239

POWERHEAD

POWERHEAD INSTALLATION

11

POWERHEAD

INSTALLATION

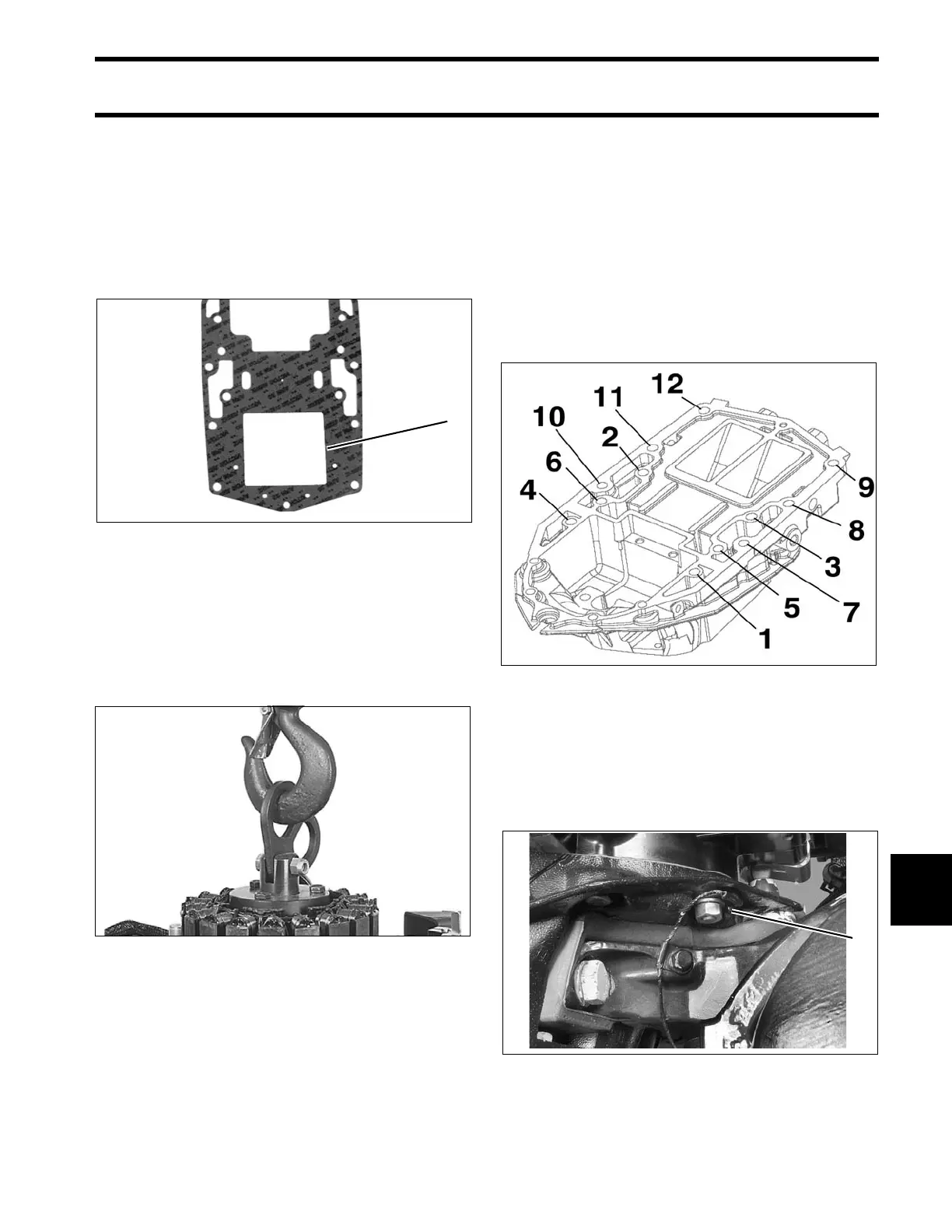

Apply Permatex No. 2 to both sides of a new base

gasket around the exhaust port only. Install gasket

on adapter. To ensure proper sealing, mating sur-

faces must be clean and dry.

Coat the driveshaft splines with Moly Lube. Do not

apply lubricant to end of driveshaft.

Use Lifting Fixture, P/N 396748, and hoist to

slowly lower powerhead onto exhaust housing. If

necessary, rotate flywheel in a clockwise direction

to align crankshaft and driveshaft splines.

