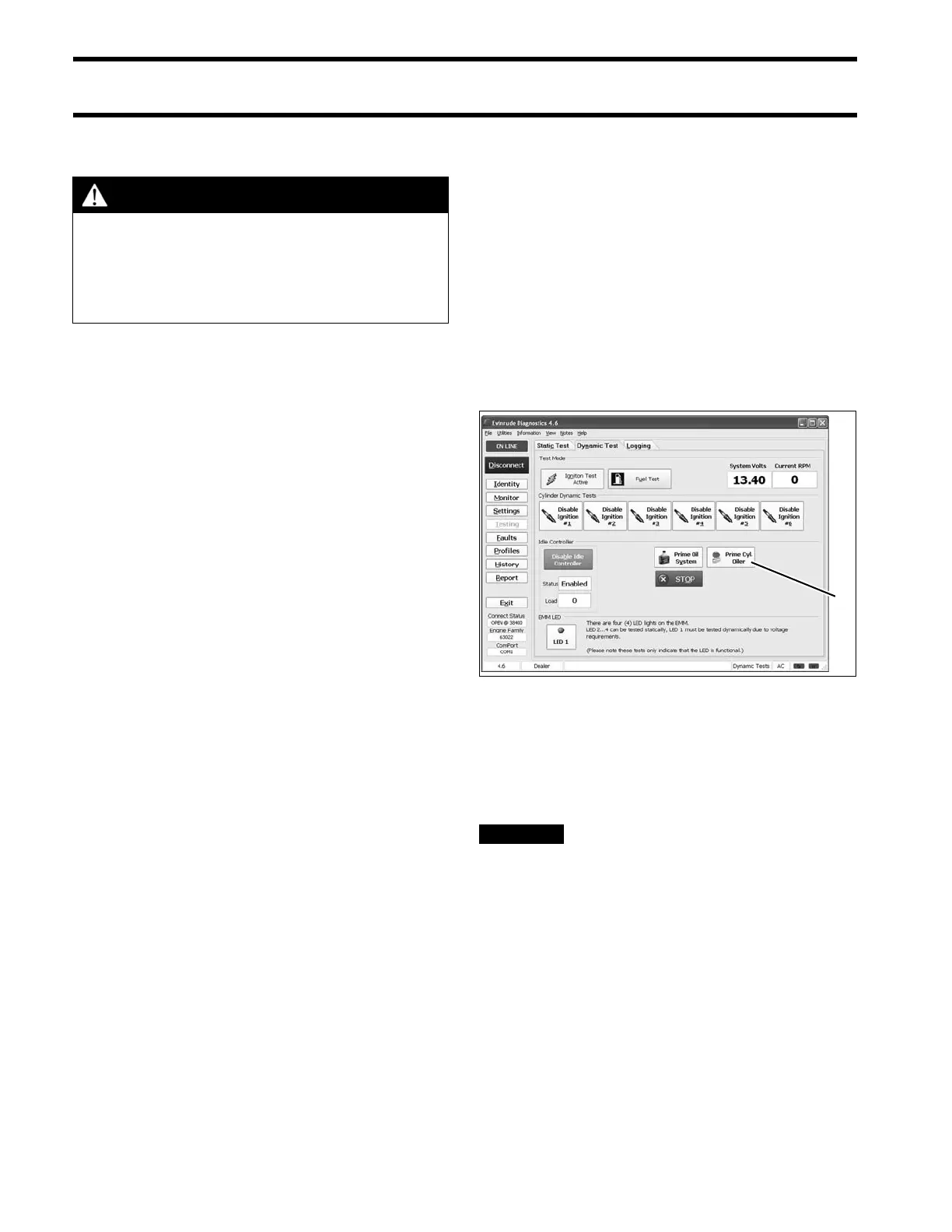

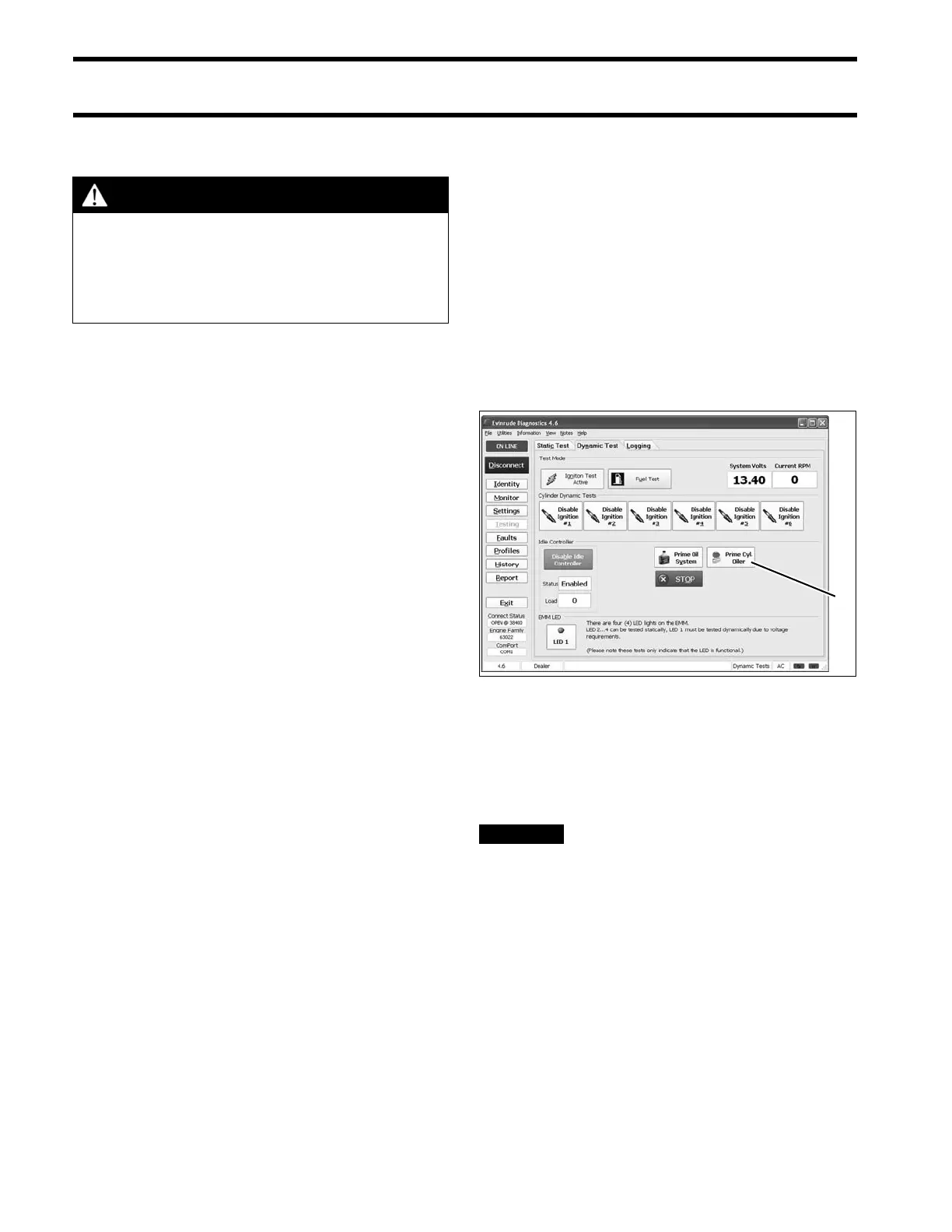

Dynamic Tests Screen

1. Prime Cylinder Oiler button

008390

Loading...

Loading...