48

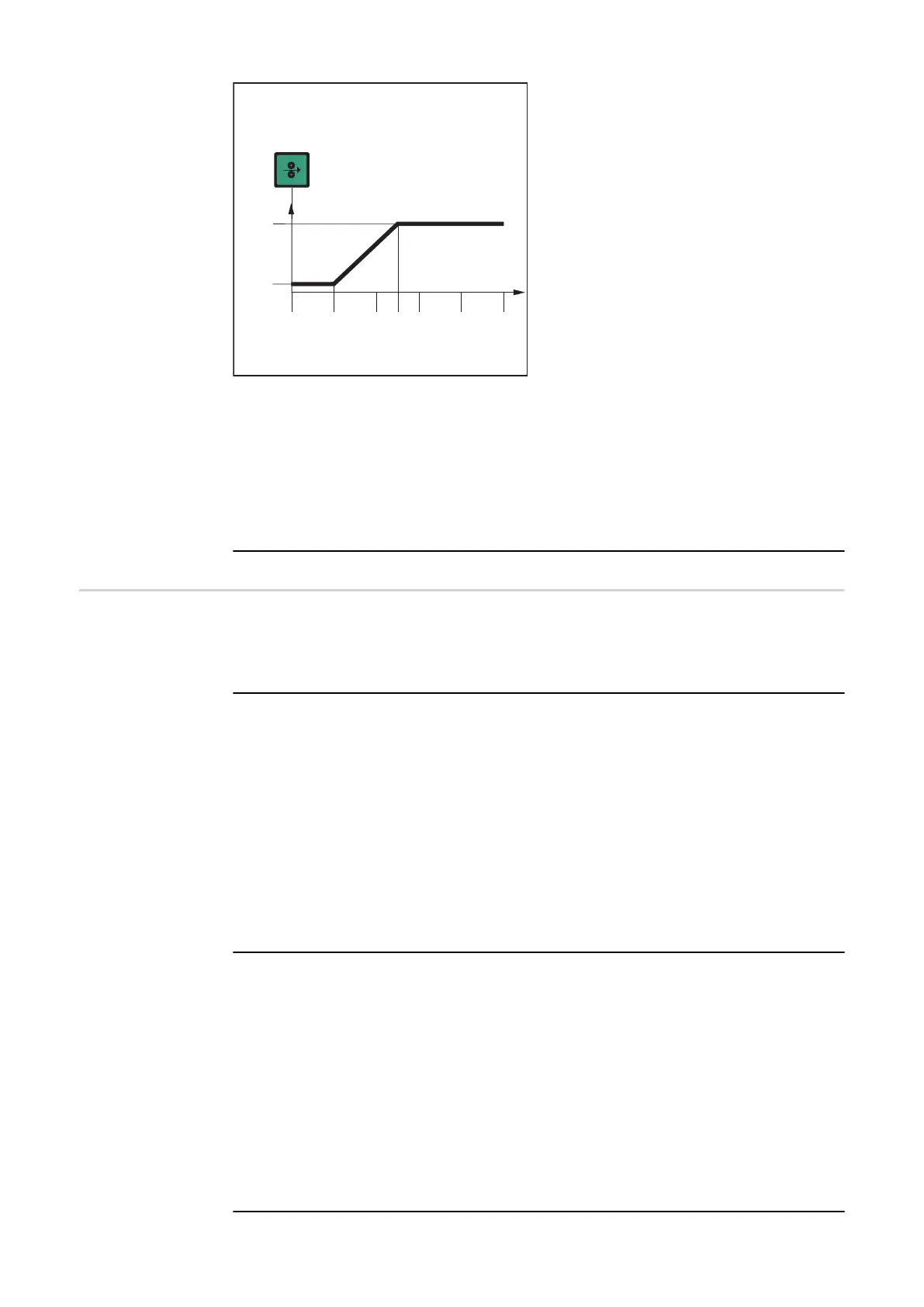

Time-path of the wire speed when the digital input sig-

nal “Wire retract“ is set

(1) Wire inching signal

- Signal remains for up to one se-

cond: Irrespective of what value has

been set, the wire speed remains at 1

m/min or 39.37 ipm for the first second.

- Signal remains for up to 2,5 se-

conds: After one second, the wire

speed increases at a uniform rate over

the next 1.5 seconds.

- Signal remains for more than 2.5 se-

conds: After a total of 2.5 seconds, the

wire starts to be fed at a constant rate

equal to the speed set for the parame-

ter “Wfi“.

IMPORTANT!

If the input signal “Cold wire disable“ is also set, then the output signal “wire speed“

applies to the retract speed, rather than “Wfi“.

The digital input signal “wire retract“ starts retracting the wire immediately with the analog

command value for the wire speed. In this case, the figure does not apply.

Touch sensing

IMPORTANT!

The “Touch sensing“ function is only supported by power sources with serial num-

bers 2.65.001 and above.

The “Touch sensing“ signal can be used to indicate that the welding wire/gas nozzle has

made contact with the workpiece (short-circuit between workpiece and welding wire/gas

nozzle).

If the “Touch sensing“ signal is set, the control panel on the power source shows “touch“.

There will be a voltage of 30 V on the filler wire/gas nozzle (current limited to 3 A).

The fact that a short-circuit has occurred is transmitted to the robot control via the “arc sta-

ble“ signal (see “Output signals“).

IMPORTANT!

Output of the “arc stable“ signal takes about 0.5 s longer than the duration of the

short-circuit current.

No welding can take place while the “Touch sensing“ signal is set. To interrupt the welding

process for position detection:

1. Set the “Touch sensing“ signal using the robot control

2. Power source stops welding after the set burn-back time has elapsed (can be set in

the power source set-up menu)

3. Carry out position detection

IMPORTANT!

If the position is to be detected when the workpiece touches the gas nozzle (instead

of the filler wire), connect the gas nozzle to the welding current lead using an RC el-

ement (see Fig. „Wire inching“).

(2) vD (m/min / ipm)

t (s)

123452,5

1

Fdi

(1)

Loading...

Loading...