42

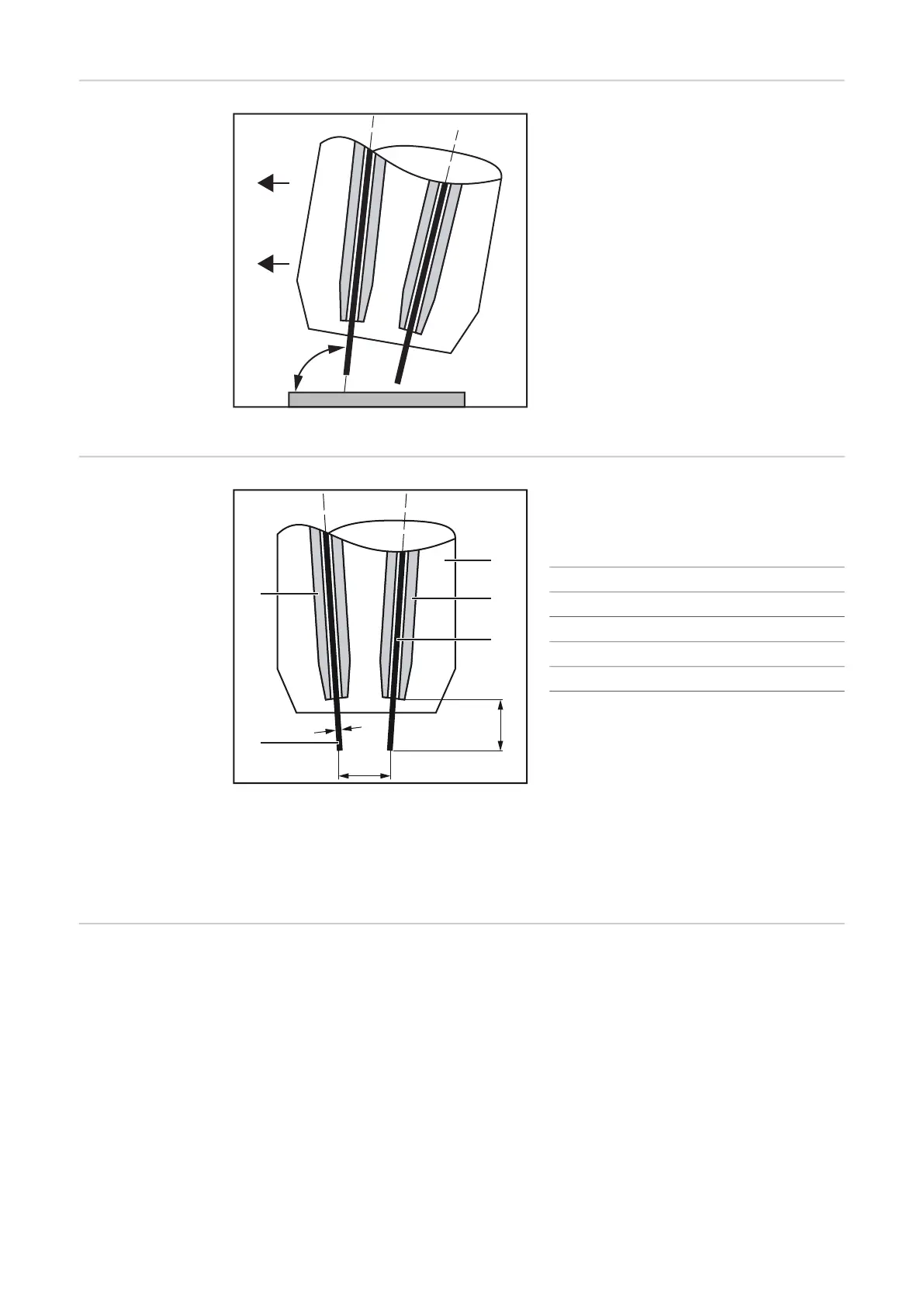

Work angle of the

welding torch

Work angle of welding torch neutral to slightly leading

Select the work angle of the welding torch

so that the lead wire electrode (= wire elec-

trode of the lead power source) is in a neu-

tral to slightly leading position.

