26

Functional principle

Operating Princi-

ple

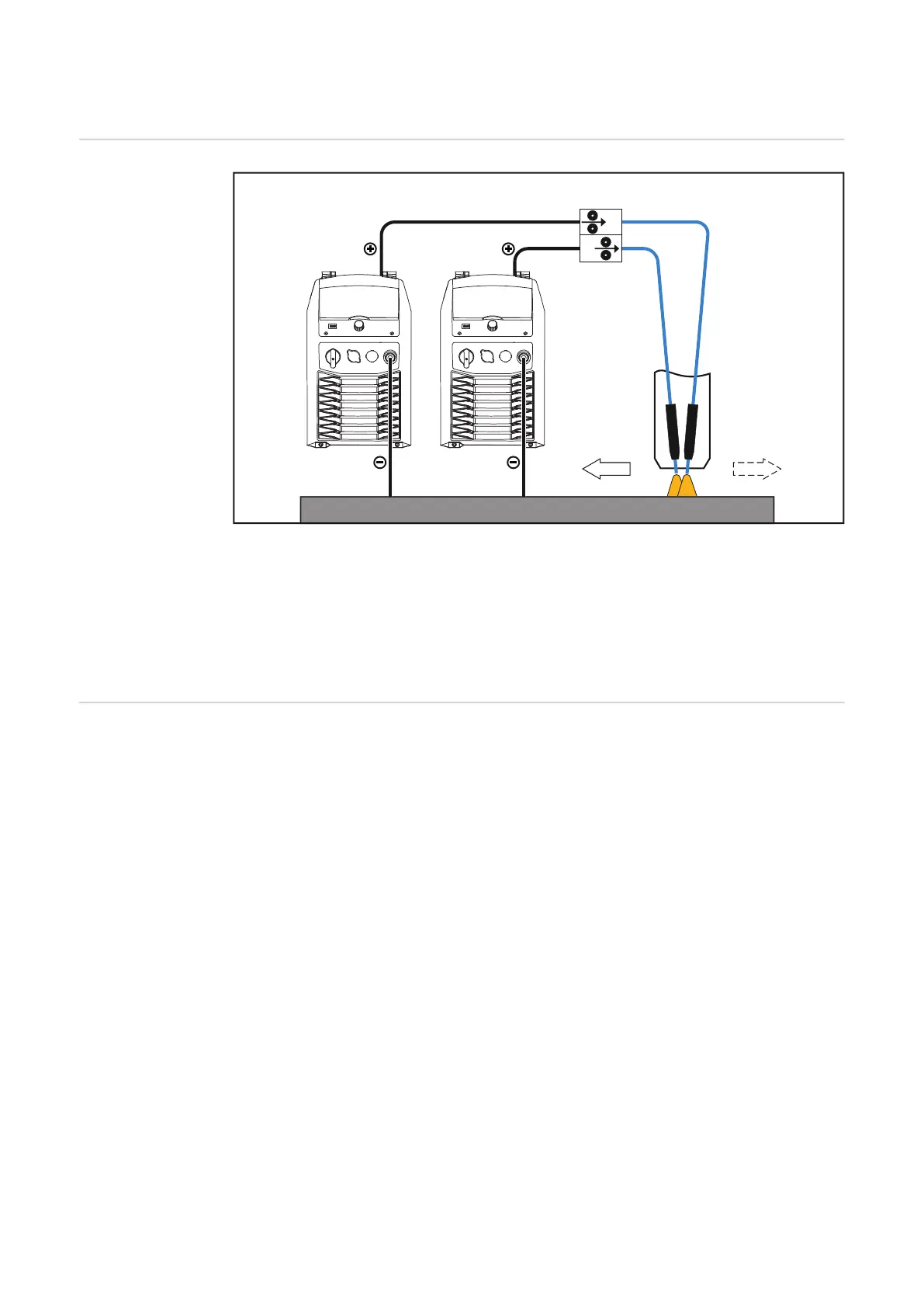

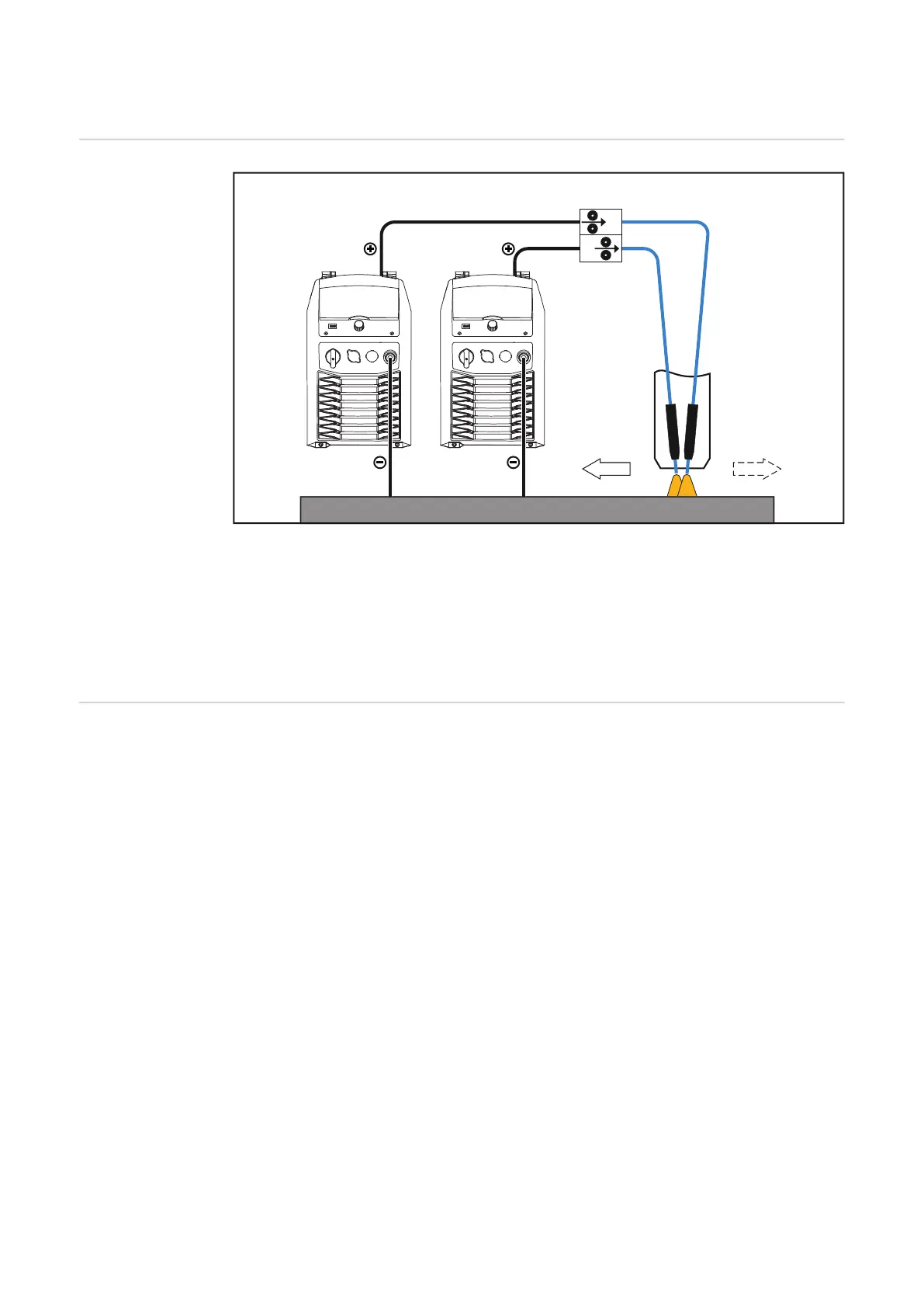

- Two wire electrodes (4) and (5) are welded in a weld pool in a shielding gas environ-

ment.

- The welding process is carried out via two independent power sources (1) and (2).

The power sources are synchronized by the TWIN Controller.

- The wirefeed is carried out via a wirefeeder (3) with two drive units.

- The two wire electrodes are brought together in the welding torch so that there are two

independent welding potentials (6).

Lead power

source and trail

power source

In the TWIN welding process, the two power sources are referred to as the lead power

source and trail power source.

- The lead power source is defined by the welding direction.

- During pulsed-arc welding, the lead power source stipulates the frequency for the trail

power source.

- When seen in the direction of welding, the wire electrode of the lead power source is

the front wire electrode.

- If the welding direction changes and the torch position remains the same, then the trail

power source becomes the lead power source.

- The robot controls define lead and trail using 2 bits. Depending on the result of this

process, lead or trail will also be displayed on the power source.

(1) (2)

(3)

(4) (5)

(6)

Loading...

Loading...