8 Installation of the Transducers FLUXUS F808, F809

UMFLUXUS_F808_8091V1-2-1EN, 2019-08-23 89

Installation of the rail with ratchet clasp

• Cut the tension strap to length (pipe circumference + at least 120 mm).

• Insert approx. 100 mm of the tension strap the into part 1 and 2 of the ratchet clasp (see Fig. 8.36 a).

• Bend the tension strap.

• Insert the tension strap into part 1 of the ratchet clasp (see Fig. 8.36 b).

• Tighten the tension strap.

• Insert the long end of the tension strap into the tension strap clamp and the metal spring (see Fig. 8.37). It is not neces-

sary to mount the metal spring:

– on steel pipes or

– on pipes with an outer pipe diameter < 80 mm or

– on pipes that are not subjected to significant temperature fluctuations.

• Place the tension strap around the pipe (see Fig. 8.38).

• Position the metal spring (if mounted), the ratchet clasp and the tension strap clamp:

– on a horizontal pipe, mount the tension strap clamp on the side of the pipe, if possible

– mount the metal spring (if necessary) on the opposite side of the tension strap clamp

• Insert the long end of the tension strap into part 3 of the ratchet clasp (see Fig. 8.39).

• Tighten the tension strap.

• Cut off the protruding tension strap (see Fig. 8.39).

• Tighten the screw of the ratchet clasp.

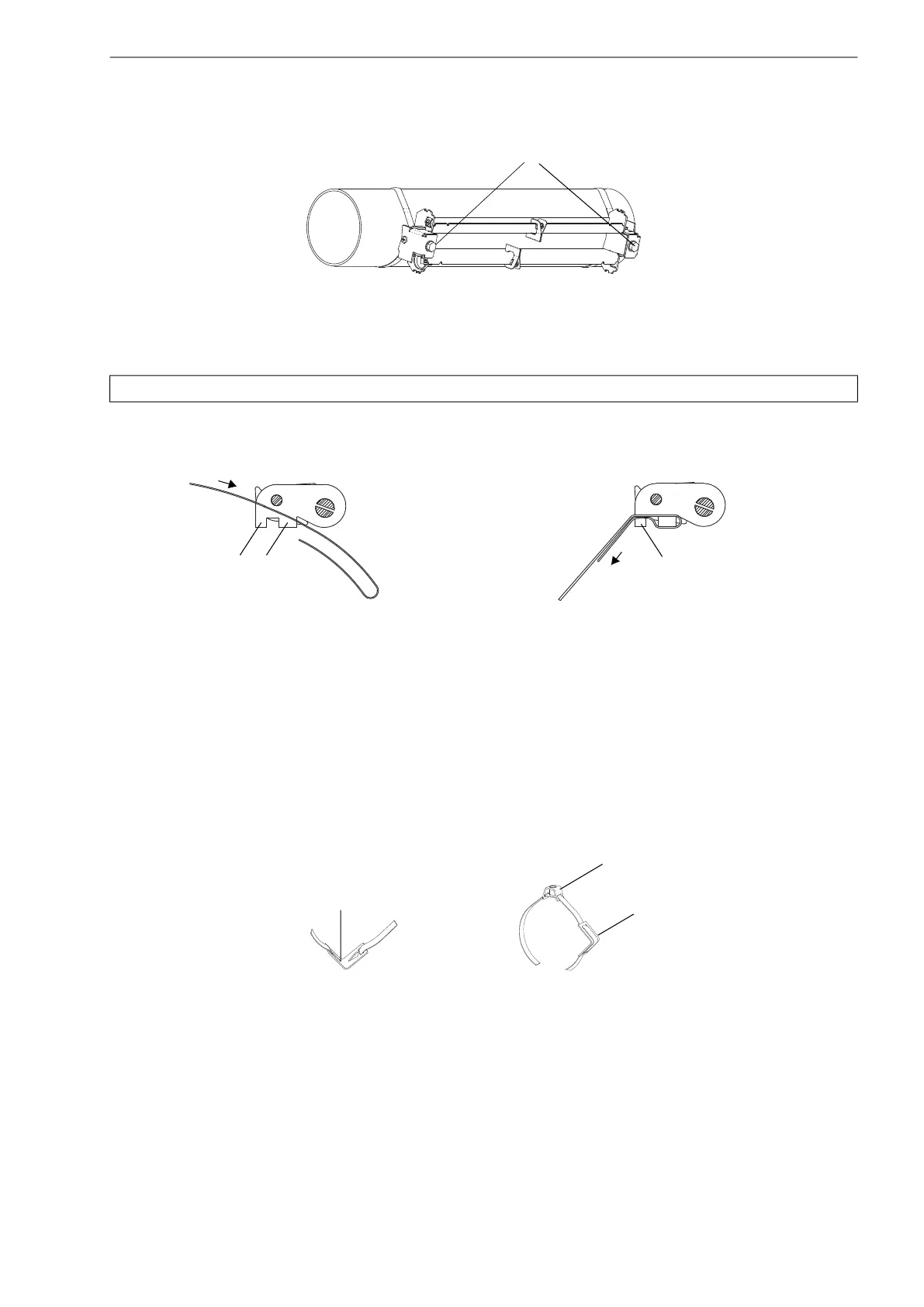

Fig. 8.35: Rail on the pipe

Note! The edge of the tension strap is very sharp, leading to risk of injury. Debur sharp edges.

