80

Dimension 200

8.

Place the tool height gage on the surface of the mats under the

bit. Use the Z axis knob to lower the tool until it just touches

the gage.

9.

Press Z INIT once. This lifts the Z axis once and locks it. The

tool is now initialized to the table surface.

10.

Using the arrow keys, move the carriage to the extreme lower

left corner (absolute 0,0 or the orientation point) of the table

and set Job Home Position.

11.

In ART Path, click on Output. The Job Output dialog box

appears. (Make sure that no pre-position moves have been

entered.)

12.

Click on Rout.

13.

Press START/STOP three times to begin the grid. This

displays the header and tool messages and begins routing.

Material Selection and Preparation

The Dimension 200 can draw on any kind of material suitable for a

ballpoint pen, and cut virtually any routable material including

those listed below.

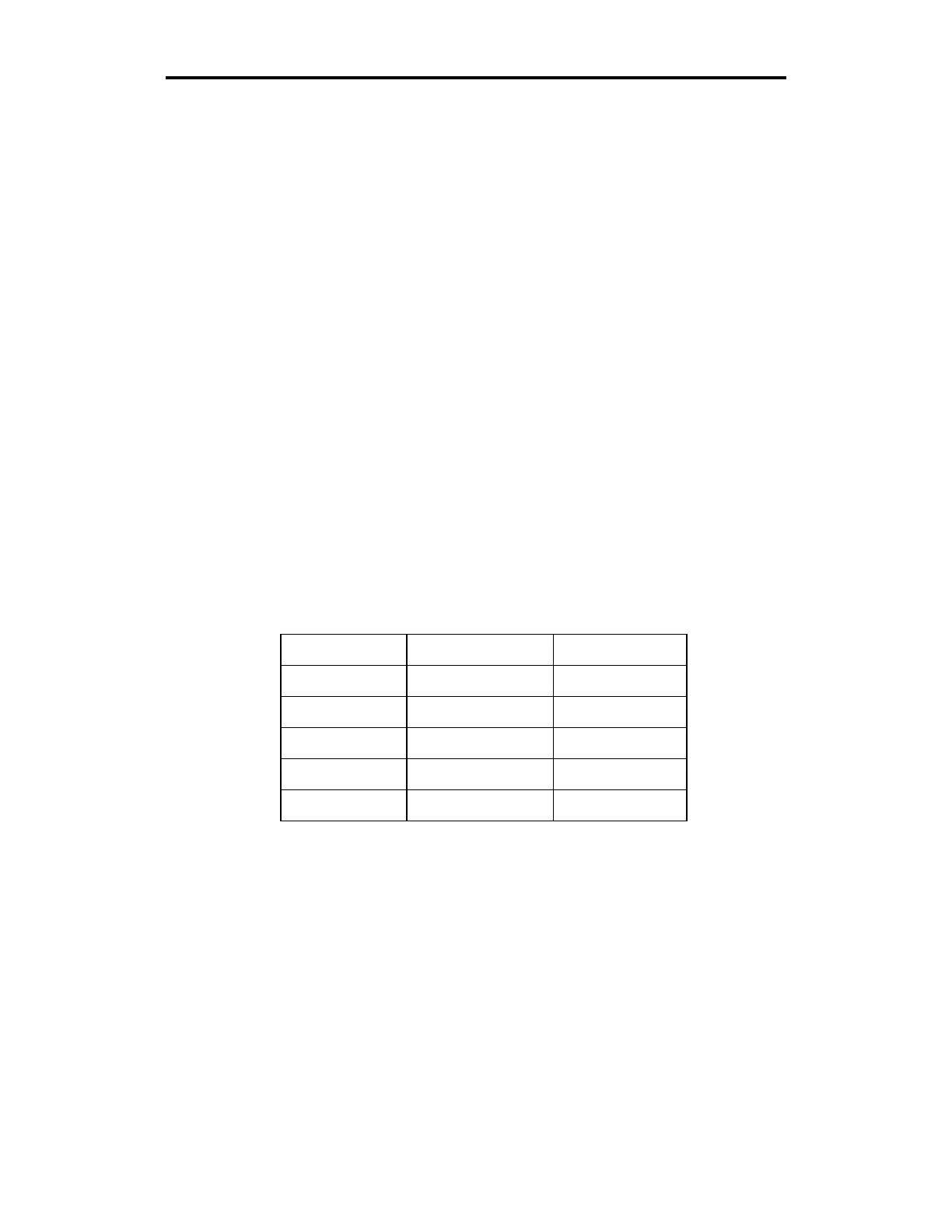

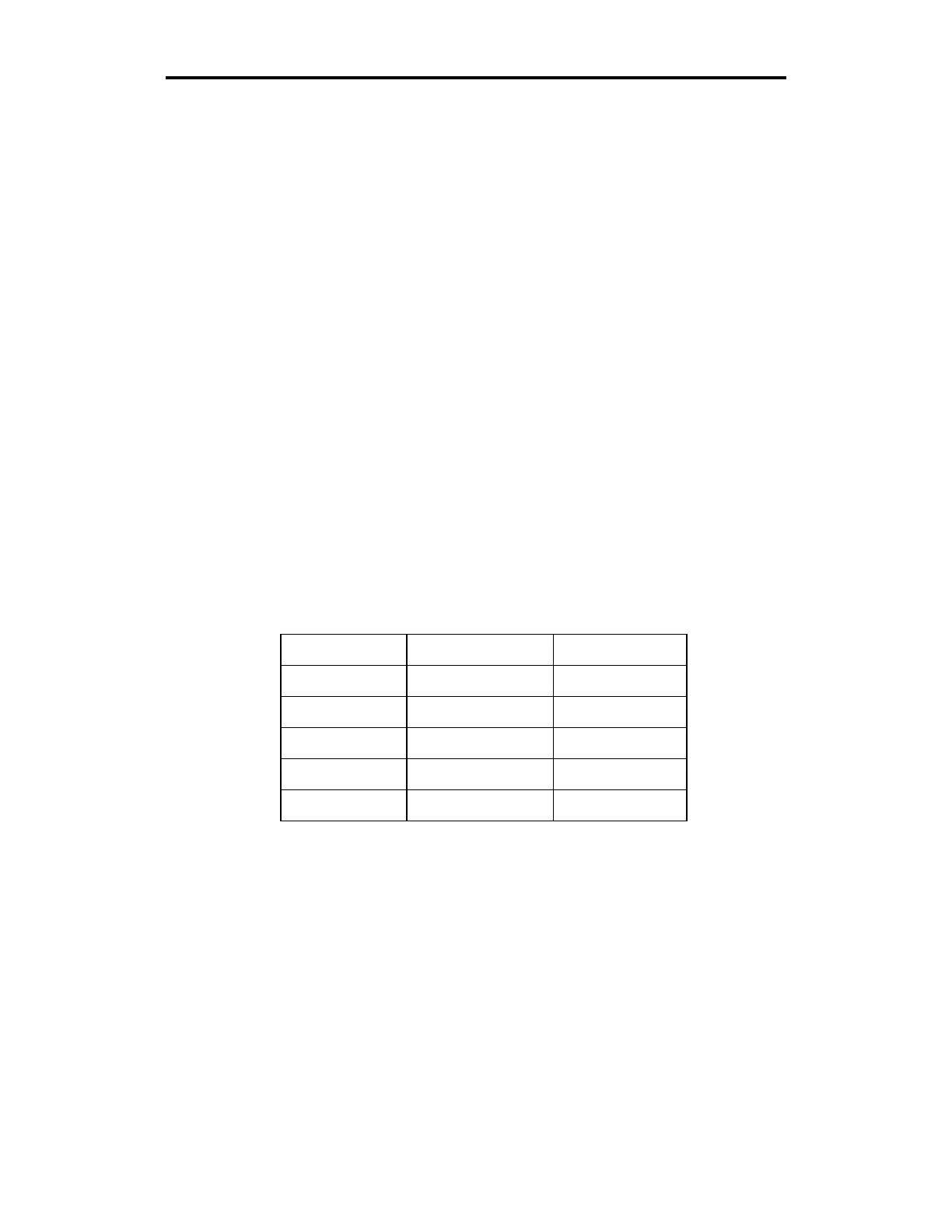

ROUTABLE MATERIALS

Plastics Woods Metals*

Acrylic Hard Aluminum

Polycarbonate Soft Brass

Phenolic Masonite Copper

Styrene Plywood Bronze

Foam Board Particle Board

* All metals require use of the Mist Coolant system.

CAUTION: Steel or stainless steel is not recommended for use

with the Dimension 200.

Loading...

Loading...