approx. 90–100° for steel applications

approx. 100–115° for aluminum applicati-

ons

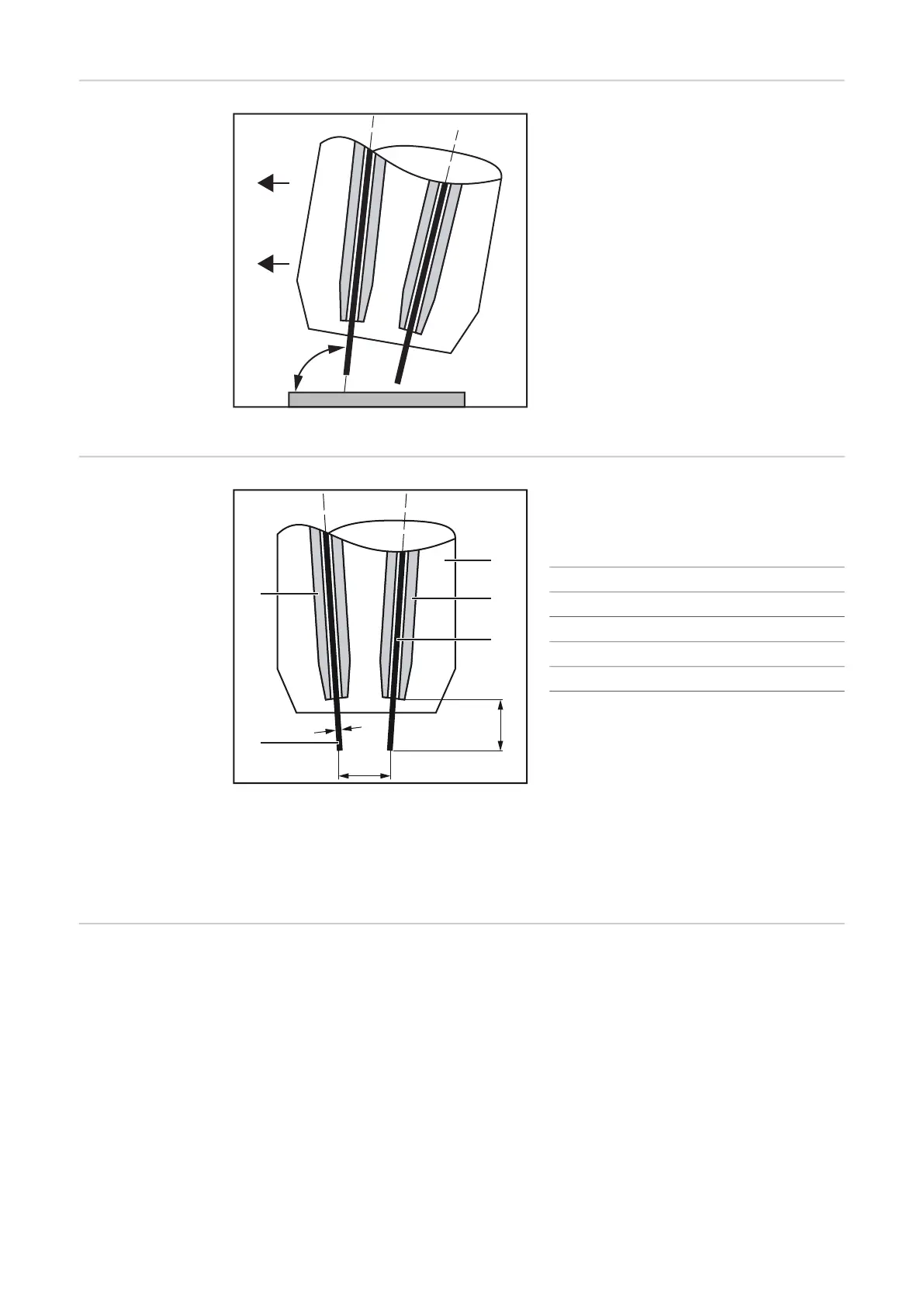

Stick out

Stick out (SO) and distance of the wire elec-

trodes depending on the diameter (D) of the

wire electrode:

(1) Wire electrode 1

(2) Contact tip 1

(3) Gas nozzle

(4) Contact tip 2

(5) Wire electrode 2

* The distance of the wire electrodes depending on the tilt angle of the contact tips

and the stick out can be found in the technical data from page 98.

TWIN mode The robot controls use the signals "Operating mode TWIN System Bit 0" and "Operating

mode TWIN System Bit 1" to define

- the lead and trail process line in TWIN mode

- the active process line in single wire mode

D [mm / inch] SO [mm / inch]

1.0 / 0.039 15 / 0.591

1.2 / 0.047 17 / 0.669

1.4 / 0.055 18 / 0.709

1.6 / 0.063 21 / 0.827

Loading...

Loading...