82

Preparing TWIN Wirefeeder for Operation

General The feed rollers are not inserted in the system when first delivered.

In order to guarantee optimum feeding of the wire electrode, the feed rollers must be ad-

justed to the wire diameter and the wire alloy to be welded.

NOTE!

Danger due to deficient feed rollers.

This can result in poor-quality weld properties.

► Only use feed rollers which match the wire electrode.

An overview of the available feed rollers and their possible uses can be found in the Spare

Parts Lists.

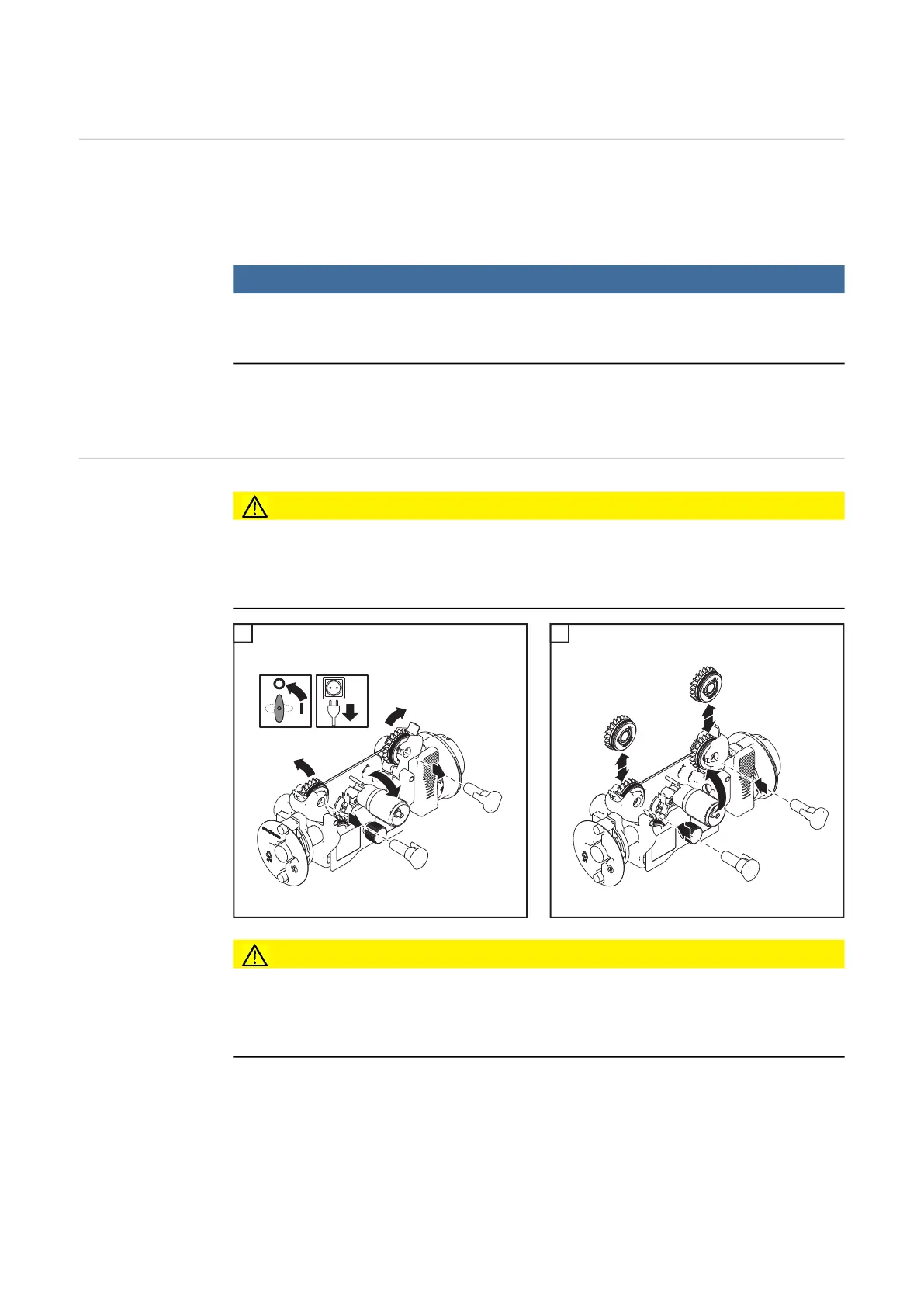

Inserting/Chang-

ing Feed Rollers

CAUTION!

