47

EN-US

Single wire (with

a TWIN welding

torch):

PMC/Pulse/LSC/

Standard

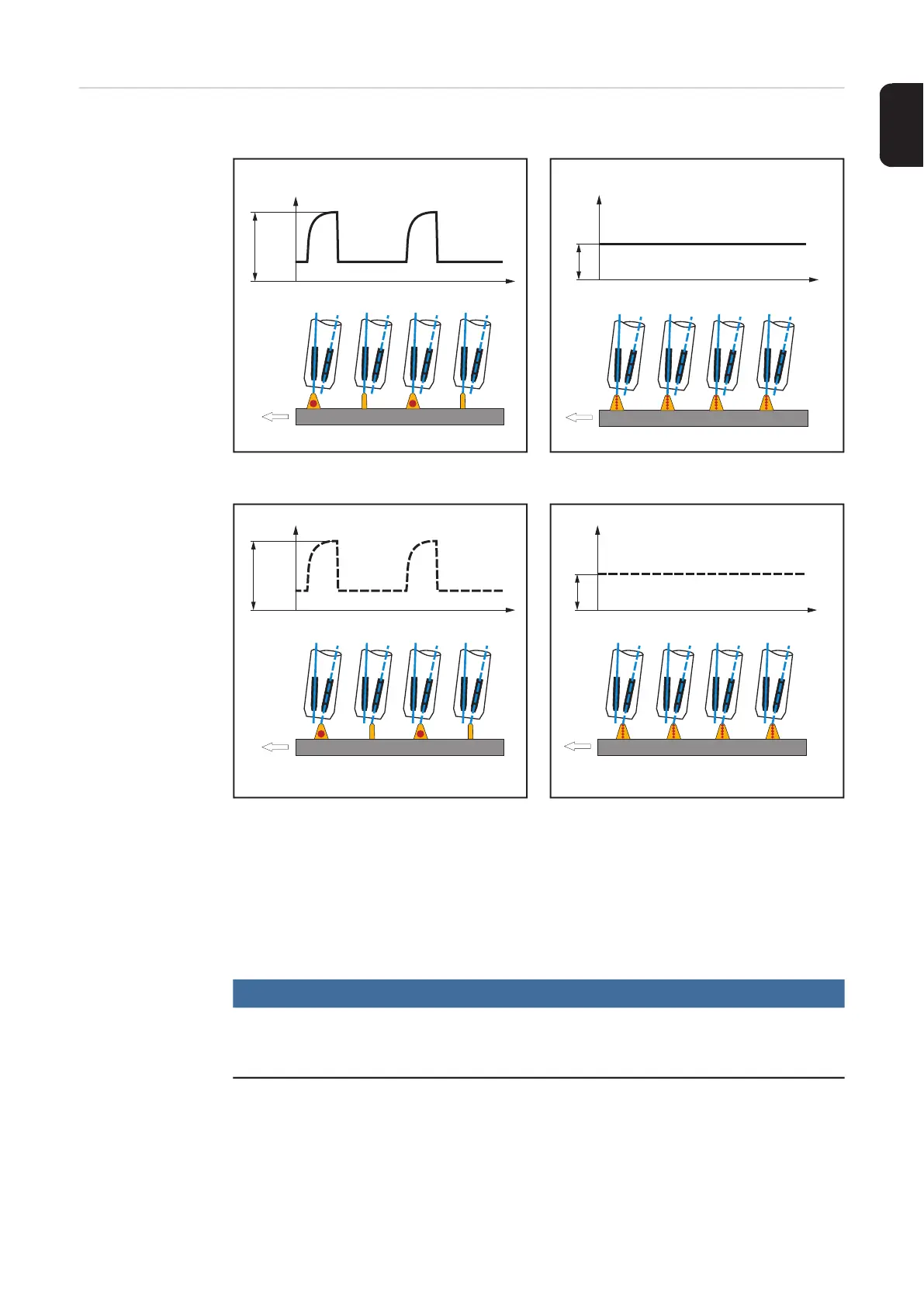

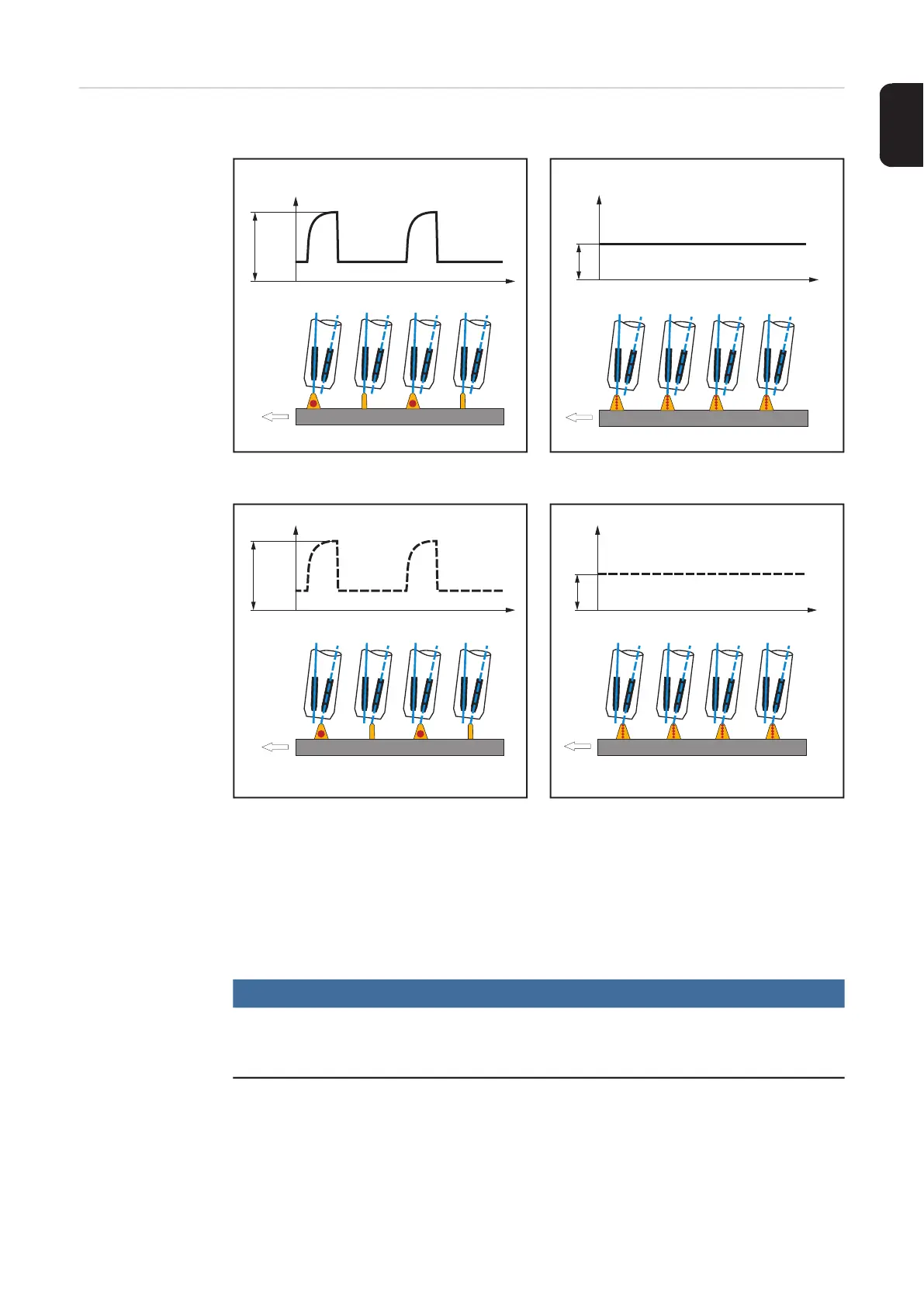

Welding current time curves and schematic representation of the material transition

PMC/Pulse - lead power source LSC/Standard - lead power source

PMC/Pulse - trail power source LSC/Standard - trail power source

Single wire welding

In single wire welding, a signal is emitted by the robot controls, meaning that only one pow-

er source welds.

Depending on the torch position or restricted position of the weld seam, the single wire

welding can be carried out by the lead or trail power source. The second power source

pauses.

NOTE!

In order to ensure a full gas shield during single wire welding with TWIN welding

torches, the solenoid valve for the pausing power source is open.

The solenoid valve is controlled via the power source.

PMC, Pulse, LSC and Standard arcs are possible during single wire welding as long as the

appropriate welding package is available on the power source. It is not necessary to

change the welding torch.

t (s)

I (A)

I

L

I

T

= 0

t (s)

I (A)

I

T

I

L

= 0

Loading...

Loading...