177

OILING SYSTEM

OILING SYSTEM TESTS

8

on the hose for at least five minutes. Repair or

replace any leaking components. Reinstall the oil

hose.

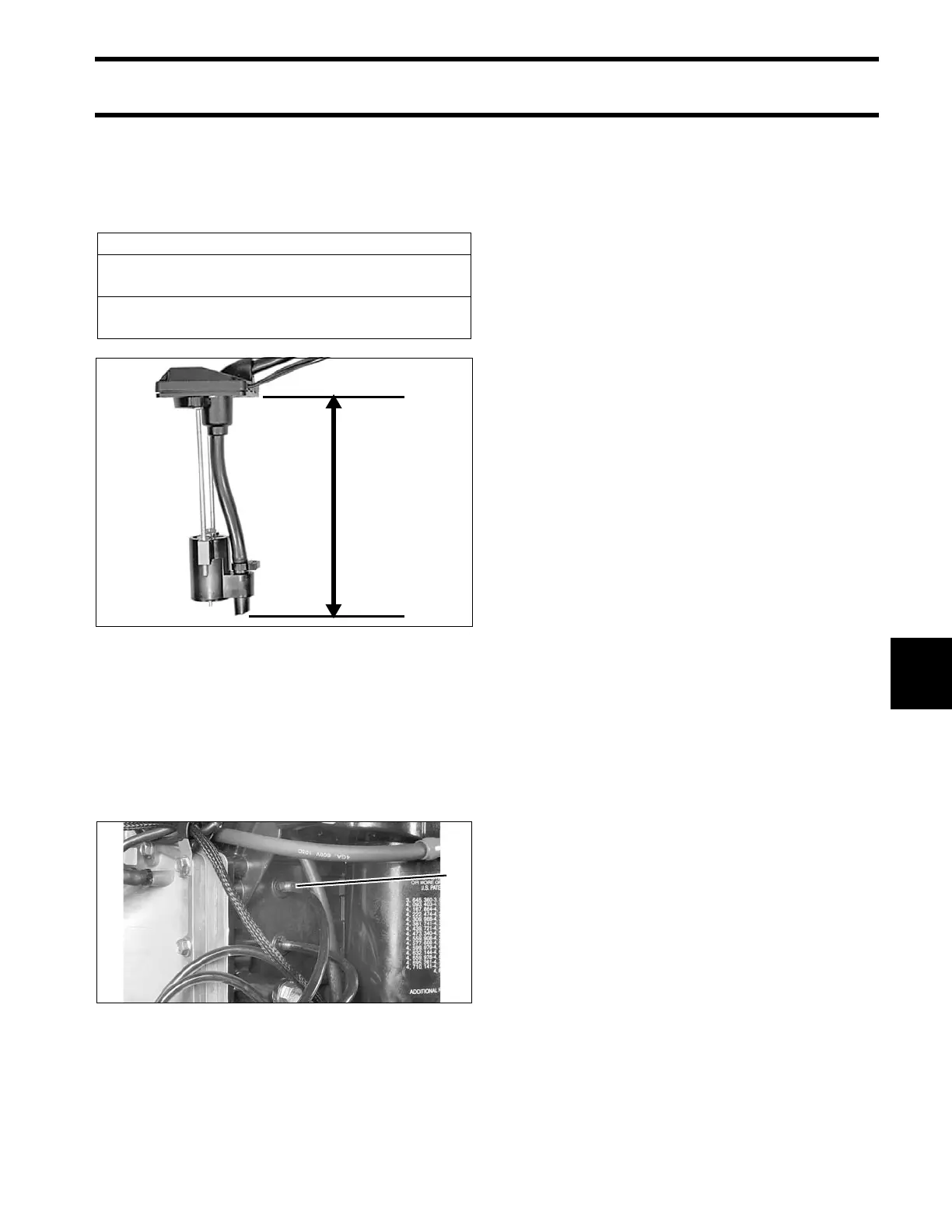

Check height of pickup assembly.

Place a new seal on oil tank and reinstall pickup

with filter into oil tank. Install and tighten screws.

Oil Injection Pump Function Test

Remove oil distribution hose from fitting at crank-

case. Squeeze oil supply primer bulb to provide oil

to injection pump.

Running Test

Start the outboard and observe oil flow. Confirm

that a small amount of oil is discharged while

injection pump is activated.

Static Test

Use the Evinrude Diagnostics software oil injector

test to activate injector. Confirm that a small

amount of oil is discharged while injection pump is

activated.

Results:

• Oil flows from distribution hose, compare to oil

flow at other distribution hoses.

• If one or more hoses fail to discharge oil, check

for a kinked or restricted hose before replacing

the oil injection pump assembly.