Danger due to feed roller holders shooting upwards.

Serious injuries may result.

► When unlocking the clamping lever, keep fingers away from the area to the left and

right of the clamping lever.

1 2

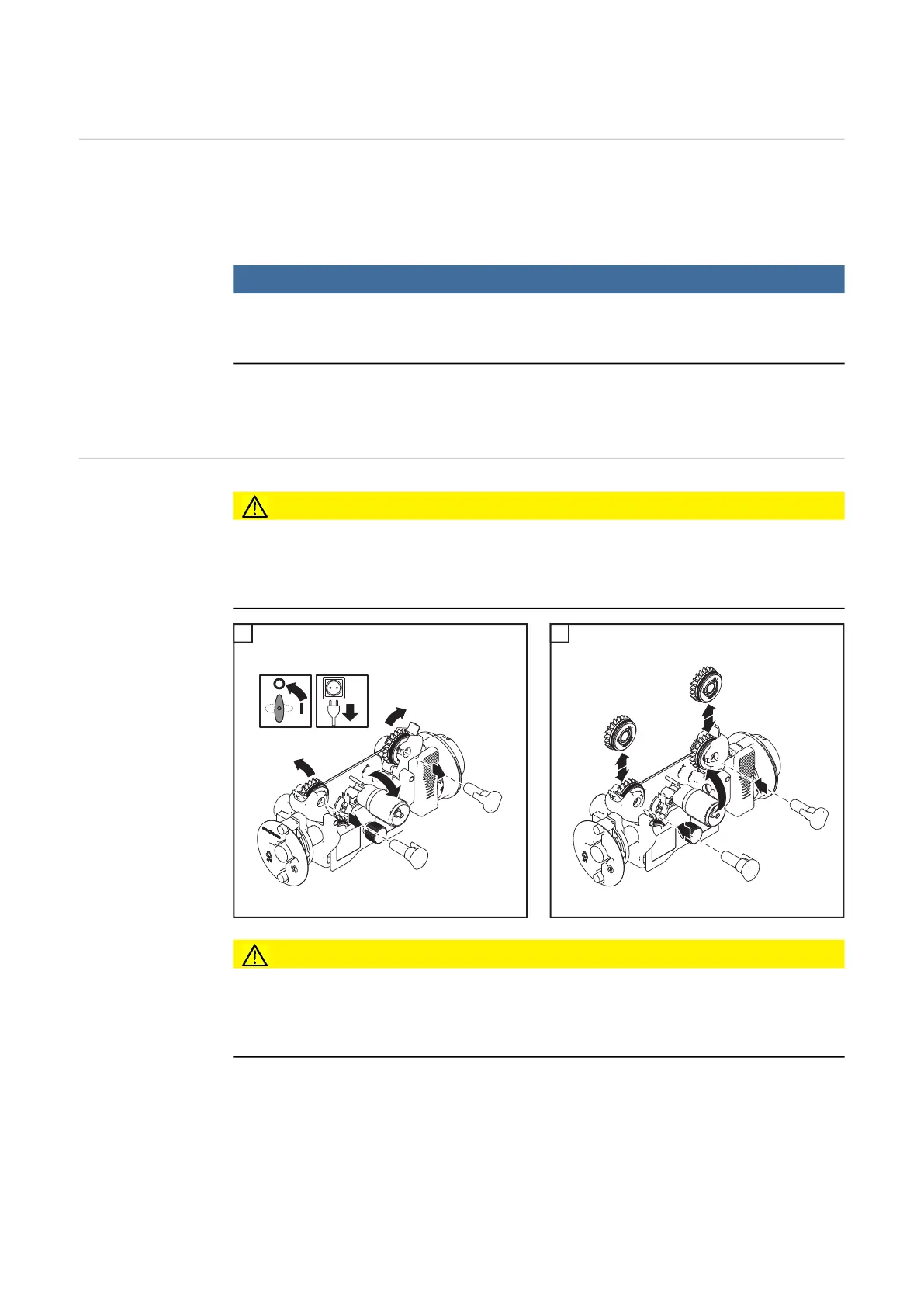

CAUTION!

Danger due to open feed rollers.

Serious injuries may result.

► After inserting/changing the feed rollers, always install the protective cover of the 4 roll-

er drive.

1

6

3

31

2

4

5

7

Loading...

Loading...