PREVENTIVE MAINTENANCE

General

Therequiredmaintenanceintervalwilldependlargelyonthequalityofthe

incoming water and how often the machine is used. The maintenance inter-

val will have to be determined in each individual case. We recommend that

thestatedmaintenanceoperationsaredoneatthespeciedintervals.Wealso

recommend that a function check is done once or twice a year.

For repairs or adjustments, see under Repair and adjustment.

Periodic maintenance

This may only be done by authorized personnel.

The machine is connected to the electricity supply and some components are live.

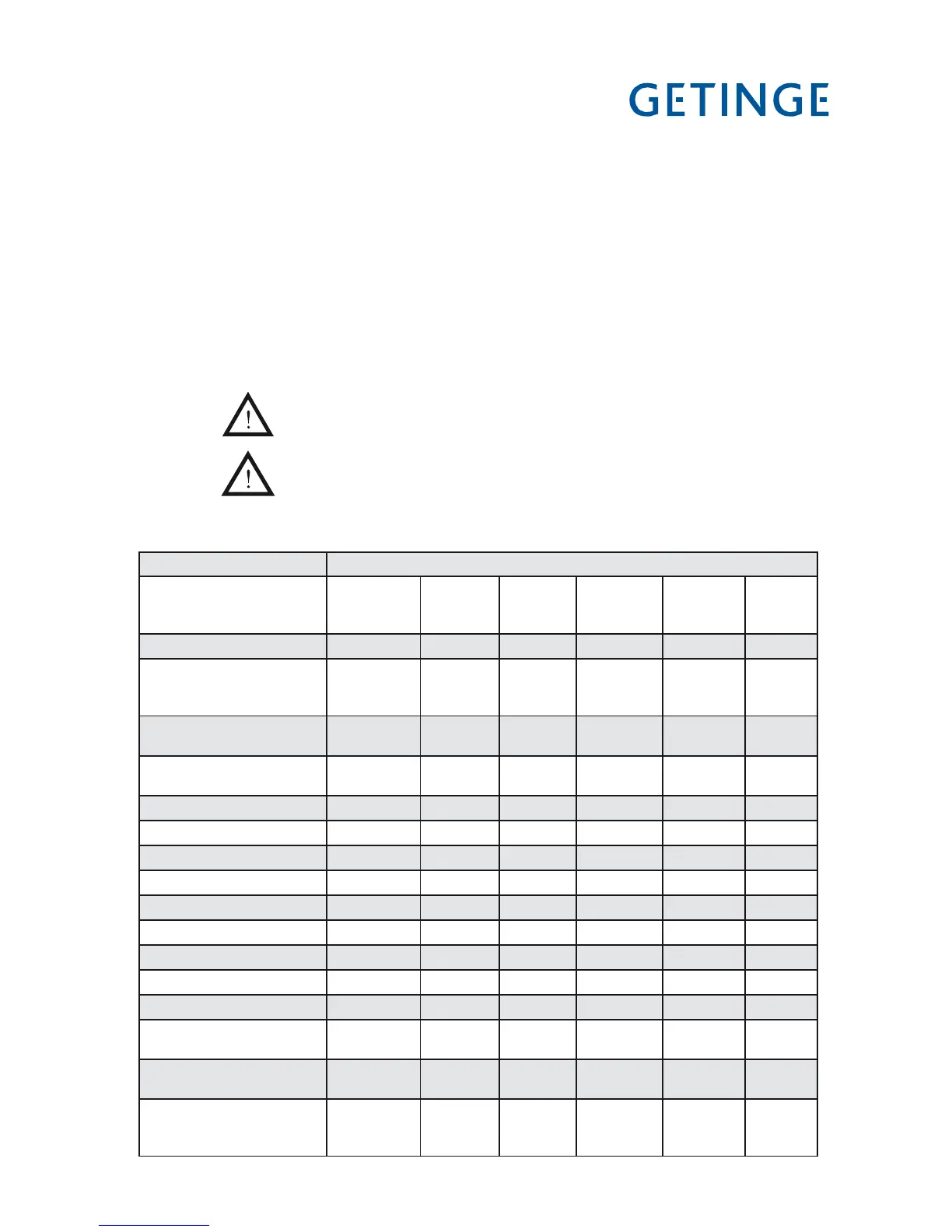

Component Interval

Check

yearly

Replace if

necessary

Replace

yearly

Replace

every other

year

Replace

after 1000

hours

Replace-

ment

time

Door seal

• • 1 h

Hoses between dosing

pump and detergent

container

• • 1 h

Hose between dosing

pump and machine

• • 1 h

Filter in incoming media

• • 1 h

Overheat protection

• • 1 h

Hose in hose pump

• • 1 h

Spray arm bearings

• • 1 h

Sterile filter in dryer

• • 2 h

Hoses to dryer

• • 2 h

Check valve in dryer

• • 1 h

Check valve in waste

• • 1 h

Fan to dryer

• • 3 h

Ribbon to printer

• • 10 min

Manual door: Spring on

door closing

• 4 h

Automatic door: Crush

protection on door closing

• 1 h

Make sure that the power

cables are firmly attached

in their sockets.

•

Loading...

Loading...