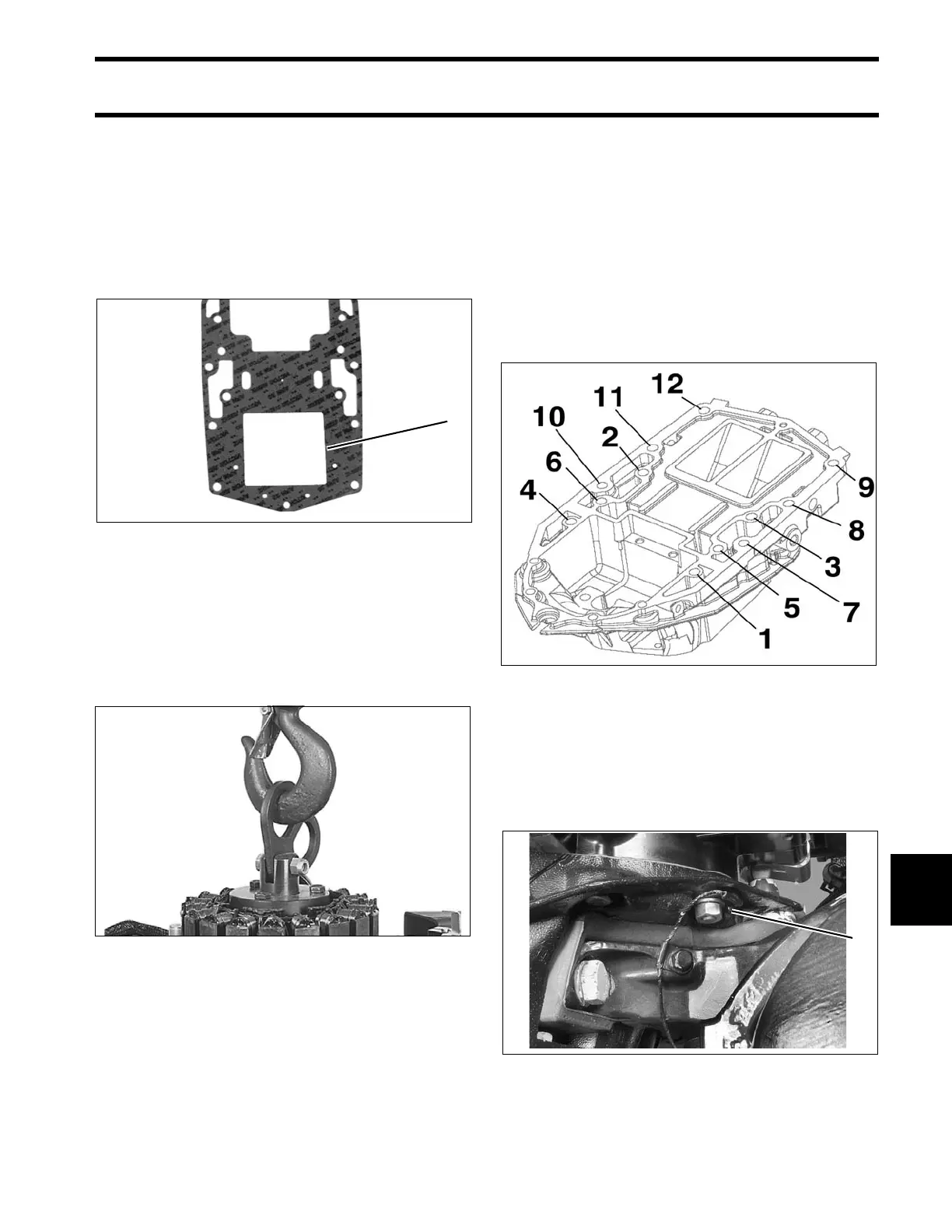

Apply Gasket Sealing Compound to the threads of

all powerhead screws.

Loosely install all fasteners before tightening.

Tighten the 3/8 in. diameter powerhead screws to

a torque of 20 to 22 ft. lbs. (27 to 30 N·m) in the

sequence shown.

Tighten the 5/16 in. diameter powerhead screws

to a torque of 144 to 168 in. lbs. (16.5 to 19 N·m)

in the sequence shown.

IMPORTANT: Retighten powerhead mounting

screws after outboard has been run at full operat-

ing temperature and allowed to cool.

Install two front and one rear powerhead nuts.

Tighten nuts 144 to 168 in. lbs. (16.5 to 19 N·m).

1. Inner exhaust area 000661

48758

004261

1. Front powerhead nut (2) 004262

Loading...

Loading...