Oil Injection Fittings Flow Test

Make sure the oil injection fittings of the cylinder

and crankcase assembly allow fluid to move.

Remove oil distribution hose from crankcase fit-

ting. Temporarily install a length of oil hose.on the

fitting.

Use a Syringe, P/N 346936, filled with isopropyl

alcohol to force fluid through hose and fitting.

LOW OIL Sending Unit Test

Remove oil from the oil tank

Turn the key switch ON. The dash mounted

Engine Monitor system should show a LOW OIL

warning.

Once the warning has been confirmed, refill the oil

tank. The LOW OIL warning should stop when the

oil level exceeds one-quarter of oil tank’s capacity.

Pickup Assembly Height

1.8 gallon tank

6.84 to 6.96 in.

(174 to 177 mm)

3.0 gallon tank

8.74 to 8.86 in.

(222 to 225 mm)

Height of Oil Pickup Assembly COB5657A

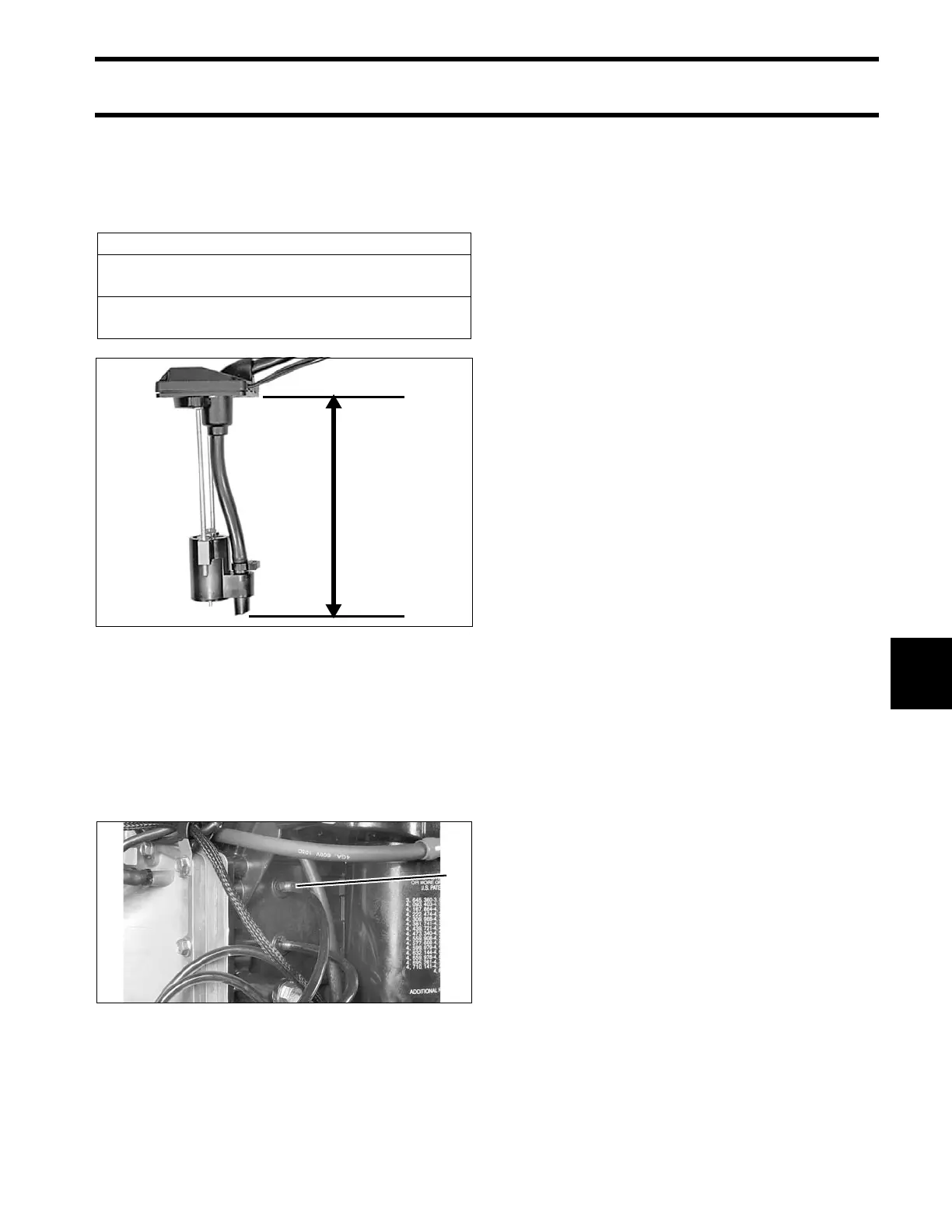

1. Crankcase fitting 004224

Loading...

Loading...