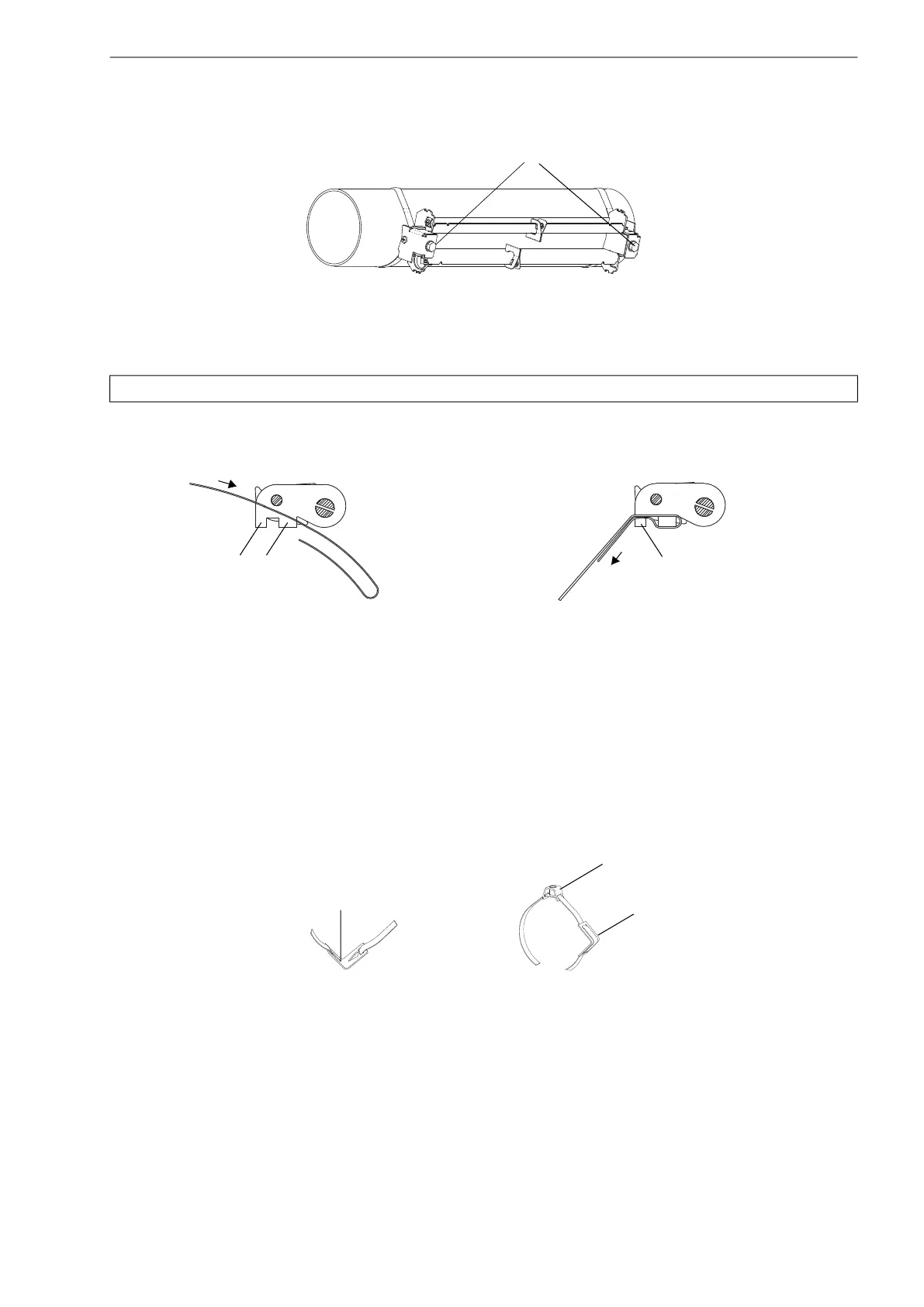

a b

Fig. 8.36: Ratchet clasp with tension strap

Fig. 8.37: Tension strap with metal spring and tension strap clamp

screws

1 2

1

metal spring

tension strap clamp

metal spring

Loading...

Loading...